Multispectral sensitization device and manufacturing method thereof

A photosensitive device and multi-spectral technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, radiation control devices, etc., can solve the problems of reduced sensitivity of filter films, lower space and energy usage efficiency than multi-layer, and inability to respond to different scenes Light and other issues, to achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

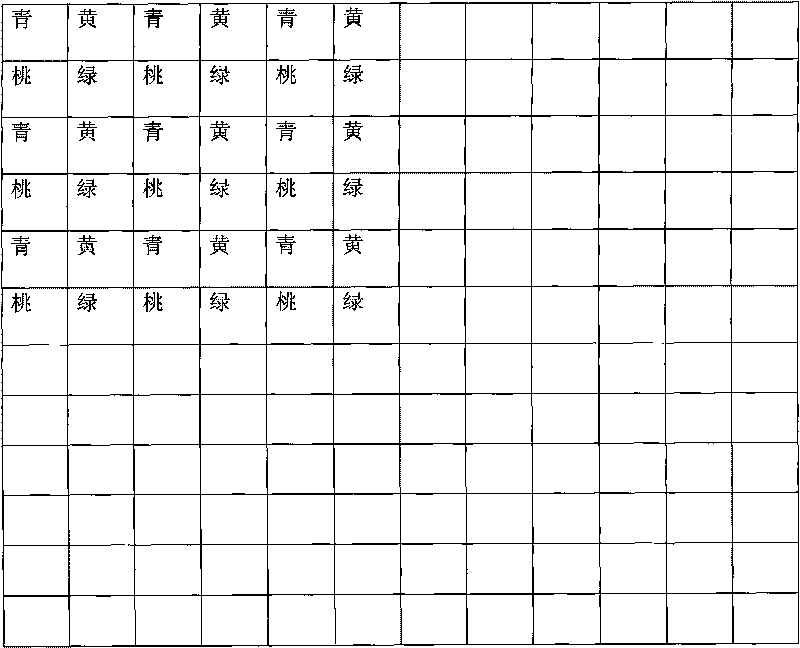

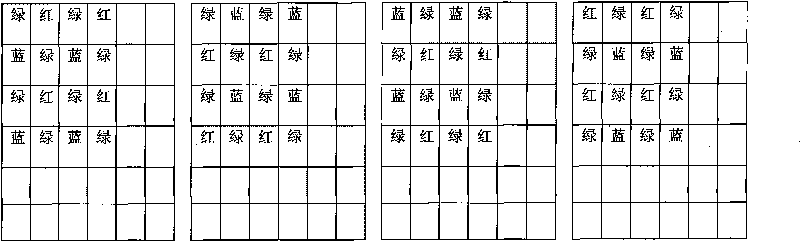

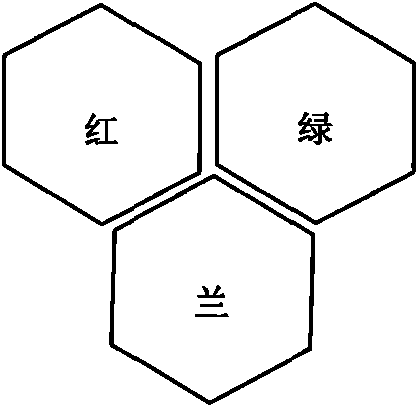

[0075] The multi-spectrum photosensitive device, manufacturing method and photosensitive system of the present invention are mainly provided with photosensitive pixel groups on each surface of the base layer having one or more surfaces, so as to obtain scenes in different directions at the same time. It should be understood that the shape of the base layer is not limited, for example, it may be rectangular, circular pie, hexahedron and so on. When the base layer is opaque, there is more selectivity in setting its shape. When the base layer is transparent, it is preferable to use a two-sided thin cuboid and hexahedron to facilitate the acquisition of corresponding pixel positions on the opposite surfaces.

[0076]The present invention will be described below by taking the base layer as a planar body (cuboid with extremely thin thickness) as an example. At this time, the photosensitive device of the present invention realizes bidirectional photosensitive, that is, photosensitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com