Blow-down valve and disassembly-free filter

A sewage valve and valve core technology, which is applied to fixed filter element filters, filtration separation, valve devices, etc., can solve the problems of not installing a cleaning mechanism and a sewage valve at the same time, increasing the risk of leakage, complex structure, etc., and achieving a simple structure. , low cost, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

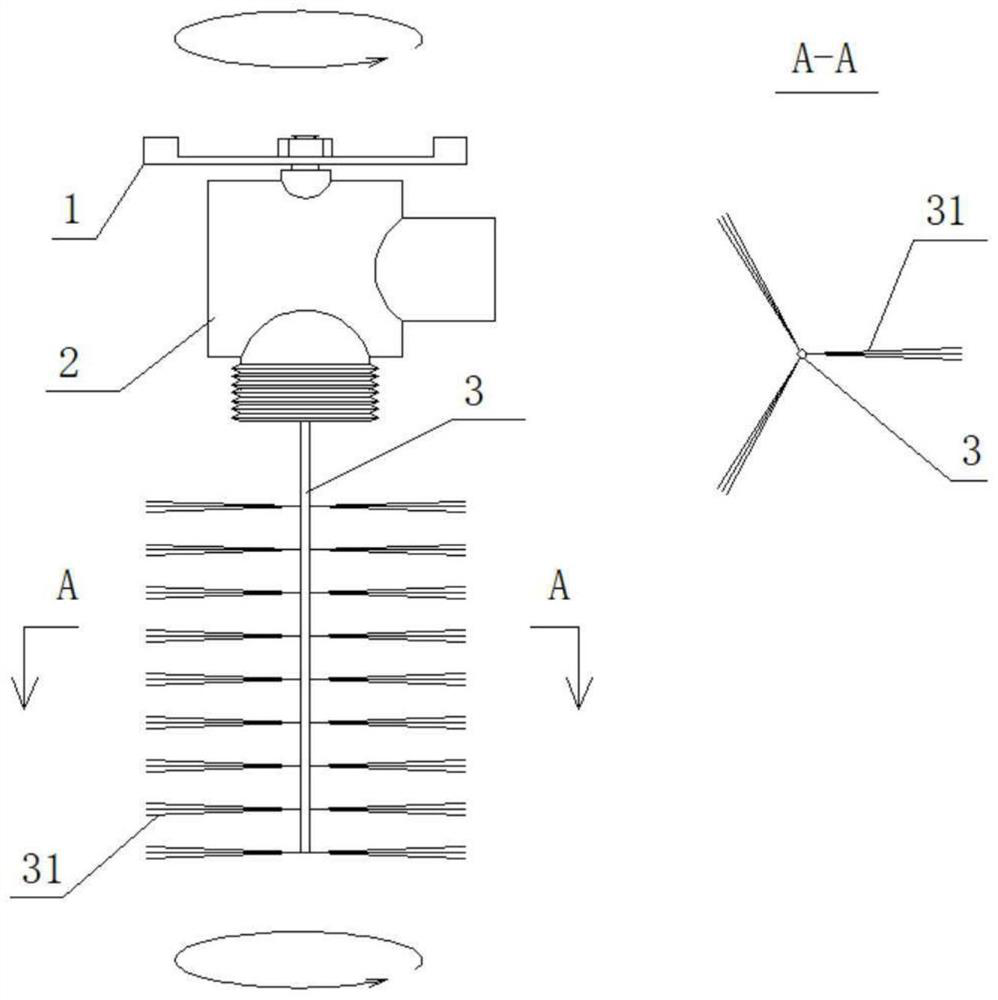

[0054] Embodiment 1: see figure 1 , Figure 4-5 , a blowdown valve, including a right-angle ball valve and a cleaning mechanism, the right-angle ball valve includes a valve body 2, a valve core gasket 21 and moving parts. The moving parts include a handle 1, a spool connecting rod 41, and a spool 4. One end of the spool connecting rod 41 is connected to the handle 1 outside the valve body, and the other end is connected to the spool 4, wherein the spool connecting rod 41, the spool 4 and the The inlet channel of the valve body 2 is coaxial, and the handle 1 drives the valve core 4 to rotate in the valve body 2 through the valve core connecting rod 41; the movement of the valve core 4 can make the outlet channel of the valve body 2 open and close.

[0055] The cleaning mechanism includes a brush rod 3 and a brush head 31, one end of the brush rod 3 is connected to the valve core 4 or the valve core connecting rod 41, and the other end extends to the outside of the valve body 2...

