Whole-range combustible gas detector

A gas detector, full-range technology, applied in the direction of material resistance, can solve problems such as complex maintenance methods, discontinuous range, high-concentration and low-concentration range discontinuity, etc., to solve the problem of full-range measurement of a single component, and to solve double-value ” problem, eliminating interruptions and jumping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

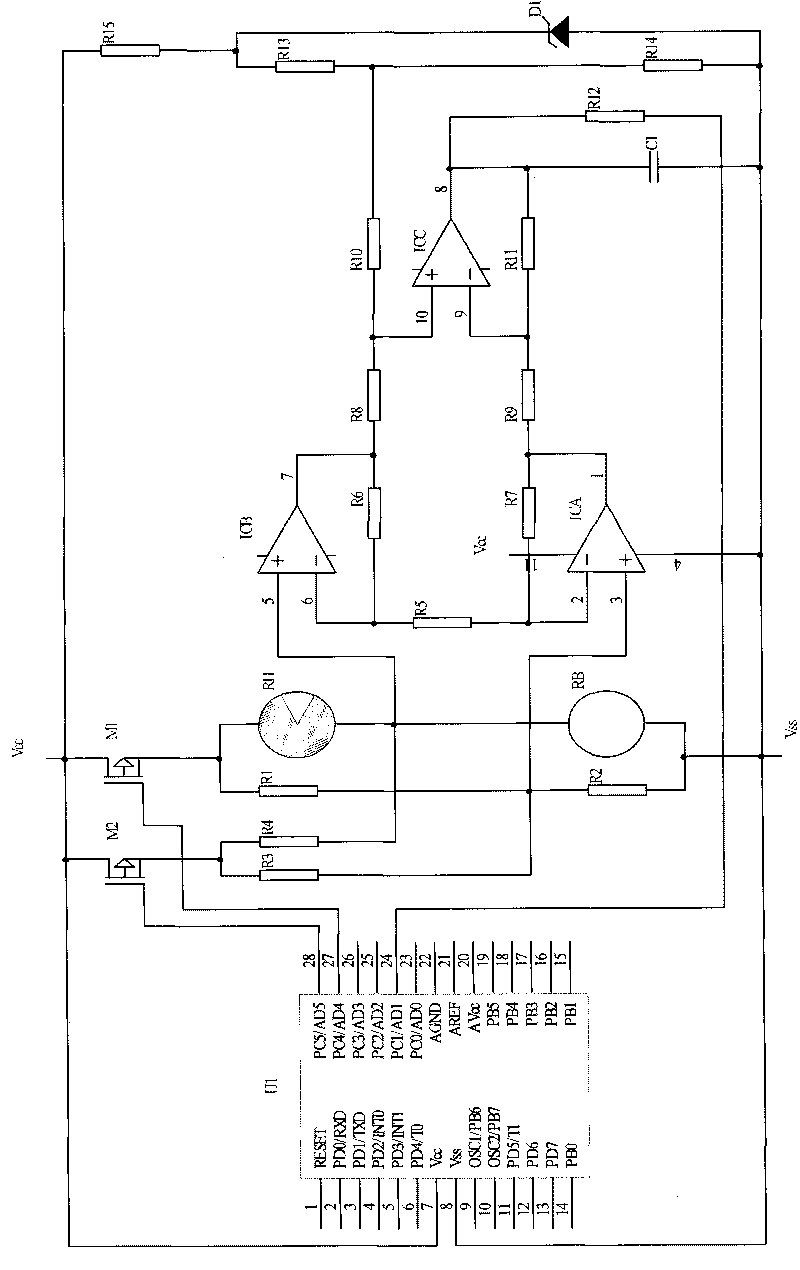

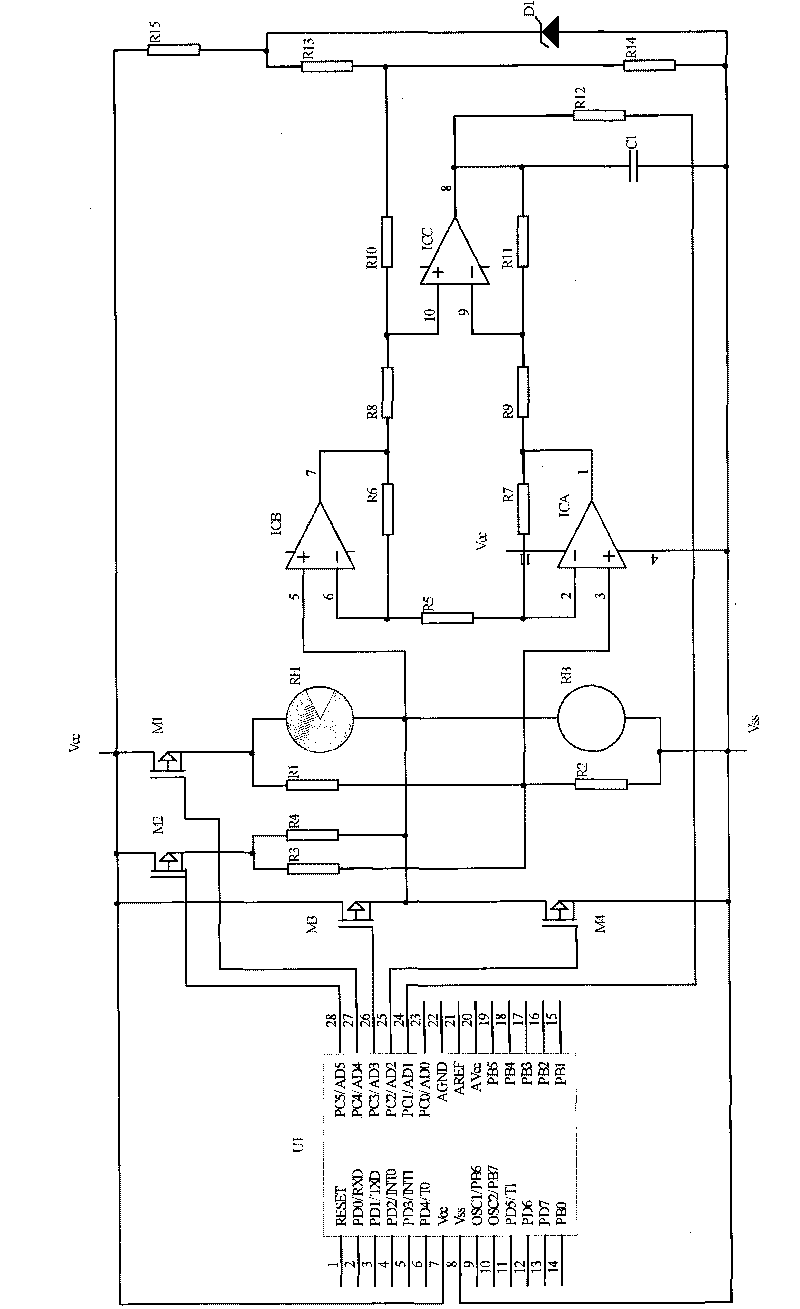

[0011] figure 1 It is the circuit schematic diagram of Embodiment 1, the power supply voltage is 2.0-3.5V (depending on the working voltage of the catalytic element), U1 can use MAGE8, PIC16F877, MSP430F413 and other single-chip microcomputers, and the op-amp can be an ordinary LM324 , The switching tube should choose a MOS tube with stable performance and small voltage drop. When starting up, M1 is turned on and M2 is turned off. In the figure, the sensitive element RH, the compensation element RB and the resistors R1 and R2 form a measurement bridge, and the midpoint of the two arms is connected to the instrument amplifier circuit composed of ICA, ICB, ICC and some resistors. When the combustible gas reaches the surface of the sensitive element and the compensation element, under the action of oxygen in the air, flameless combustion occurs on the surface of the sensitive element, the resistance value of the platinum wire of the sensitive element increases, and the balance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com