Measuring method of outer contour shape of metal part and detecting method of processing precision

A technology of metal parts and measurement methods, applied in metal processing equipment, metal processing machinery parts, point coordinate measurement, etc., can solve the problem of low measurement accuracy and achieve high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

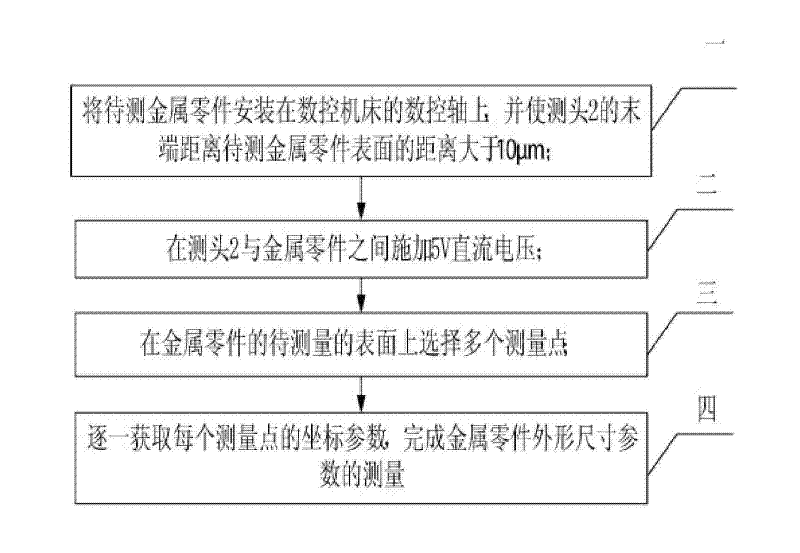

[0028] Specific embodiment one: a kind of method for measuring the outer contour shape of a metal part described in this embodiment, its specific steps are:

[0029] Step 1: Install the metal part to be tested on the CNC axis of the CNC machine tool, and make the distance between the end of the probe 2 and the surface of the metal part to be tested be greater than 10 μm;

[0030] Step 2: Apply a 5V DC voltage between the probe 2 and the metal part;

[0031] Step 3: Select multiple measurement points on the surface of the metal part to be measured;

[0032] Step 4: Obtain the coordinate parameters of each measurement point one by one, and complete the measurement of the external dimension parameters of the metal parts. The process of obtaining the coordinate parameters of each measurement point is:

