Frictional part with a zig-zag or undulating circumferential groove in the frictional surface

A technology of friction parts and friction surfaces, applied in the direction of friction linings, friction clutches, clutches, etc., which can solve the problems of limited controllability of friction devices and undesired torque transmission, etc., and achieve the effect of improving wear characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

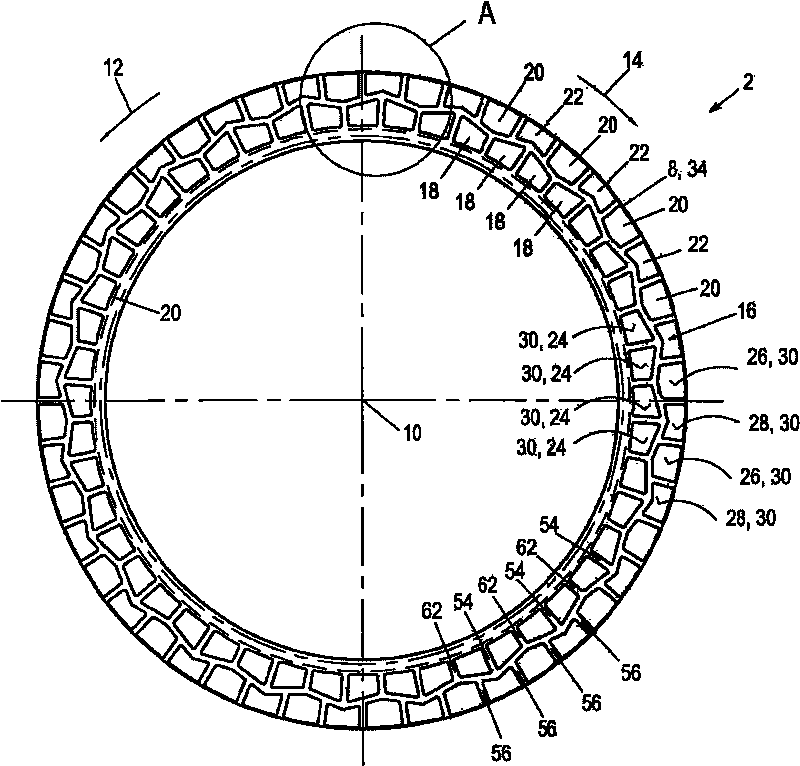

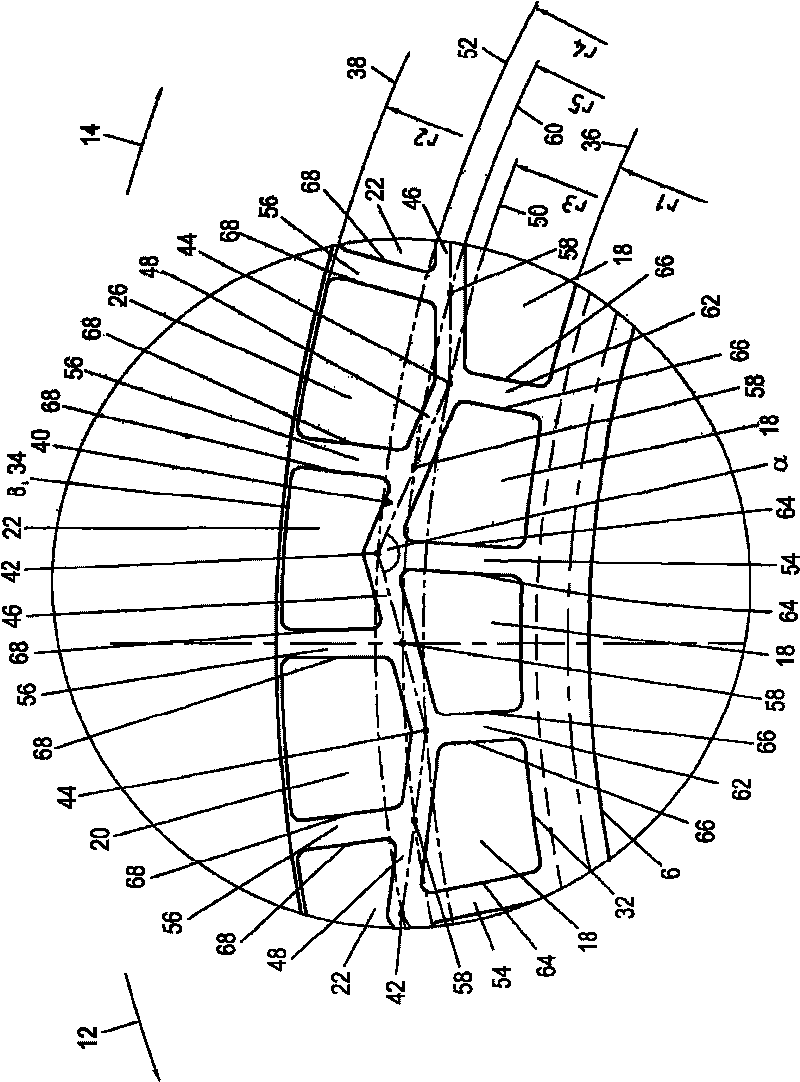

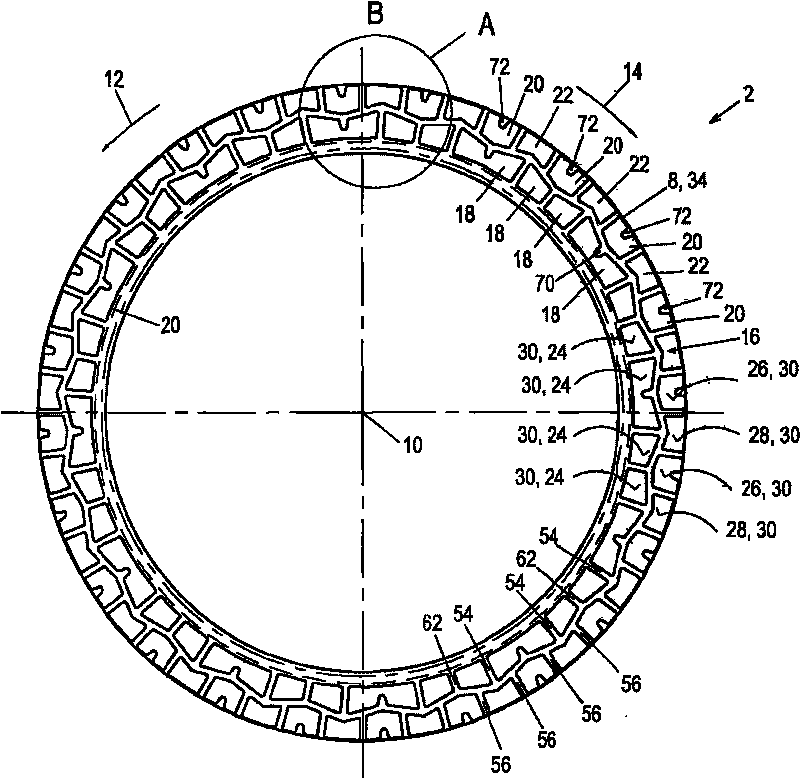

[0049] figure 1 with figure 2 A first embodiment of the friction member 2 for the friction acting device according to the present invention is shown. The friction component 2 shown in this solution is implemented as a plate for a multi-plate clutch or a multi-plate brake and has a friction lining carrier 4. The friction lining carrier 4 is embodied as an annular steel disk, which extends in the plane of the drawing and includes an inner edge 6 and an outer edge 8. Provided on the inner rim 6 is a drive profile, preferably an internal toothing, which is only schematically represented in the figures and is integral with the annular disc. The internal tooth shape is used to fixedly connect the friction member 2 to a sheet carrier in the sense of rotation, but enables the friction member 2 to move in an axial direction of the sheet carrier. The present friction member 2 is therefore a so-called inner sheet. It should be noted, however, that the friction member 2 according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com