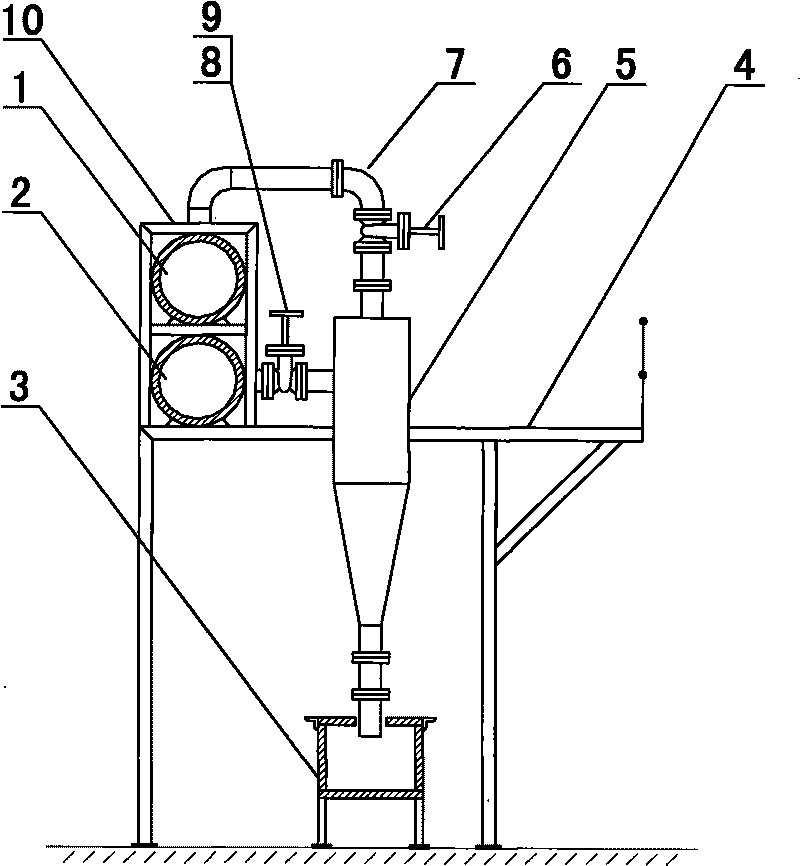

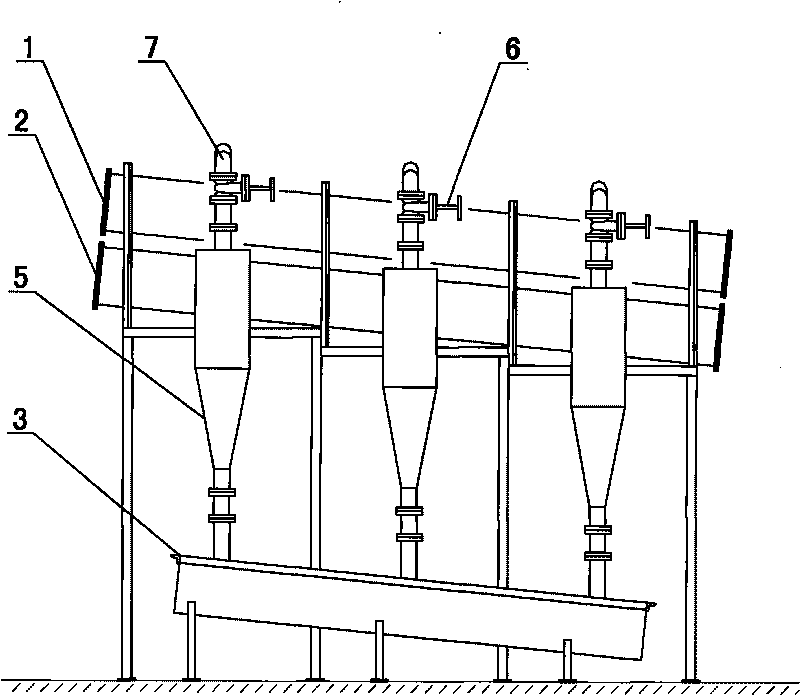

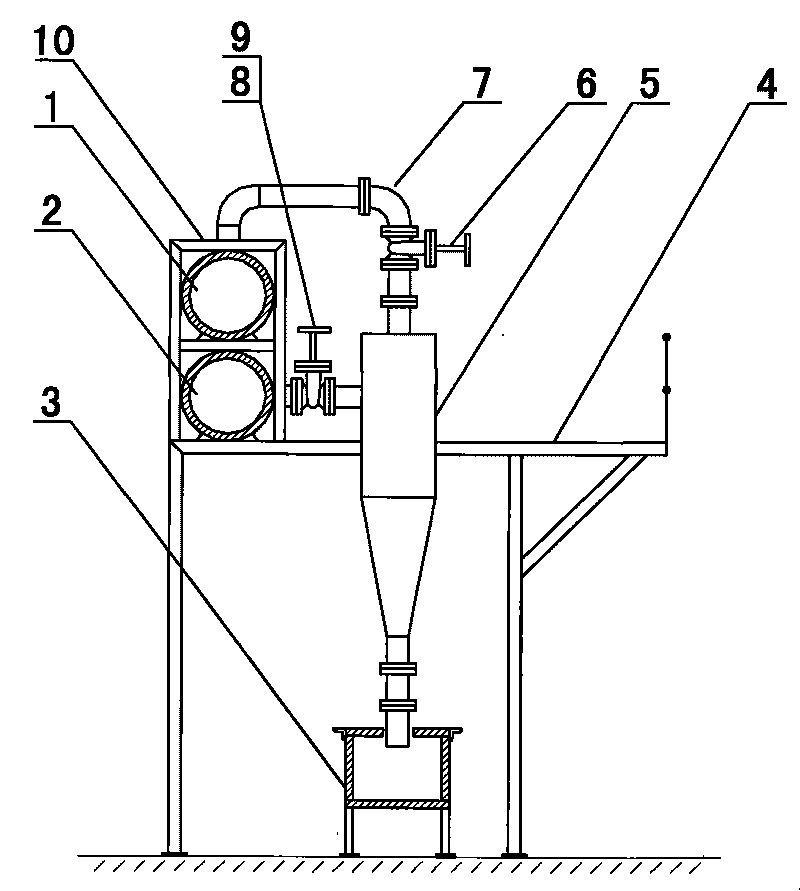

Configuration structure of hydrocyclone unit

A technology of hydrocyclone and configuration structure, which is applied in the direction of cyclone device, device whose axial direction of cyclone can be reversed, grain processing, etc. Quantity, increase the length of the configuration, the effect of the simple working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through the description of specific embodiments, but this can not be used to limit the protection scope of the present invention, those skilled in the art can make various modifications or improvements according to the basic idea of the present invention, but as long as not Anything that deviates from the basic idea of the present invention falls within the scope of the present invention.

[0022] The configuration structure of the hydrocyclone group of the present invention, wherein each hydrocyclone 5 is arranged in a straight line or in steps, and each hydrocyclone is installed on the same operating platform 4 . A valve 6 is installed on the overflow pipe 7 of each hydrocyclone 5; a valve 9 is installed on the feed pipe 8. The overflow pipe 7 of each hydrocyclone 5 is connected to the overflow main pipe 1; the feed pipe 8 of the hydrocyclone 5 is connected to the feed main pipe 2; the underflow pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com