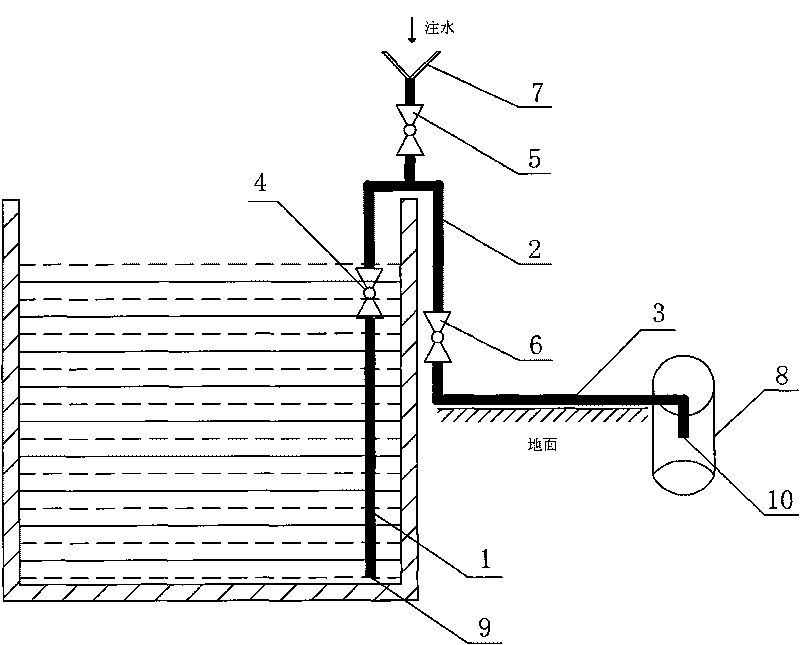

Automatic sewage disposal method of pool and sewage disposal system thereof

An automatic sewage and pool technology, applied in the waterway system, sewer system, water supply device, etc., can solve the problems of high investment and operation costs, pool leakage, large maintenance, etc., to save equipment investment, no power consumption, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Angang 1 # The water volume of the cooling tower pool of the 23500 oxygen generator circulating water system is 25200×13200×4000+15000×4000×3000mm, excluding the water stored in the pipeline and equipment heat exchanger, the water volume of the pool is 1510m 3 , circulating water volume 3900m 3 / h, is a relatively large industrial pool. Due to design mistakes, the drainage location is not appropriate, resulting in a large amount of supplementary water loss, and the water quality cannot be replaced.

[0026] The cold water tower pool is a reinforced concrete structure with a wall thickness of 500mm. Holes are drilled at the bottom of the pool as usual, which is particularly easy to damage the pool structure and cause pool leakage; the transformation must be carried out when the system is shut down, and the oxygen generator is always running. There is no opportunity and time for maintenance at all, and there is no suitable installation location even if the water pump is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com