Pier floating type composite anti-collision jacket

A composite material and floating technology, applied to roads, road safety devices, roads, etc., can solve the problems of high construction cost, poor impact buffer effect, sinking, etc., to delay the impact time and reduce the peak impact force , good energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

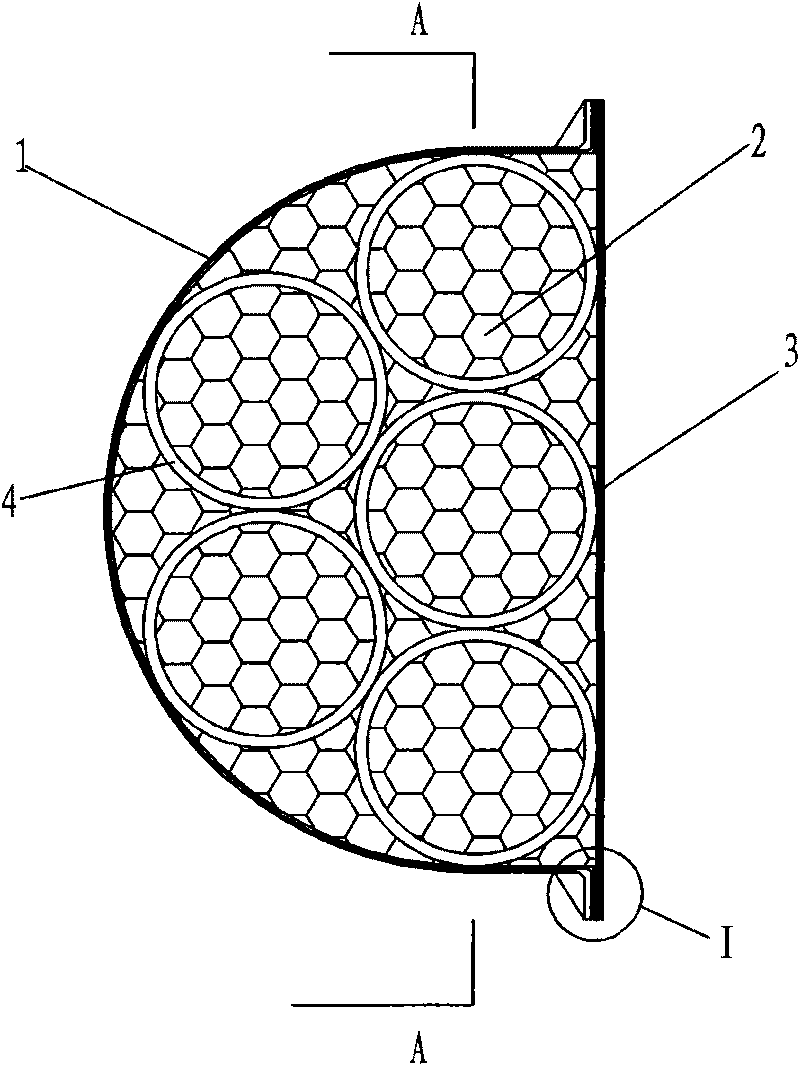

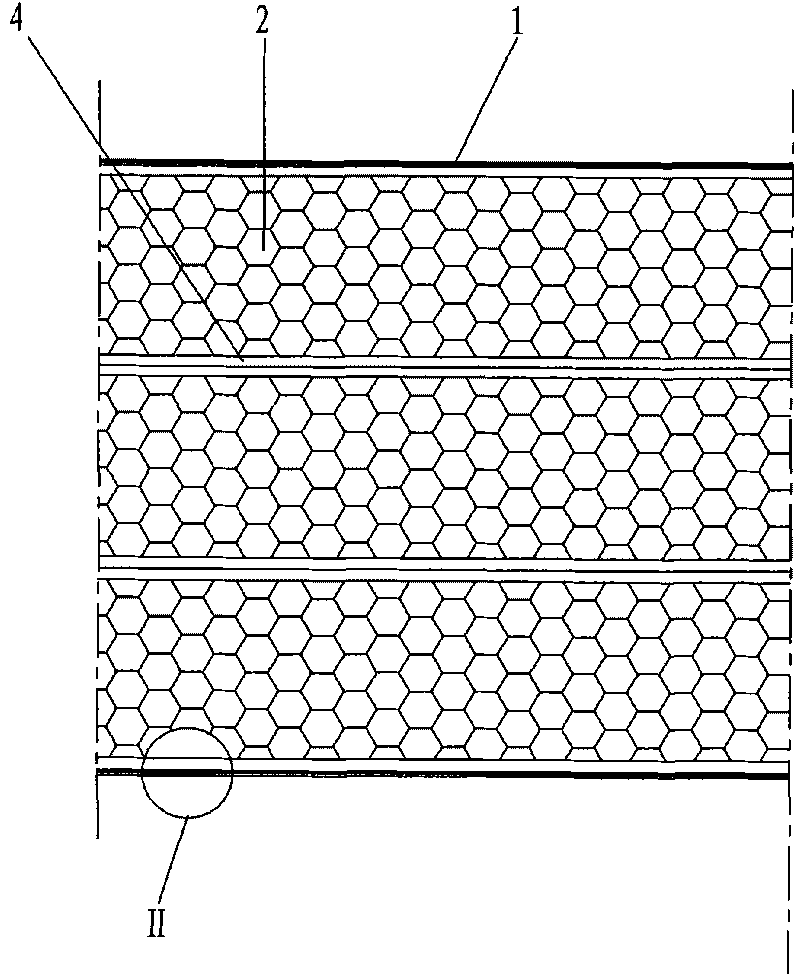

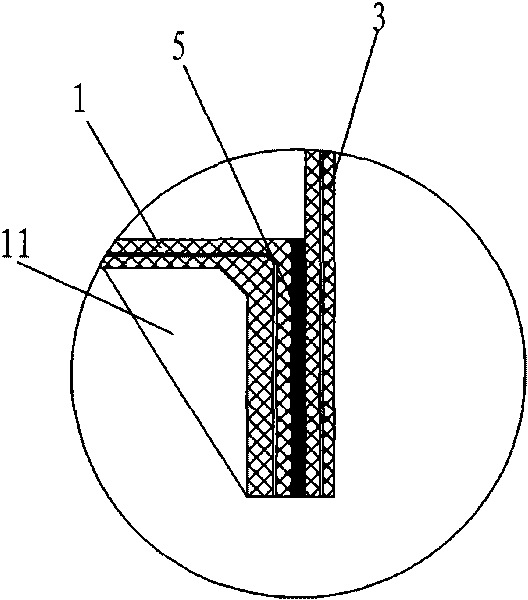

[0021] figure 1 It is a schematic diagram of a transverse cross-sectional structure of the present invention, figure 2 for figure 1 Sectional view along A-A direction, image 3 for figure 1 Enlarged view at I, Figure 4 for figure 2 Enlarged view at II, Figure 5 It is a structural schematic diagram of a cylindrical buffer body composed of a rubber traveler of the present invention, as shown in the figure: the pier floating composite anti-collision casing of the present invention includes a casing shell, and the casing casing is made of waterproof composite material; A cylindrical buffer body 4 bundled by rubber wire rings 41 is arranged along the longitudinal direction of the sleeve box. The longitudinal direction of the sleeve box refers to the direction around the pier; the cylindrical buffer bodies 4 are in contact with each other and fill the sleeve box. The shell and the casing are also filled with plastic foam 2 .

[0022] In this embodiment, the inner and oute...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap