Hydraulic cylinder device and hydraulic cylinder behavior control system with same

A control system and hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve the problems of unfavorable intelligent controller data processing and computing capabilities and coordination control capabilities, inability to detect the piston of the main cylinder in real time, and hydraulic oil flow requirements, etc., to achieve powerful data processing Computing ability and coordination control ability, low cost, and the effect of optimizing the performance of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

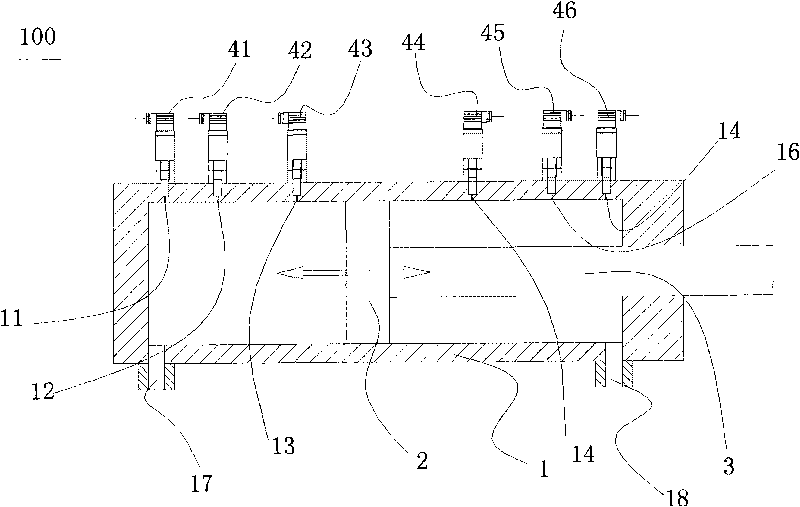

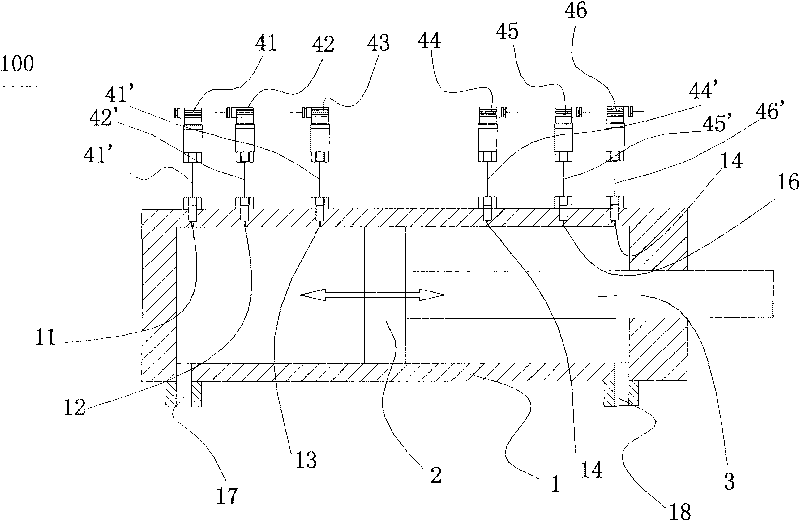

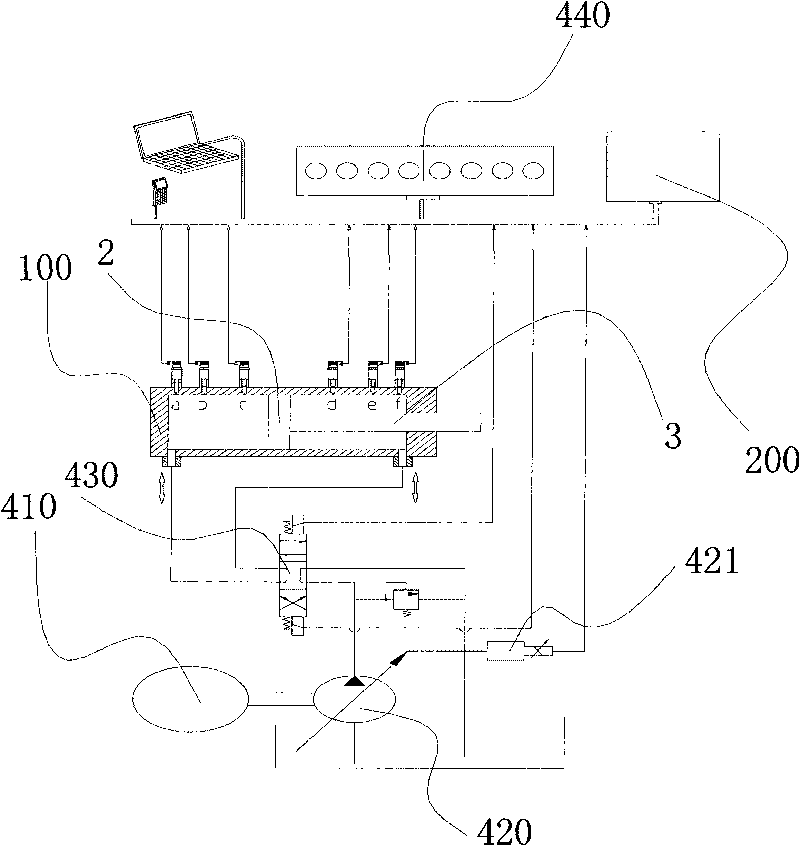

[0027] The present invention provides a hydraulic cylinder device 100, which includes a cylinder body 1, a piston 2 moving in the cylinder body 1, and a piston rod 3 with one end connected to the piston 2 and the other end extending out of the cylinder body 1. In order to precisely control the delivery speed, motion acceleration and reversing of the piston 2, a plurality of signal through holes arranged along the longitudinal direction of the cylinder 1 can be formed on the cylinder wall of the cylinder 1 to divide the piston stroke into multiple stroke segments. , meanwhile, the hydraulic cylinder device 100 of the present invention further includes a plurality of pressure sensors corresponding to the plurality of signal through holes.

[0028] figure 1 It is a schematic cross-sectional view of the first preferred embodiment of the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com