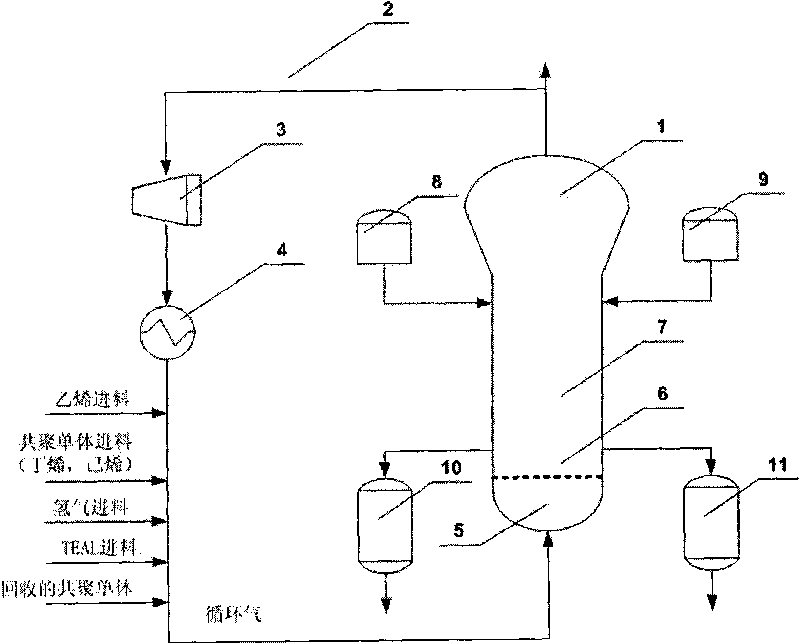

Dynamic fault diagnostic method of polymer aggregation in gas-solid fluidized bed reactor

A fluidized bed reactor, fault diagnosis technology, applied in the processing of detection response signals, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as agglomeration faults, and achieve the effect of convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

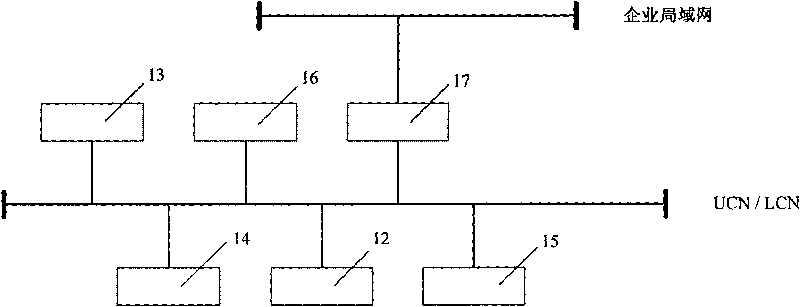

Method used

Image

Examples

Embodiment Construction

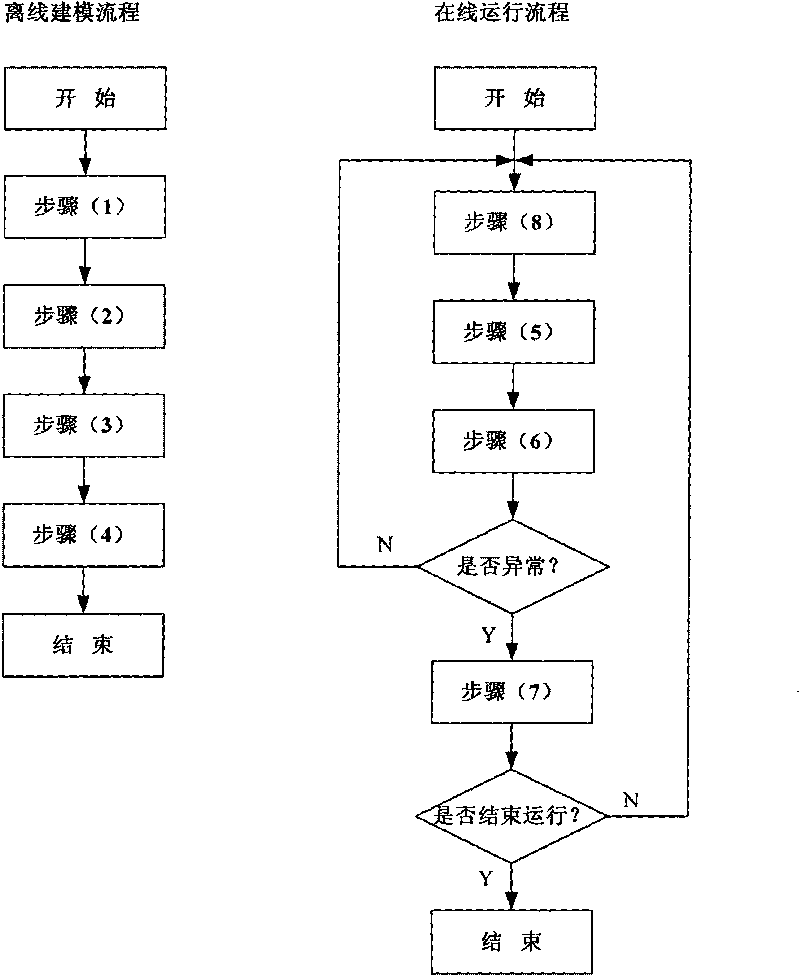

[0031] The dynamic fault diagnosis method of polymer agglomeration in the gas-solid fluidized bed reactor of the present invention comprises the following steps:

[0032] 1. Based on the analysis of the process operation mechanism and previous fault treatment reports, select the following 14 key variables that affect the caking fault: 11 wall temperatures of the reactor from bottom to top T_RX_B~T_RX_H to T_RX_J~T_RX_M, reaction The bulk density of the upper part of the reactor D_Upper, the bulk density of the lower part of the reactor D_Lower, the pressure drop of the reactor distribution plate P_RXplate, construct the fault detection variable set [T_RX_B T_RX_C T_RX_DT_RX_E T_RX_F T_RX_G T_RX_H T_RX_J T_RX_K T_RX_L T_RX_M D_Upper D_LowerP_RXplate]. According to the requirements of dynamic principal component analysis modeling, in the case of no agglomeration, according to the dynamic corresponding characteristics of the operation of the gas-solid fluidized bed reactor, three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com