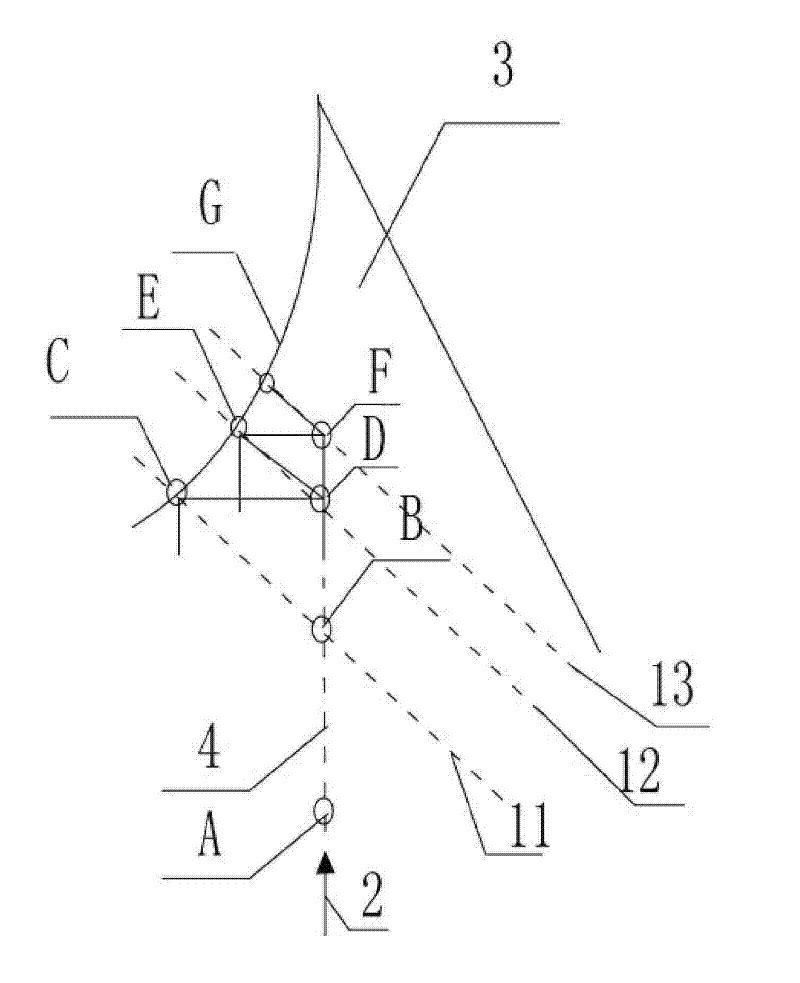

[0033] Step 41: move the measuring head 2 to the normal line, the normal line is the normal line of the surface where the point to be measured is located and passes through the po...

specific Embodiment approach 2

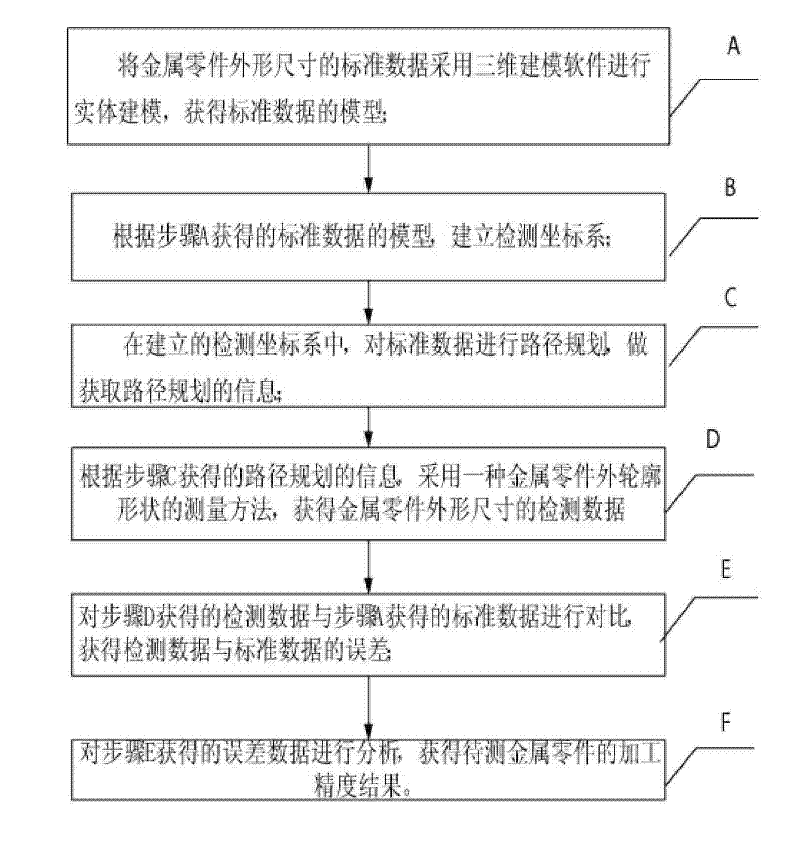

[0040] Specific embodiment two: the detection method of the machining accuracy of a kind of metal part described in this embodiment, its concrete steps are:

[0041] Step A: Use 3D modeling software to carry out solid modeling of the standard data of the external dimensions of the metal parts to obtain a model of the standard data;

[0042] Step B: Establish a detection coordinate system according to the model of the standard data obtained in step A;

[0043] Step C: In the established detection coordinate system, perform path planning on the standard data, and obtain path planning information;

[0044] Step D: According to the path planning information obtained in step C, a method for measuring the outer contour shape of the metal part of the present invention is used to obtain the detection data of the outer dimension of the metal part to be measured;

[0045] Step E: comparing the detection data obtained in step D with the standard data obtained in step A, and obtaining th...

example 1

[0052] Example 1: The nominal size required by a feature of the design part is 10mm, and the error range is between -0.1mm--+0.1mm; when the measured data is within the range of 9.9mm--10.1mm, the part is considered to be Qualified; when the measured data is between 9.8mm---10.2mm, it is considered to be out of tolerance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com