Embedded burner

A burner and embedded technology, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of excessive gas, reactive power loss, unreasonable matching, etc., and achieve the effect of improving gas efficiency and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

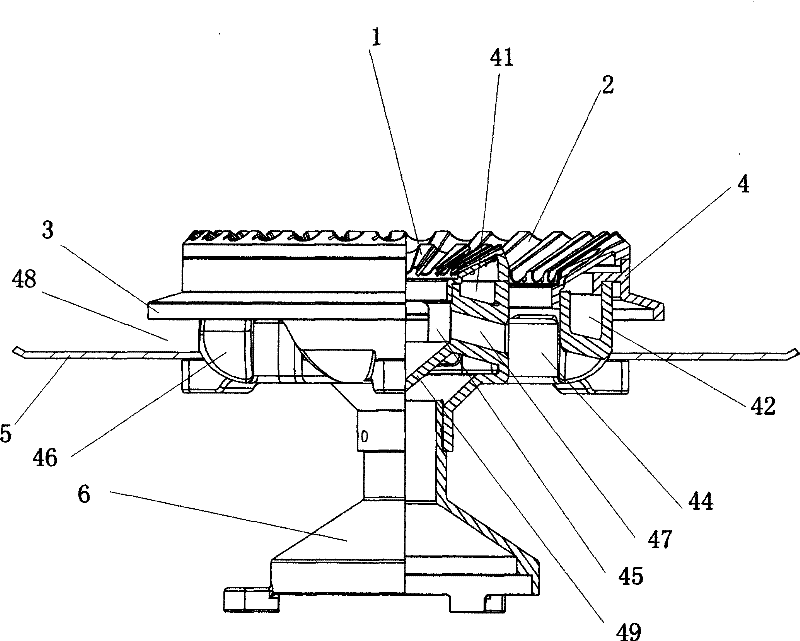

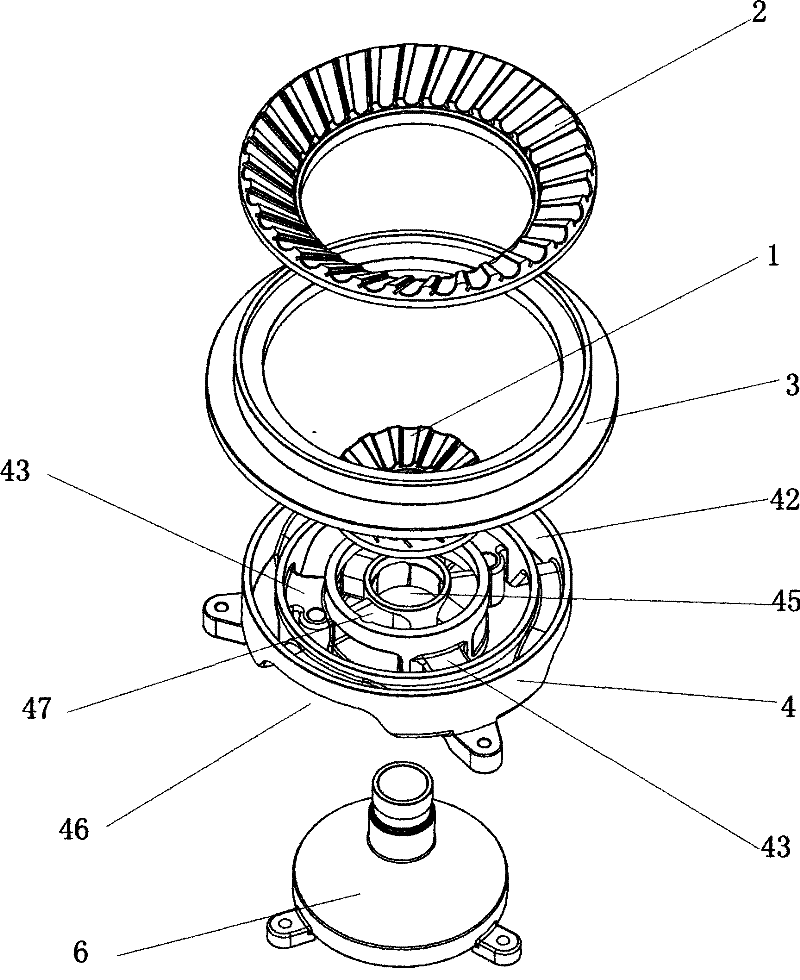

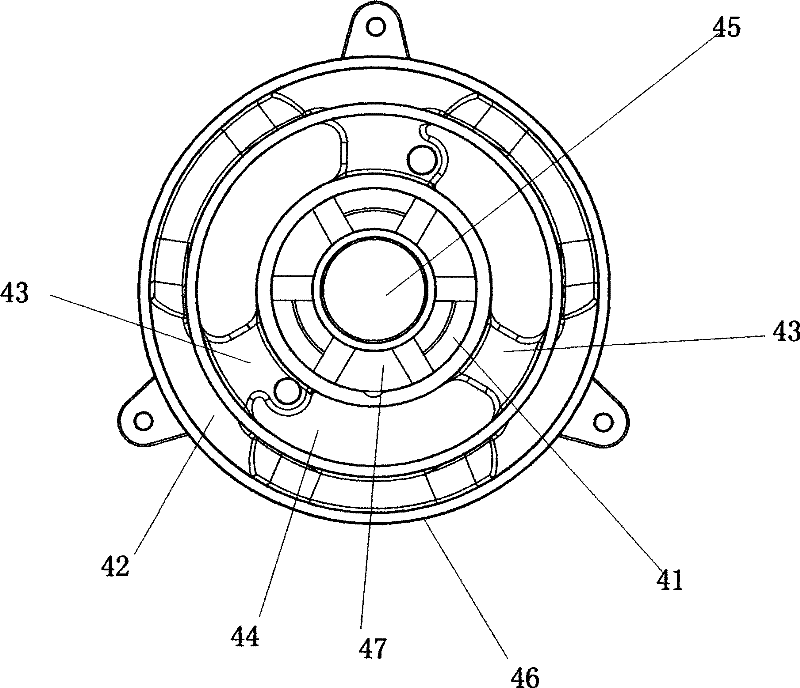

[0013] The present invention as figure 1 , figure 2 , image 3 As shown, an embedded burner includes an inner fire cover 1, an outer fire cover 2, a cover ring 3, a gas seat 4, a water tray 5 and an air mixing pipe 6 with a swirl structure, and the gas seat 4 is provided with a positive To inner and outer fire cover 1, the inner ring gas groove 41, the outer ring gas groove 42 of 2, be provided with several gas passages 43 that make the two communicate between the inner and outer ring gas grooves 41 and 42, in each phase An open outer air mixing area 44 is provided between adjacent gas passages 43, an inner air mixing area 45 with a closed bottom is provided at the center of the gas seat 4, and an air mixing area 45 communicating with the outer air mixing area 44 is provided on the outer edge of the gas seat 4. The tuyere 46 is provided with an air mixing channel 47 between the outer air mixing area 44 and the inner air mixing area 45 , and an air guide groove 48 is reserve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com