Probe servo mechanism for eddy current inspection of main bolt inspection machine of nuclear pressure vessel

A nuclear pressure vessel and follower mechanism technology, which is applied in nuclear engineering, nuclear power generation, nuclear reactor monitoring, etc., can solve the problems of lack of technology and inspection equipment, and achieve automatic inspection of stable structure, no swing, and stable detection signal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

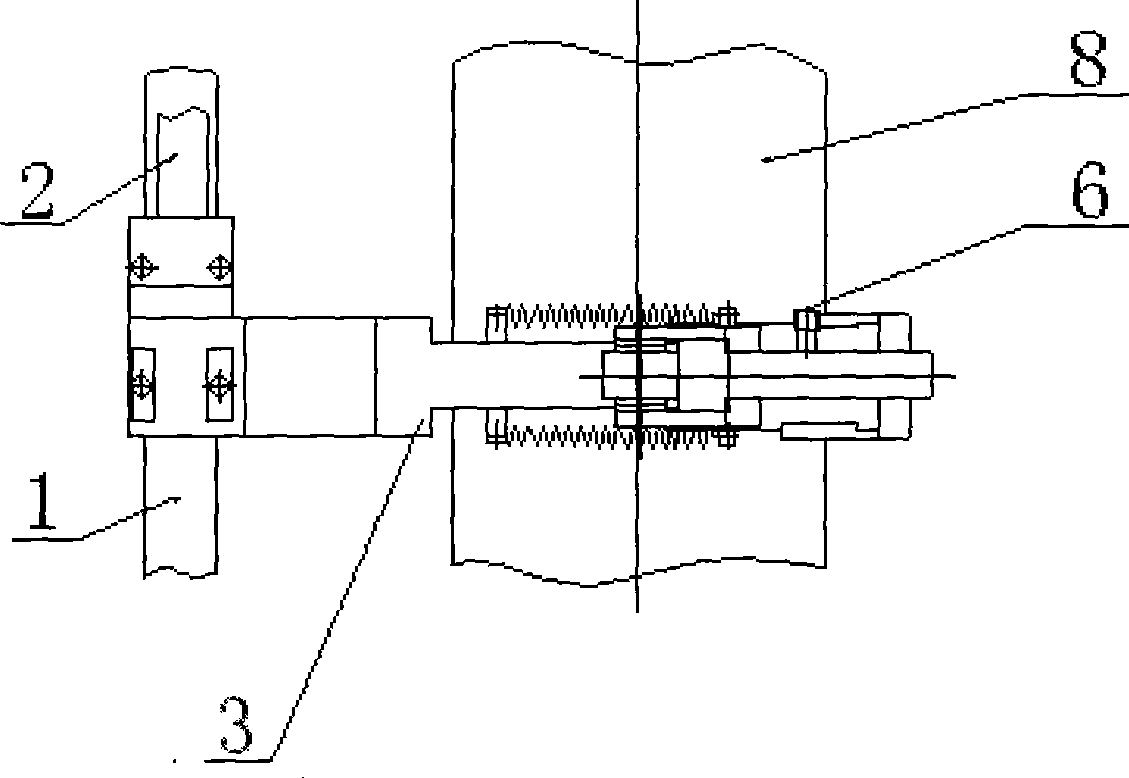

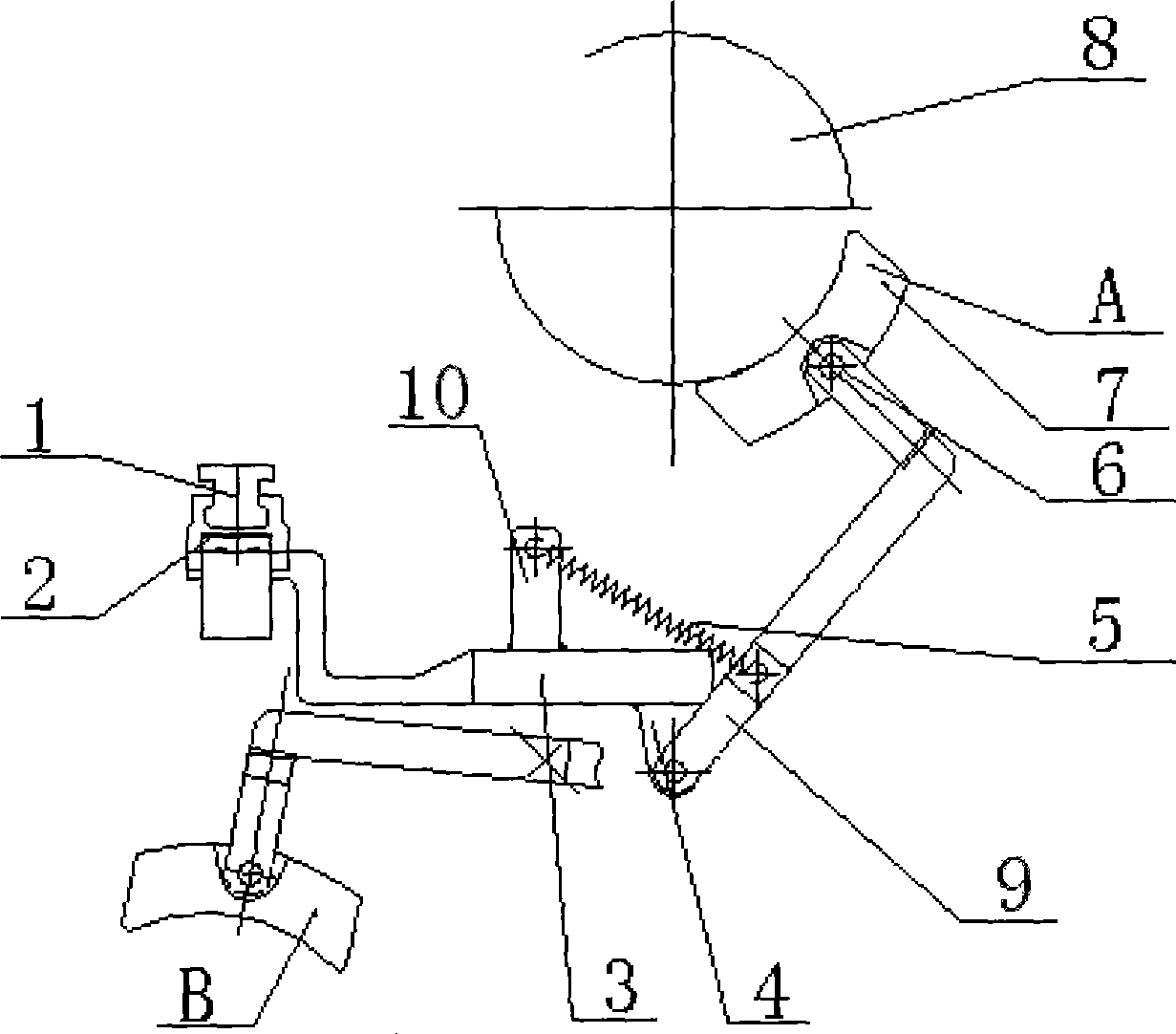

[0015] A nuclear pressure vessel main bolt inspection machine eddy current inspection probe follower mechanism, such as figure 1 and 2 shown. One end of the turning seat 3 has a vertical bend, and one end of the turning seat 3 is stuck on the upright linear rail 1 through a card slot, and can slide up and down along it, and the upper end is connected with a constant force sheet spring 2, and the turning seat 3 A rectangular block 10 is welded in the middle of the other end for connecting the spring 5, and a support 4 is welded at the extreme end of the flip seat 3, and its protruding direction is opposite to the protruding direction of the rectangular block 10; the pressing rod 9 is "L" Shaped structure, both ends of which are processed with "U"-shaped grooves, the support 4 at the end of the flip seat 3 is stuck in the "U"-shaped groove of the pressing rod 4, and fixed by a cylindrical pin 6; in the rectangular block One end of the spring 5 is connected to the end of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com