Embodiment 2

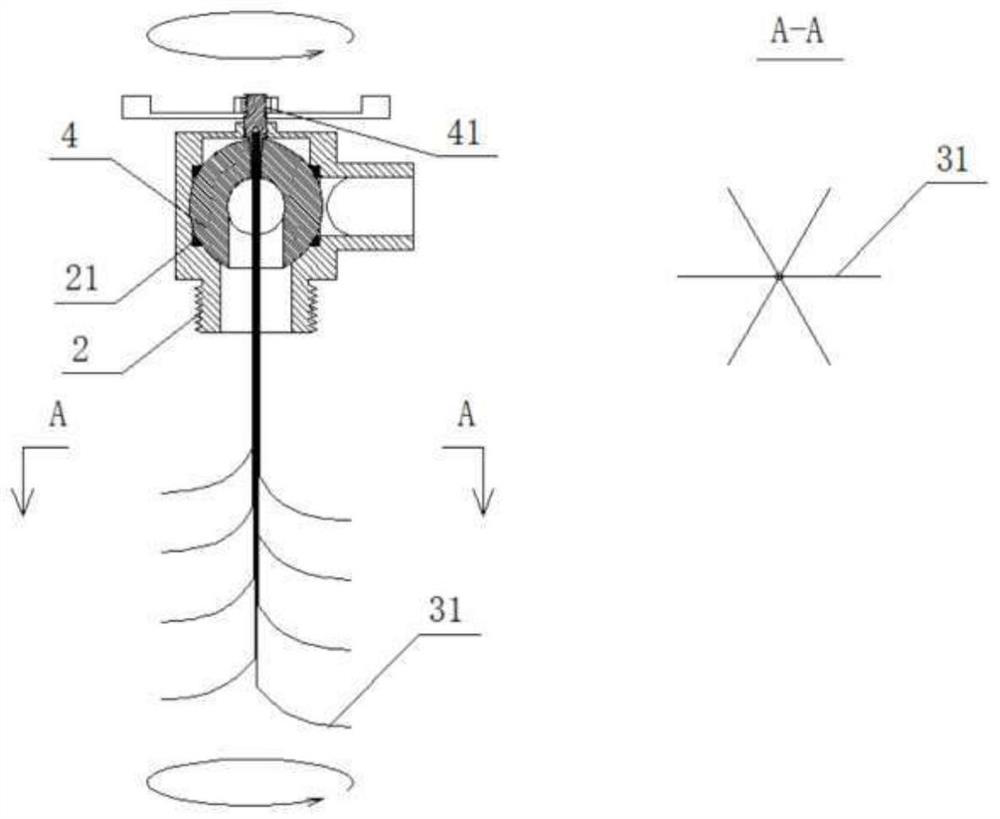

[0056] Embodiment 2: The difference with Embodiment 1 is that, see figure 2 , the cleaning mechanism adopts the curved elastic brush 31 with the brush rod and the brush head integrated, and the curved elastic brush 31 composed of several L-shaped steel wires gathers together at one end, and is connected with the valve core 4 or the valve core connecting rod 41. The other end spreads out to the outside of the valve body 2 . The other end of the elastic brush spreads out and contacts the inner wall of the barrel-shaped container to be cleaned.

Embodiment 3

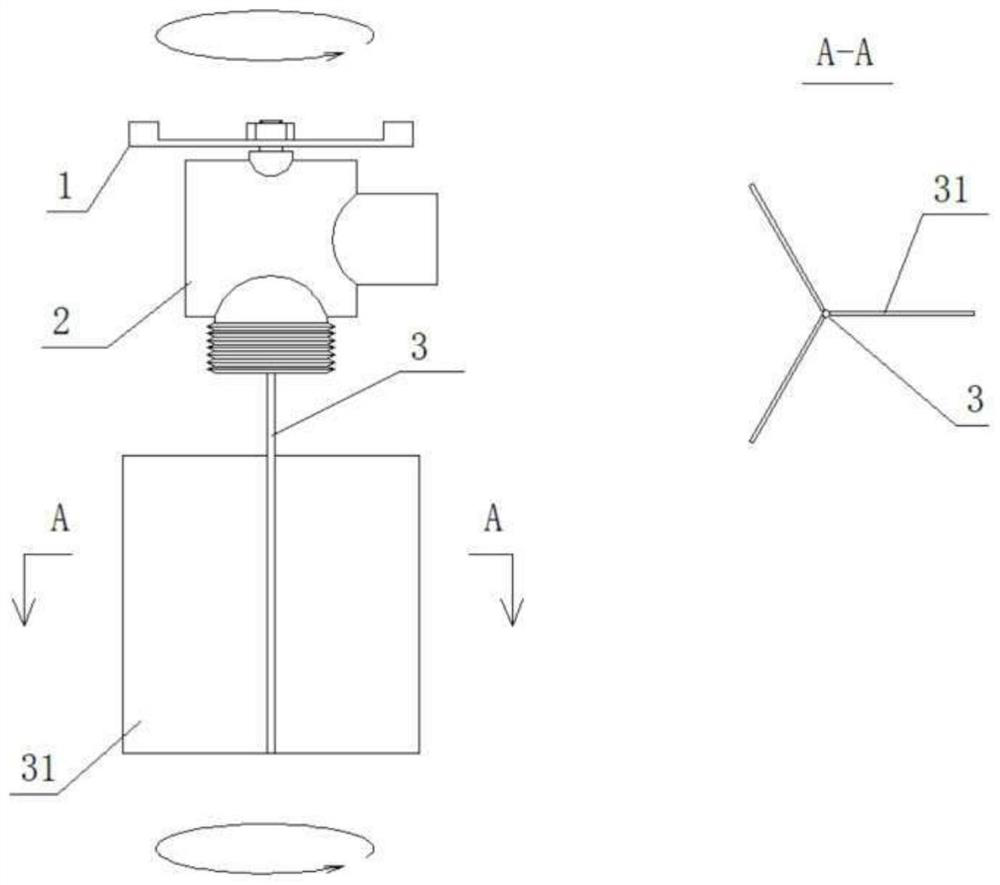

[0057] Embodiment 3: The difference with Embodiment 1 is that, see image 3 , The brush head 31 adopts a plate-shaped or shovel-shaped structure, such as a rubber or silicone scraper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com