Simple flexible positioning method for continuous external surface of workpiece

A technology of flexible positioning and contour surface, which is applied in the direction of positioning devices, metal processing machinery parts, manufacturing tools, etc., can solve the problems that the positioner and the positioning surface affect the openness, do not adapt to the change of the workpiece, and the operation is inconvenient for workers. Easy to use, simple shape, good open effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

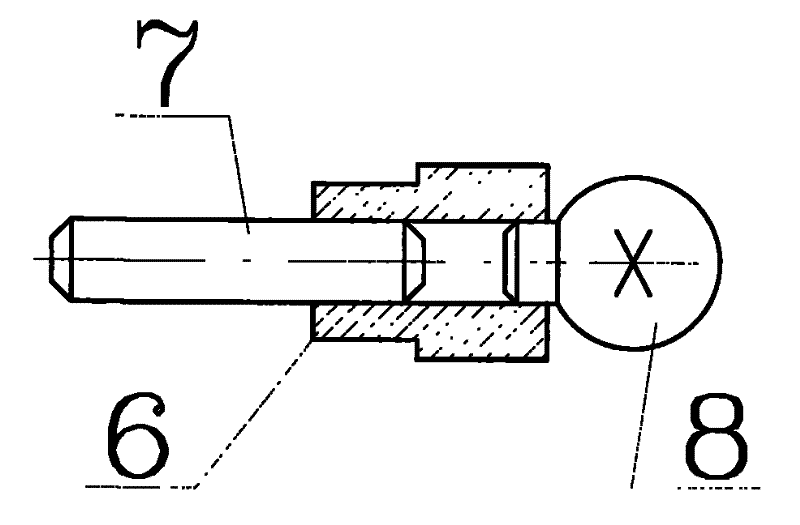

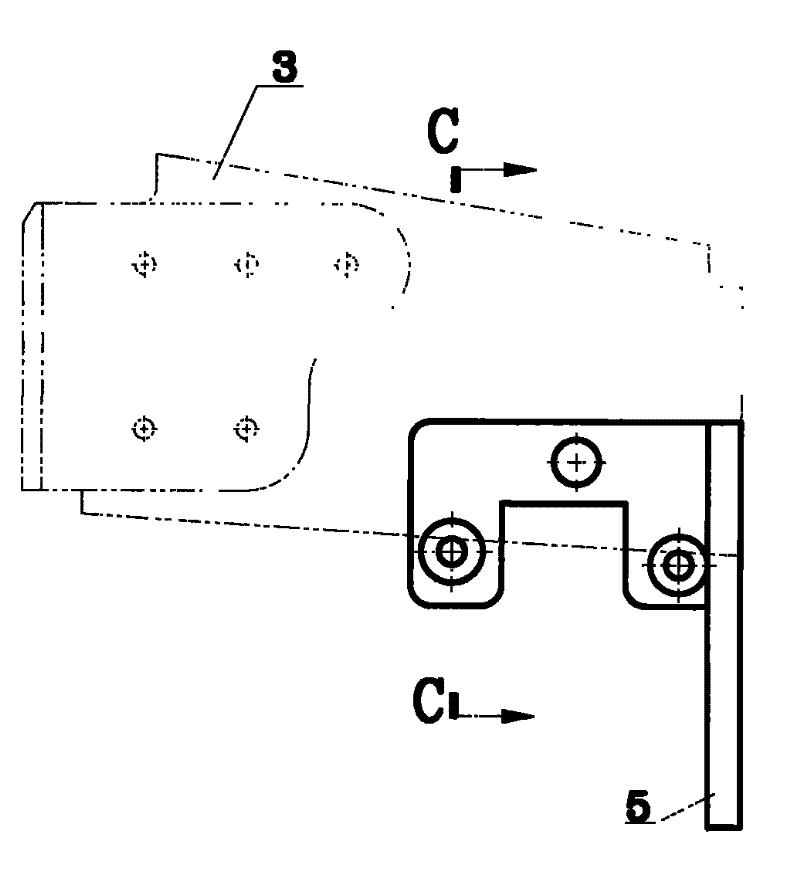

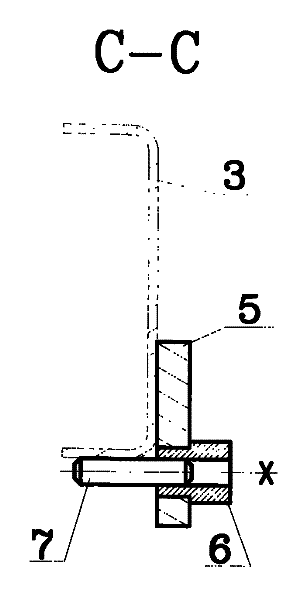

[0029] The present invention is further illustrated below by way of examples. In the following embodiments, the flexible positioning method for continuous positioning of the external surface of the workpiece proposed by the present invention is to select the external surface elements on the continuous positioning external surface of the workpiece - positioning points or lines, and the number of points and lines can be determined according to the workpiece external curvature. Changes are determined, and the shape positioning of the workpiece is determined by multi-point or multi-line; the continuous positioning of the contour surface is changed to intermittent point or line positioning; the selection and setting of the positioning points / lines are based on the above-mentioned selected positioning points or lines Place point contact or line contact locating pins with the shape of the workpiece—cylindrical pins of different sizes, and the shape locating pins (7) are distributed al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com