System for irradiation processing high-energy electron beam having self-shielding radiation source

A high-energy electron beam and processing system technology, applied in the field of electron beam irradiation processing, can solve the problems of reducing system power efficiency, increasing construction cost, occupation, etc., and achieve the effect of saving construction cost and facilitating installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

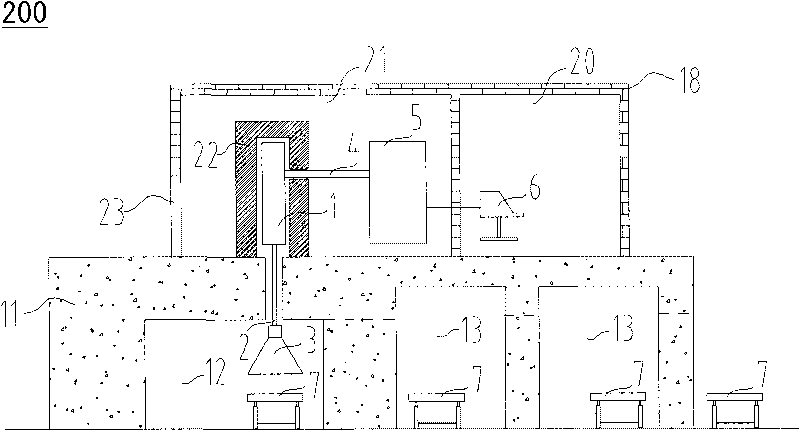

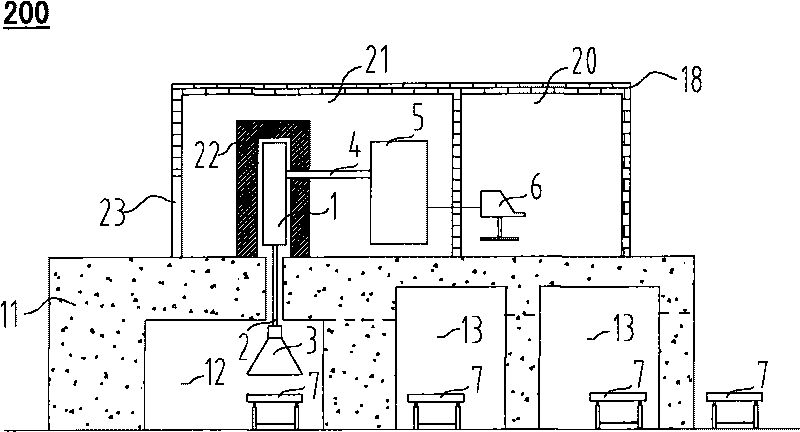

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

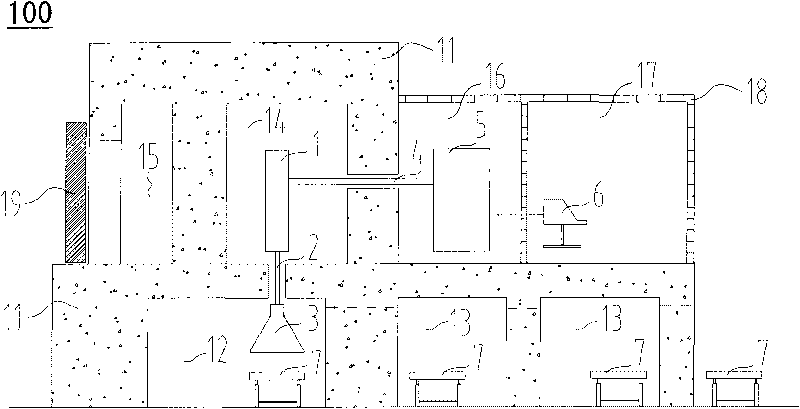

[0013] refer to figure 2 , which shows a radiation self-shielding high energy electron beam irradiation processing system 200 according to an embodiment of the present invention. The high-energy electron beam irradiation processing system 200 is arranged in upper and lower layers.

[0014] The upper level includes the accelerator room 21 and the control room 20 , which are constructed of ordinary masonry 18 . The door 23 of the accelerator room 21 is an ordinary light door without radiation protection function, rather than a very thick and heavy shield door as required in the prior art. The accelerator 1 is installed inside the accelerator chamber 21 . A shielding body 22 is installed on the outside of the accelerator 1 , including its periphery and top. The shielding body 22 is made of heavy metal materials such as steel, lead or tungsten, has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com