Z-shaped purline end part connecting process and method

A technology of end connection and purlin, which is applied in the field of Z-shaped purlin connection technology, can solve the problems of affecting the safety of the section and the uneven stress distribution of the lap joint, etc., and achieves convenient production, good economic benefits and popularization and use value, and the method is simple easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

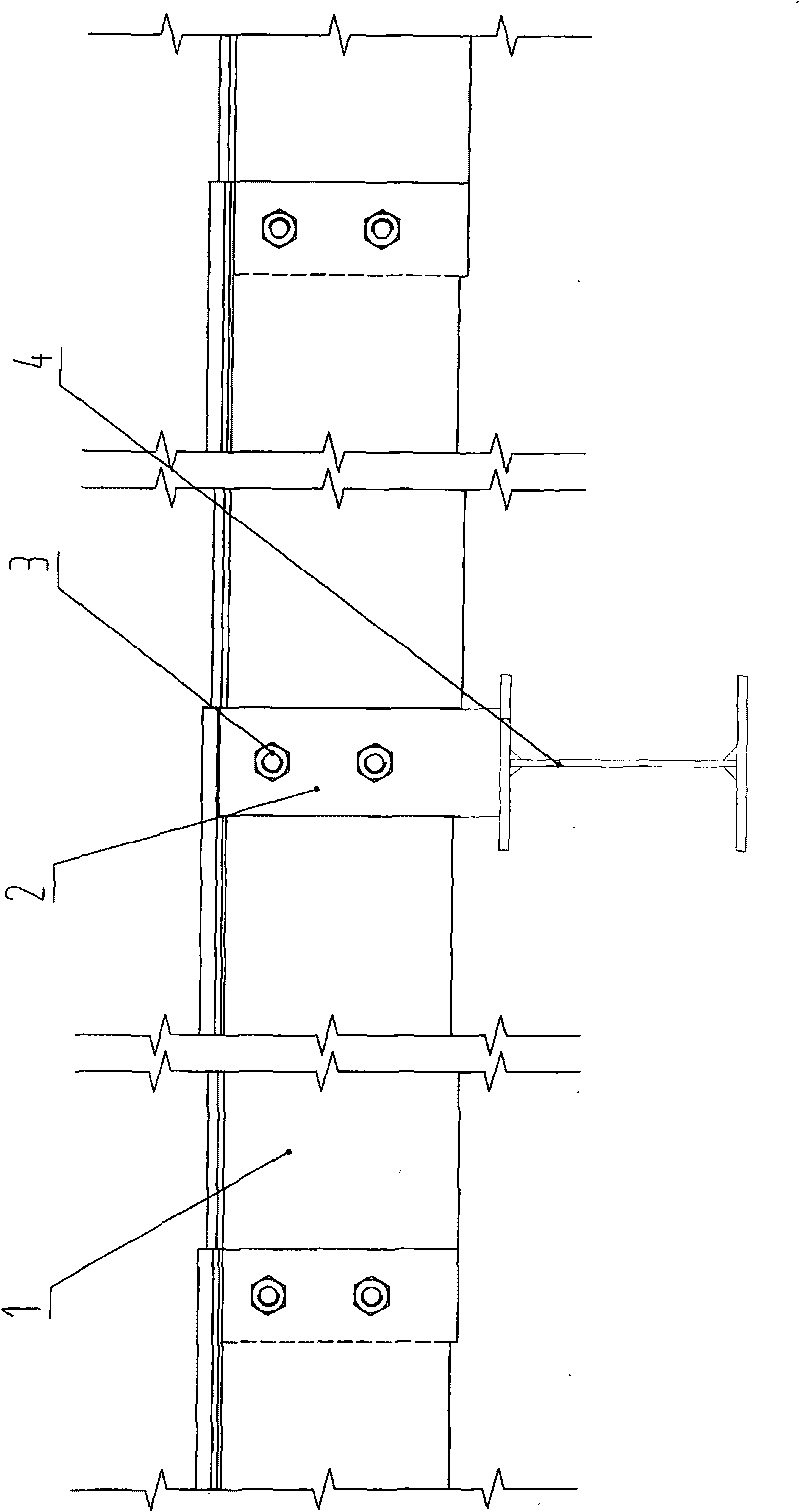

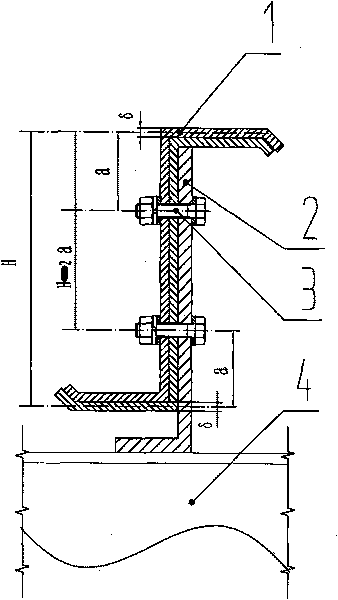

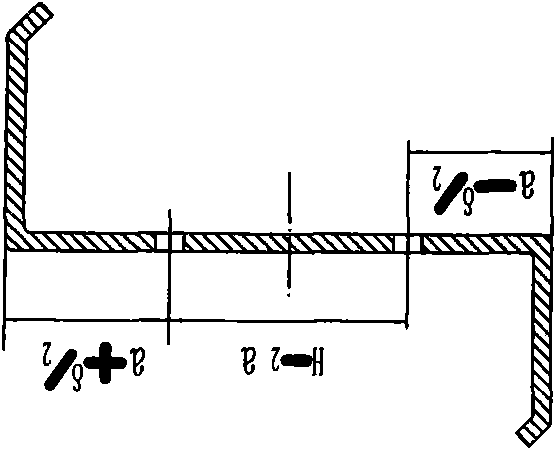

[0031] Such as figure 1 , 2 , shown in 3 and 4: a kind of technology and method of Z-type purlin end connection, is to lap together two purlin 1 ends to be connected one by one up and down, and the upper and lower rows of bolt holes are made at the lap joint, and then Fix the two purlins 1 and the purlin supporting plate 2 together with multiple sets of bolt fastening components 3, and the purlin supporting plate 2 is seated on the house beam 4; it is characterized in that: the described bolt holes are round holes, The bolt and the bolt hole are fit without clearance.

[0032] In order to achieve a clearance-free fit, the bolt hole manufacturing process is as follows:

[0033] 1) For the convenience of description, the following settings are made;

[0034] a), set the plate thickness of the Z-shaped purlin 1 as δ;

[0035] b), setting the centerline distance of the two horizontal plates on both sides of the Z-shaped purlin 1, the height of the purlin is H;

[0036] c), se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com