High-elasticity flame-retardant two-component wall surface material and preparation method thereof

A two-component, high-elasticity technology, applied in the field of mine ventilation, can solve the problems of wall cracking of ventilation structures, high cost of spraying materials, and increased air leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

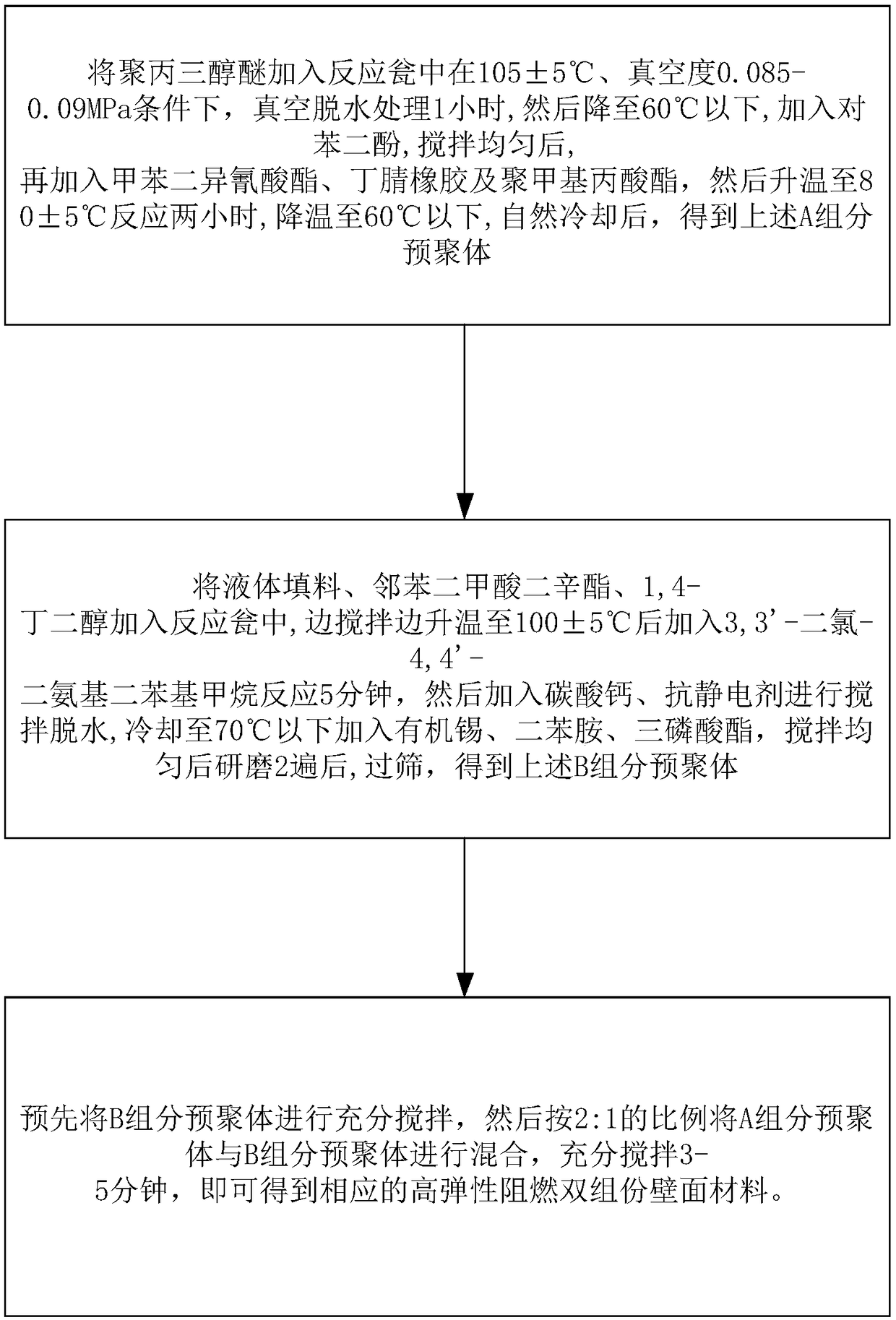

[0029] The present invention also provides a method for preparing the above-mentioned highly elastic flame-retardant two-component wall surface material, which includes the following steps:

