Flexible connecting and sealing bitumastic impervious structure of tunnel deformation joint and constructing method

A technology of asphalt mastic and flexible connection, which is applied in tunnels, tunnel linings, underwater structures, etc., can solve the problems of anti-seepage technology and anti-seepage structure that are difficult to meet anti-seepage requirements, and achieve good hot-melt fluidity, Good bonding ability to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0037] The construction method of the deformation joint anti-seepage structure adopted in the present invention is carried out according to the following steps:

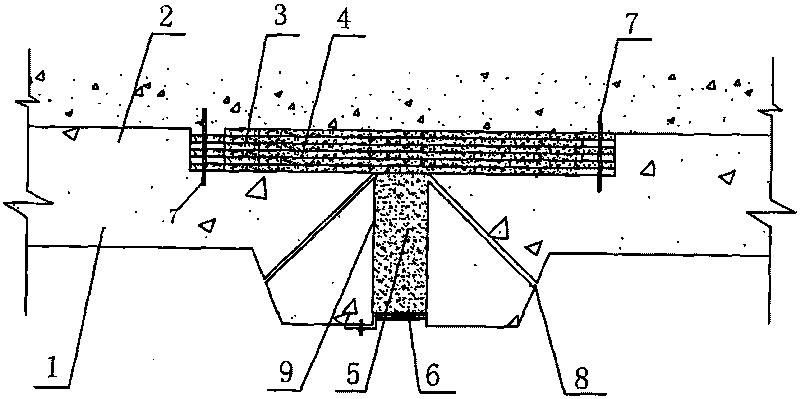

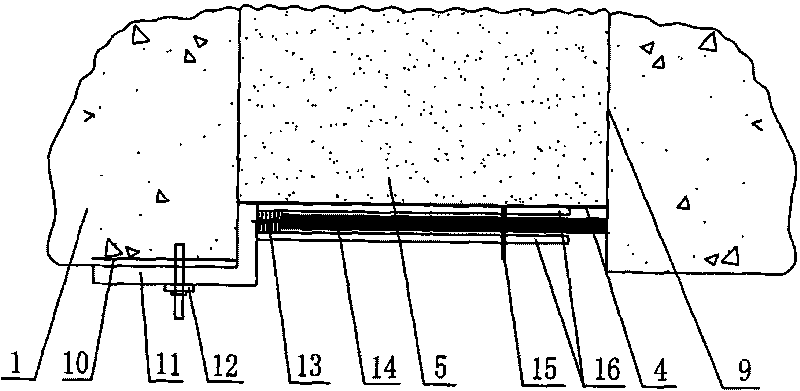

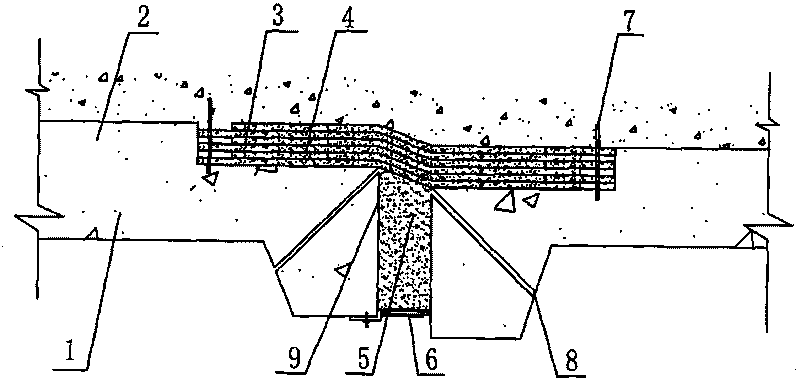

[0038] Step 1: Lay modified asphalt impervious board composite layer 3.

[0039] Such as figure 1 As shown, when the tunnel is excavated in the ground fissure section, the initial support lining 2 is first made, and then the inner surface of the initial support lining 2 is anchored at the position of the deformation joint 9 of the reinforced concrete lining. Layer 3 is on the inner wall of the initial support lining 2. The reserved width of the deformation joint 9 is 10cm~15cm. The adhesion layer of the anti-seepage board is formed by superimposing the SBS modified asphalt anti-seepage coil and the glass fiber mesh. The composite layer is about 10 It is composed of a bonding layer with a thickness of ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com