Electronic ballast

An electronic ballast and circuit technology, which is applied to the use of electric light sources, electrical components, gas discharge lamps, etc., can solve the problems of low efficiency of the voltage-doubling series ignition circuit, improve the success rate of one-time ignition, and improve the overall efficiency. , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

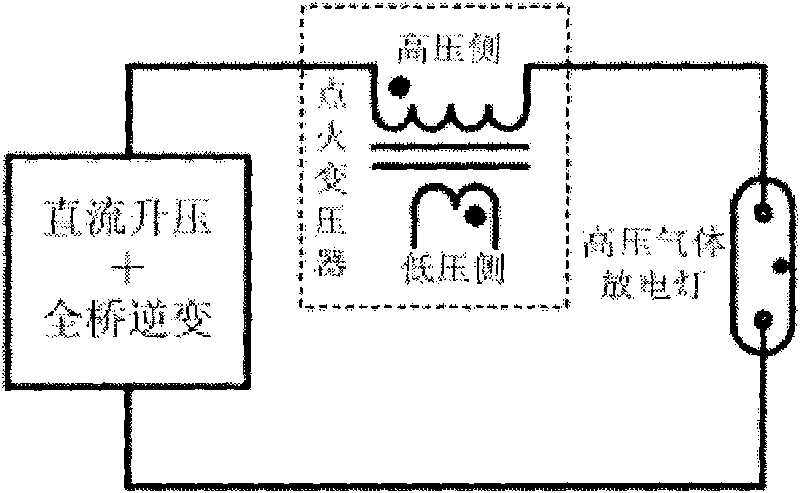

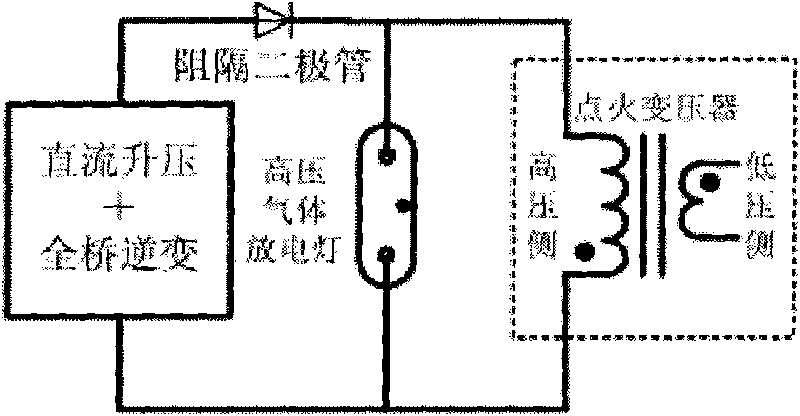

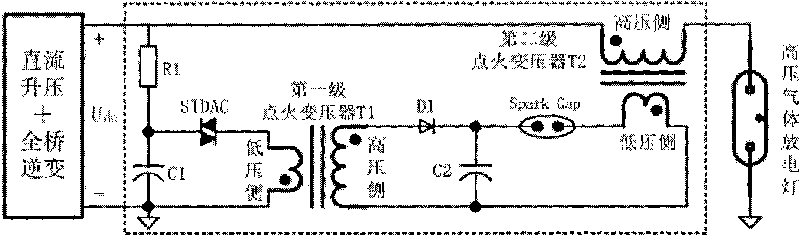

[0026] refer to Image 6 , an electronic ballast, including an input filter 2 for isolating the high-frequency interference between the storage battery 1 and the device connected in series, and a DC-DC inverter for increasing the DC voltage input to the battery 1 level. Exciter converter 4, a DC-AC full-bridge inverter circuit 6 for converting high-voltage direct current into a high-voltage square wave voltage, the front end of the input filter 2 is connected to a storage battery 1, and the DC-AC full-bridge inverter circuit 6 is connected in parallel with an arc continuation circuit 5 that temporarily provides energy for the high-pressure gas discharge lamp when the two electrodes of the high-pressure gas discharge lamp are broken down, and an ignition circuit 3 with a double-voltage parallel structure; It includes a voltage doubler circuit, a booster circuit, a blocking high-voltage diode D5, and a relay. The output end of the voltage doubler circuit is connected to a contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com