Soft urethane foam with continuous air bubbles and preparation method thereof

A soft polyurethane and foam technology, which is applied in the field of soft polyurethane flat foam and its preparation, can solve the problems of low density, low foam resilience modulus, and low air permeability, and achieve high density, high air permeability, and high resilience modulus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

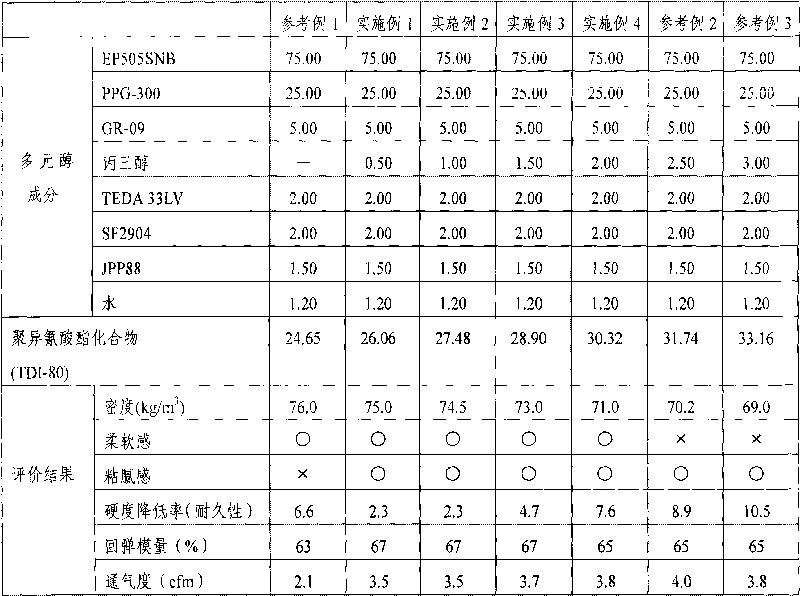

Examples

Embodiment

[0039]

[0040] 1) Polyether polyol compound

[0041] EP505SNB:

[0042] Ethylene oxide+propylene oxide copolymerized polyether polyol, EO=72% by weight, trifunctional, hydroxyl value=52 mgKOH / g (manufactured by Mitsui Chemicals Polyurethane Co., Ltd.)

[0043] PPG-3000:

[0044] Propylene oxide polymer polyether polyol, trifunctional, hydroxyl value=56 mgKOH / g (manufactured by Dow Chemical Company)

[0045] GR-09:

[0046] Trifunctional low molecular weight polyether polyol compound, hydroxyl value=400mgKOH / g (manufactured by Mitsui Chemicals Polyurethane Co., Ltd.)

[0047] 2) Catalyst: TEDA 33LV (manufactured by Tosoh Corporation)

[0048] 3) Cross-linking agent: glycerol

[0049] 4) JPP88: Antioxidant (manufactured by Seonghoku Chemical Co., Ltd.)

[0050] 5) Foaming agent: water

[0051] 6) Foam stabilizer: SF2904 (manufactured by Toray Dow Corning)

[0052] 7) Isocyanate component: TDI-80 (2,4-TDI / 2,6-TDI=80 / 20)

[0053]

[0054] According to the compounding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com