Conveying device of roller body

A conveying device, roller body technology, used in transportation and packaging, winding strips, thin material handling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

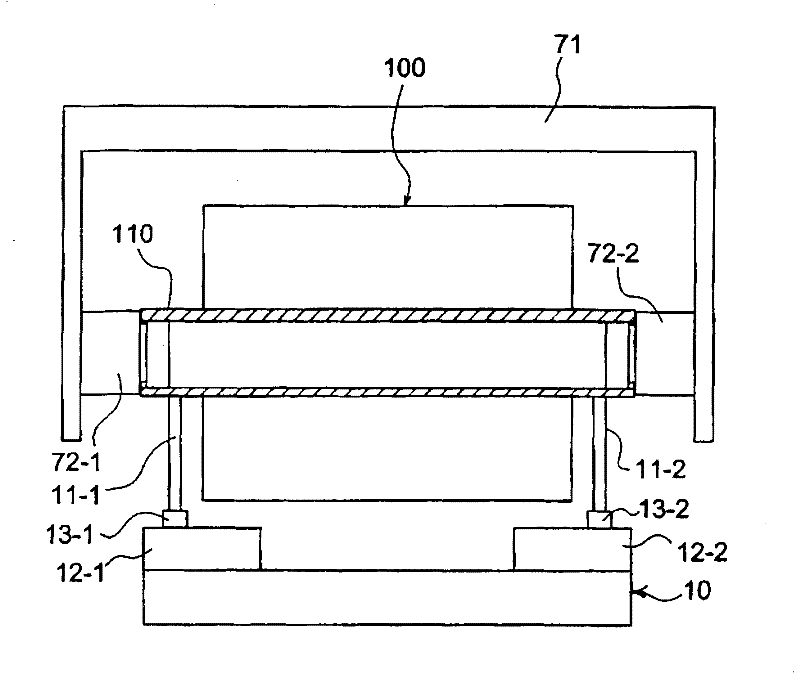

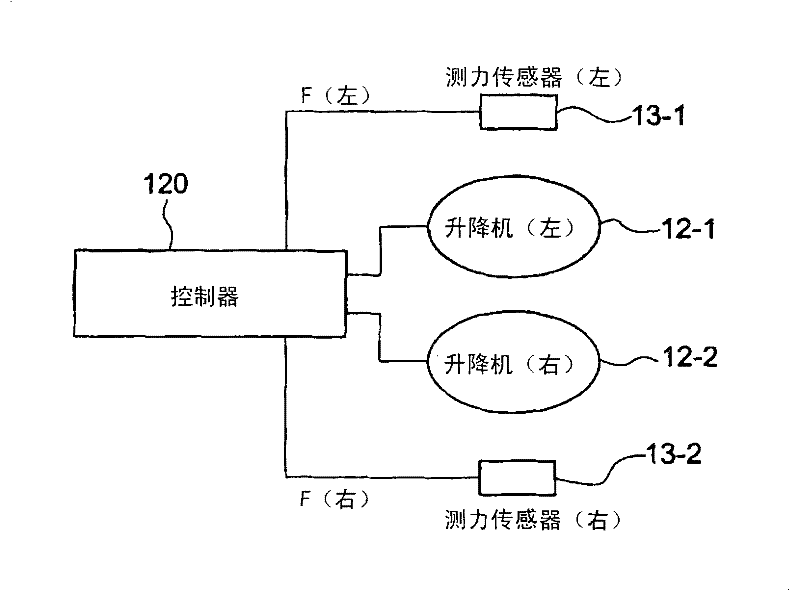

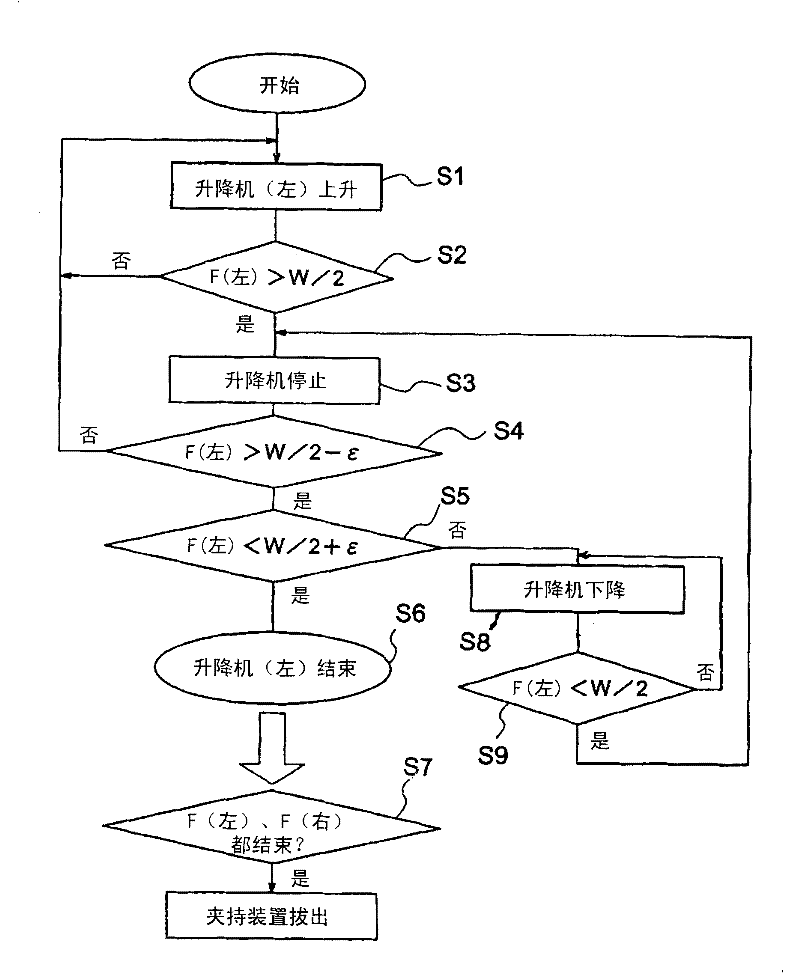

[0038] figure 1It shows the schematic structure of the roll conveying apparatus of this invention which has the transfer device for receiving the raw material roll grasped by a pair of clamping devices, figure 2 Represented by a block diagram figure 1 The structure of the control system of the transfer device shown.

[0039] exist figure 1 Only the schematic configuration of the transfer device 10 of the roller body transfer device is shown in . The two clamping devices that hold the raw material roll 100 in order to transfer it at the transfer site can be used with the Figure 7 The devices described in are the same, so detailed description is omitted, but in order to distinguish, the clamping device on the left side of the figure is given reference number 72-1, and the clamping device on the right side of the figure is given reference number 72-2. Furthermore, the transfer device 10 is usually mounted on a traveling unit having driving wheels and driven wheels, but si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com