[0030] A. Add the polyglycerol ether into the reaction vat, under the conditions of 105±5°C and vacuum degree of 0.085-0.09MPa, vacuum dehydration treatment for 1 hour, then lower it to below 60°C, add hydroquinone, stir evenly, and then Add toluene diisocyanate, nitrile rubber and polymethylpropionate, then raise the temperature to 80±5°C for two hours, cool down to below 60°C, and cool naturally to obtain the above-mentioned component A prepolymer;

[0031] B. Add liquid filler, dioctyl phthalate, and 1,4-butanediol into the reaction vat, heat up to 100±5°C while stirring, then add 3,3'-dichloro-4,4'- Diaminodiphenylmethane was reacted for 5 minutes, then calcium carbonate and antistatic agent were added for stirring and dehydration, and organic tin, diphenylamine and triphosphate were ...

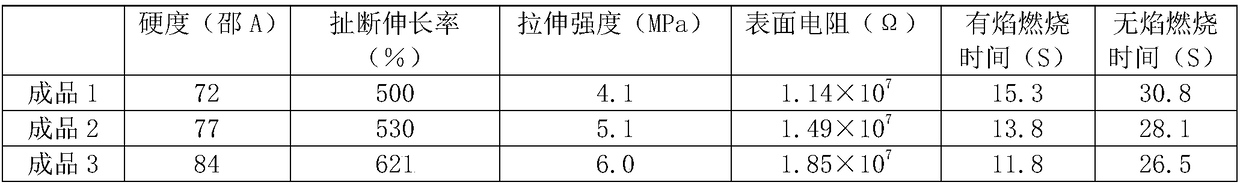

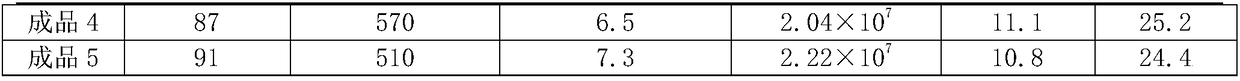

Embodiment 1

[0035] According to parts by weight, it is made of the following raw materials by weight. The prepolymer of component A includes 700 parts of polyglycerol ether, 1.06 parts of hydroquinone, 90 parts of toluene diisocyanate, 100 parts of nitrile rubber, and polymethylpropionic acid 50 parts of ester; B component prepolymer including 650 parts of liquid filler, 20 parts of octyl phthalate, 30 parts of 1,4-butanediol, 3,3'-dichloro-4,4'-diamino 10 parts of diphenylmethane, 250 parts of calcium carbonate, 3.08 parts of antistatic agent, 1.03 parts of organic tin catalyst, 4.08 parts of diphenylamine, and 5.12 parts of triphosphate.

[0036] To obtain the above-mentioned highly elastic flame-retardant two-component wall material, the specific steps are:

[0037]Step 1: Add polyglycerol ether into the reaction vat at 105±5°C, vacuum degree 0.085-0.09MPa, vacuum dehydration for 1 hour, then drop below 60°C, add hydroquinone, stir evenly, Then add toluene diisocyanate, nitrile rubber...

Embodiment 2

[0041] According to parts by weight, it is made of the following raw materials by weight. The prepolymer of component A includes 750 parts of polyglycerol ether, 1.24 parts of hydroquinone, 81 parts of toluene diisocyanate, 82 parts of nitrile rubber, and polymethylpropionic acid 65 parts of ester; B-component prepolymer including 700 parts of liquid filler, 16.17 parts of octyl phthalate, 42 parts of 1,4-butanediol, 3,3'-dichloro-4,4'-diamino 12.12 parts of diphenylmethane, 214 parts of calcium carbonate, 5.06 parts of antistatic agent, 1.72 parts of organotin catalyst, 5.02 parts of diphenylamine, and 6.24 parts of triphosphate.

[0042] To obtain the above-mentioned highly elastic flame-retardant two-component wall material, the specific steps are:

[0043] Step 1: Add polyglycerol ether into the reaction vat at 105±5°C, vacuum degree 0.085-0.09MPa, vacuum dehydration for 1 hour, then drop below 60°C, add hydroquinone, stir evenly, Then add toluene diisocyanate, nitrile ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com