Polishing pad with abrasive grains and manufacturing method thereof

A manufacturing method and technology of abrasive grains, which are applied in the direction of manufacturing tools, abrasives, metal processing equipment, etc., can solve problems such as scratches, severe, large areas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0035] The manufacturing method of this example corresponds to the manufacturing method of the above-mentioned second embodiment. refer to Figure 6 , first, fiber raw material and a plurality of abrasive grains 32 are provided, and the abrasive grain 32 is added to the fiber raw material, wherein the fiber raw material comprises 75% by weight of polyethylene terephthalate and 40% by weight of polyethylene, the abrasive grain 32 is 3% by weight silica.

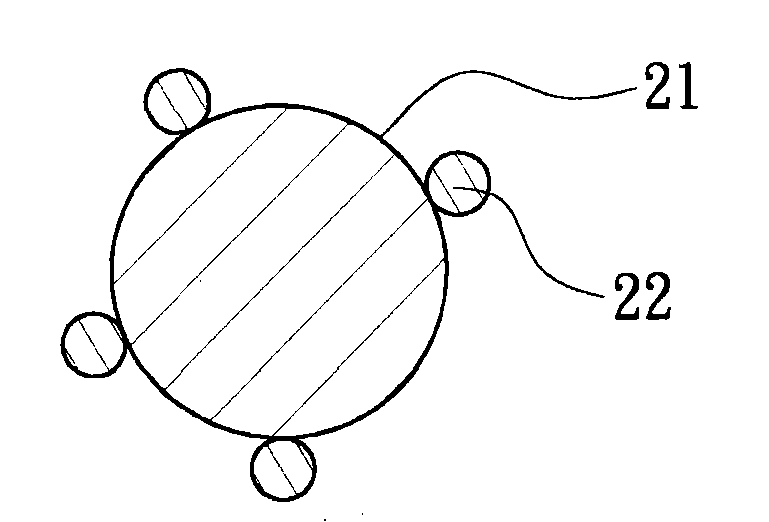

[0036] Next, a spinning step is performed to form the fiber raw material into a plurality of fibers 31 . Fiber 31 is solid, and part abrasive grain 32 is positioned at the inside of fiber 31, and part abrasive grain 32 is exposed on the surface of fiber 31 (as Figure 7 shown). The spinning step is melt spinning. First, the fiber raw material is melted at a temperature of 288°C through an extruder, sprayed out from a spinneret, and then cooled at a temperature of 22°C. The spinning speed is 550m / min. The raw silk is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com