Method for weaving polyvinyl alcohol fiber lining cloth capable of dissolving in water at normal temperature

A polyvinyl alcohol fiber and water-soluble interlining technology, which is applied in non-woven fabrics, textiles, papermaking, embroidery machine mechanisms, etc., can solve the problems of embroidery product quality damage, poor dyeing fastness, and color fading of embroidery threads, so as to avoid Embroidery thread fading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

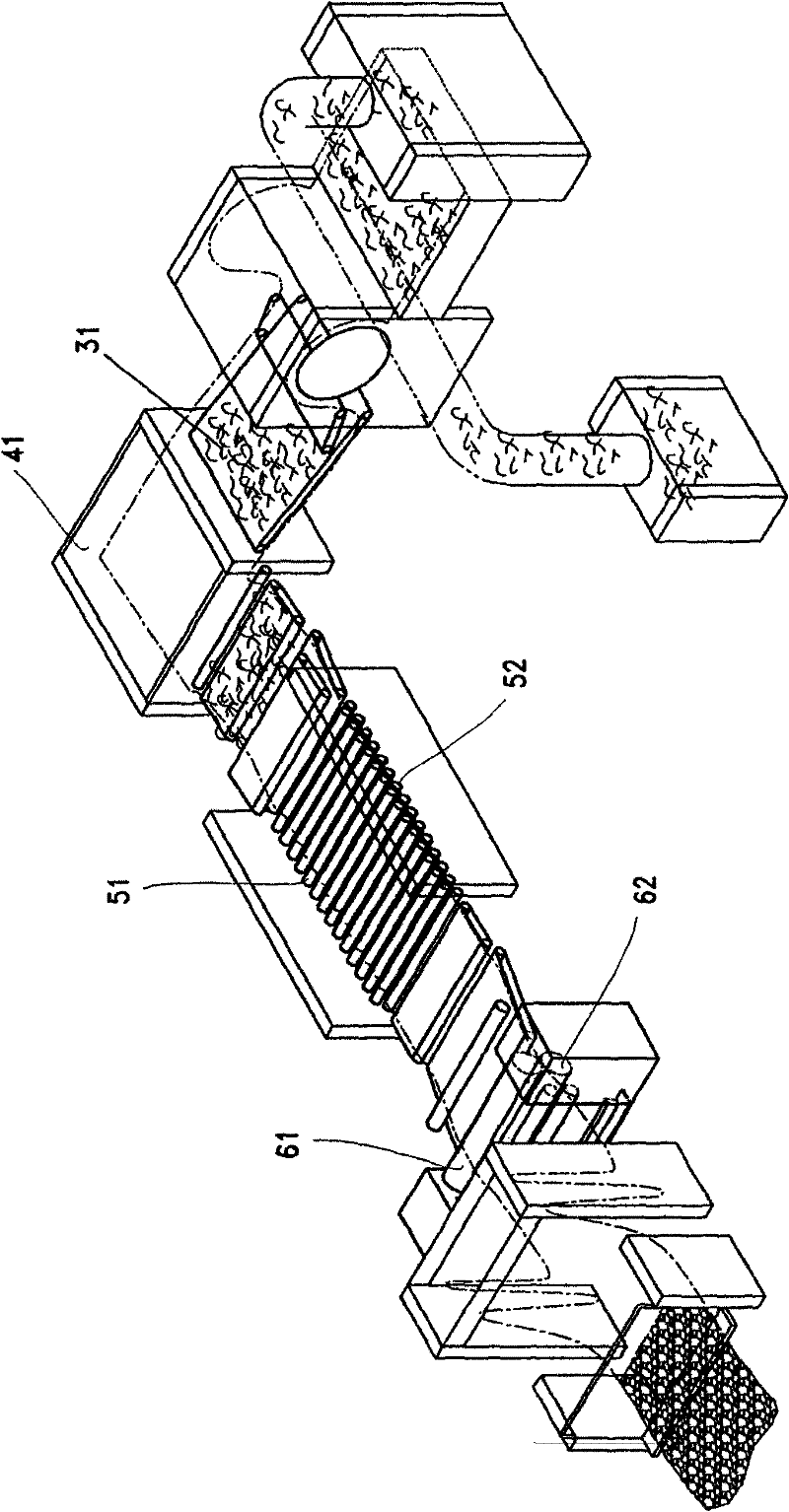

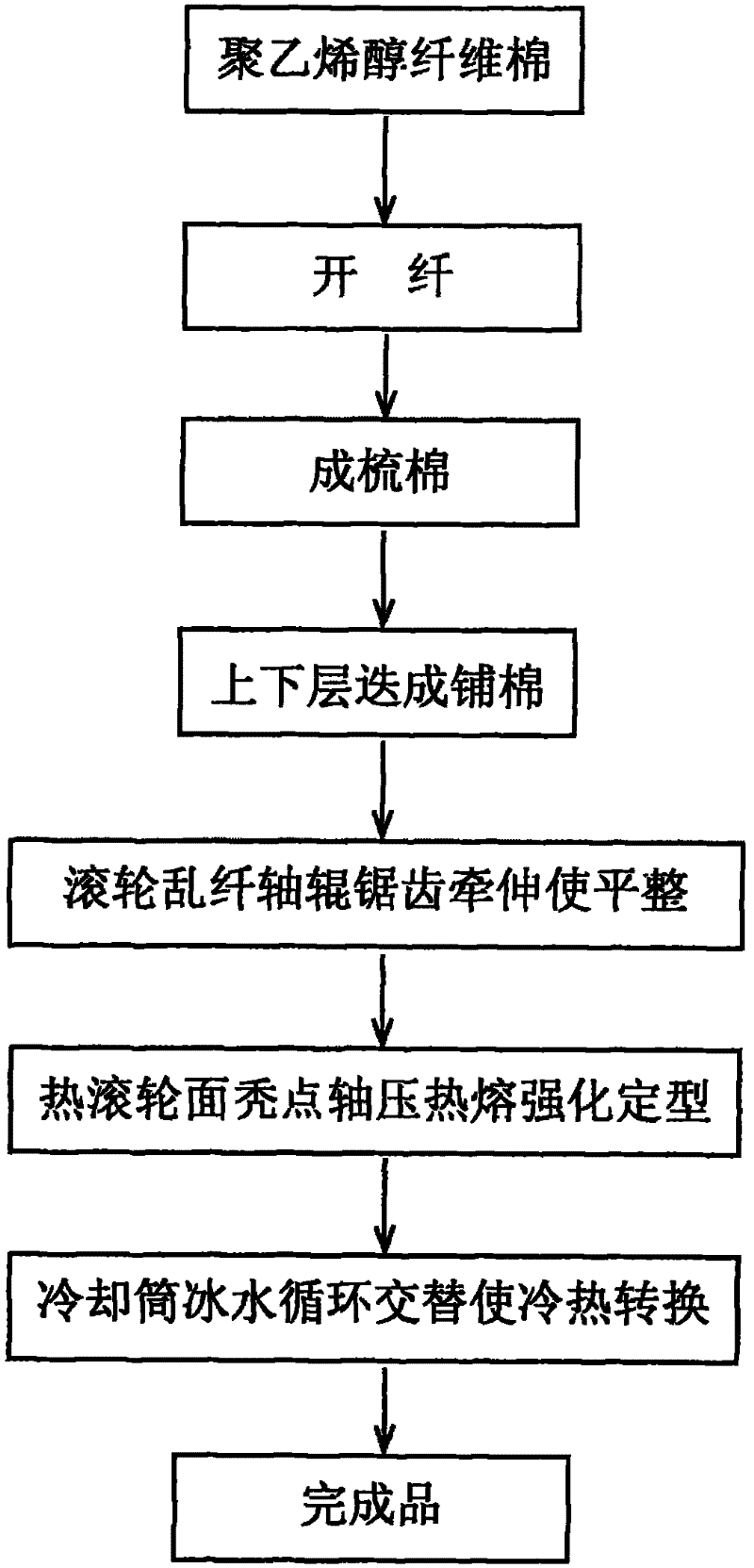

[0037] Such as Figure 1 to Figure 9 Shown, polyvinyl alcohol fiber cotton normal temperature water-soluble cloth weaving method of the present invention, its main manufacturing steps are as follows:

[0038] Polyvinyl alcohol fiber cotton input;

