Multi-layer sieve bend

A curved sieve and arc-shaped technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems such as the effect is not obvious, and achieve the effect of high screening efficiency, no power required, and large effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

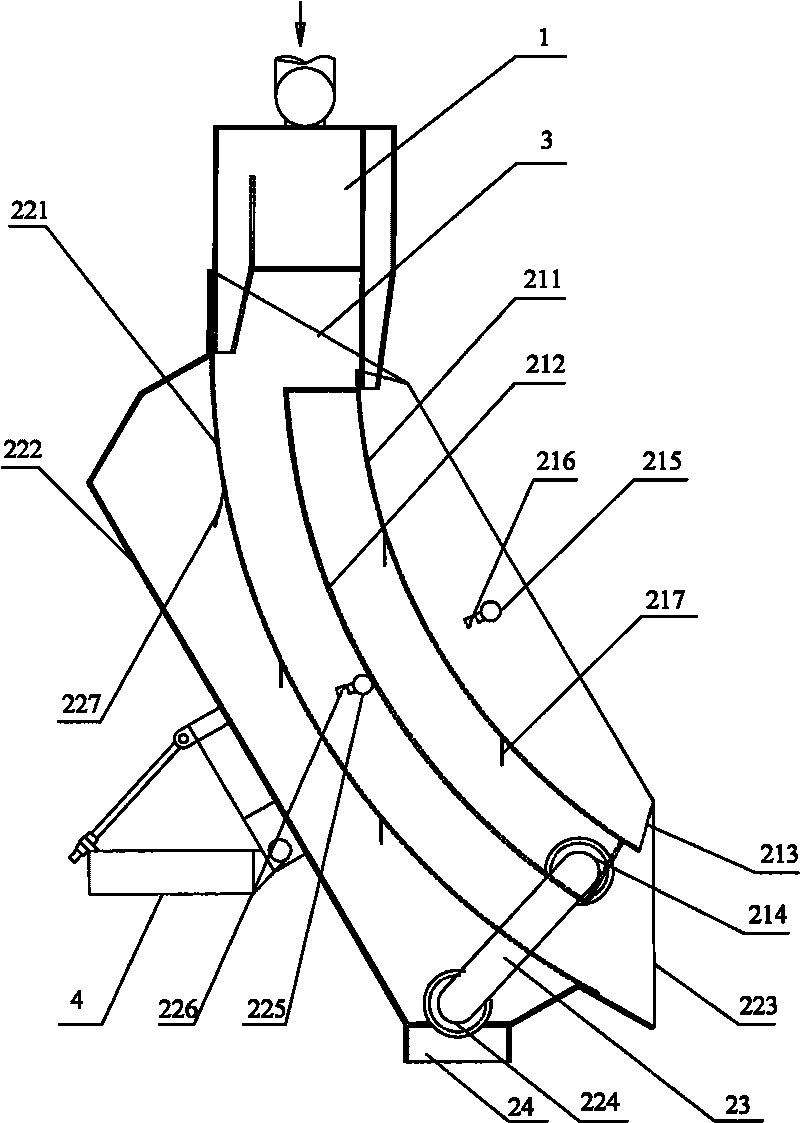

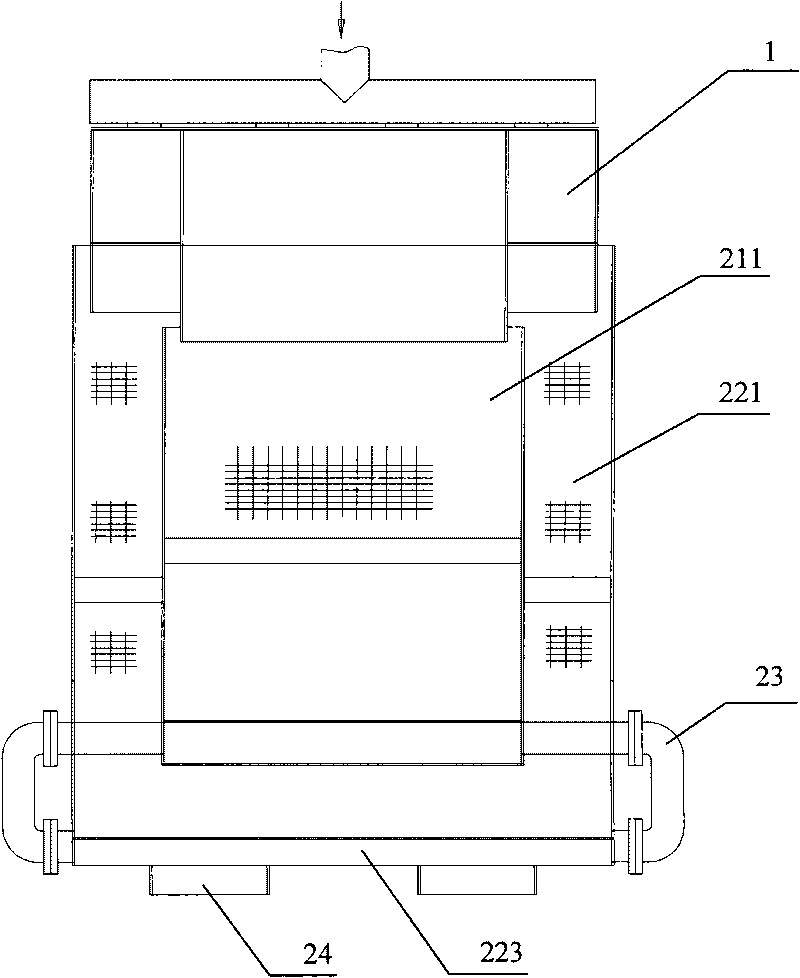

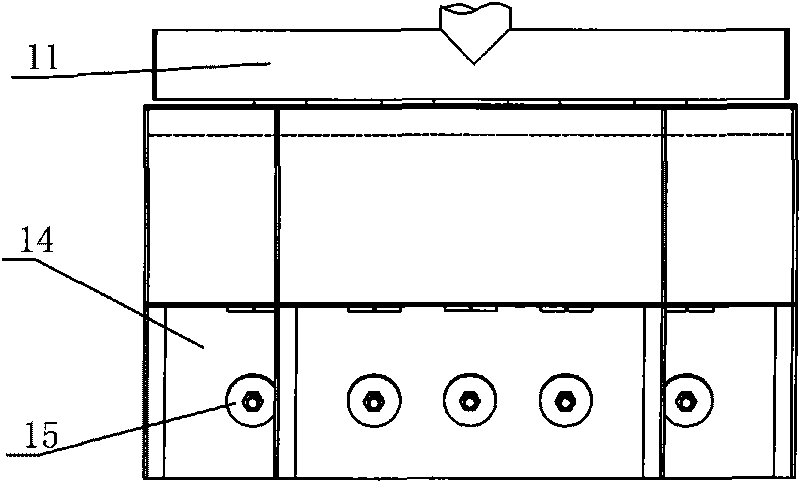

[0025] The present invention mainly solves the problem of how to greatly increase the area of the screen surface under the same occupied area under any fixed combination of curvature radius, wrap angle, screen width, and screen surface opening ratio, so as to greatly improve the classification efficiency of the curved screen. problems, as well as many parameter optimization problems that affect the classification efficiency.

[0026] Based on the above purpose, the present invention provides a multi-layer curved screen, that is, there are multiple curved screens stacked up and down to form multiple layers, leaving a predetermined space between each layer, which is used to accommodate the lower curved screen materials in. Since there are multiple arc-shaped screening layers, the feeding device is also different from the prior art. The following will be described in detail through specific examples.

[0027] see figure 1 , is a schematic side view of an embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com