[0039] Stir the fiber cotton material to disperse;

[0040] Form fine line carding body for evenly distributed output;

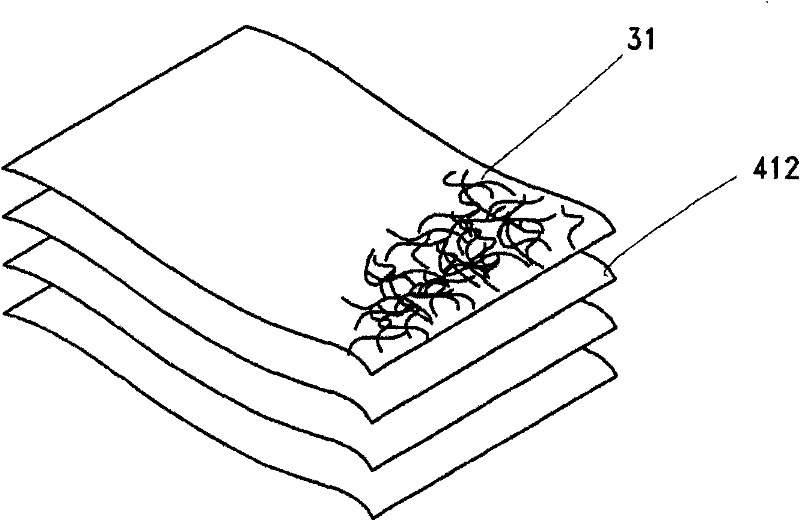

[0041] The carded yarn is laid into a mesh by overlapping the upper and lower layers, passing through the conveyor belt and entering the cotton laying machine in sequence;

[0042] The sawtooth arranged up and down to form the axial surface of the roller shaft is entrained and rolled into the shaft and roller, and at the same time, it is smoothed by means of the sawtooth spiral drafting cloth layer cotton;

[0043] Through the axial pressure and heat melting of the mesh set on the hot roller surface, it can be strengthened and shaped;

[0044] Use ice water circulation to alternately enter and exit the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com