BMS demarcating module based on CCP protocol

A protocol, CAN bus technology, applied in the field of calibration module design, can solve the problems of slow communication speed, unsatisfactory effect, low real-time performance, etc., to improve performance, improve portability and versatility, and shorten development cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

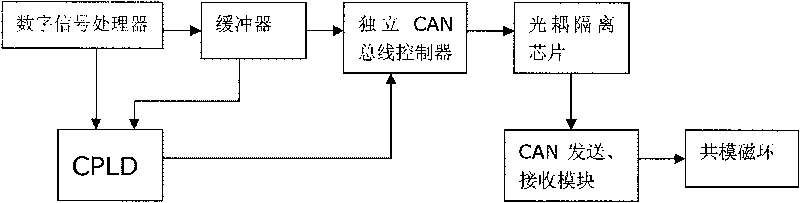

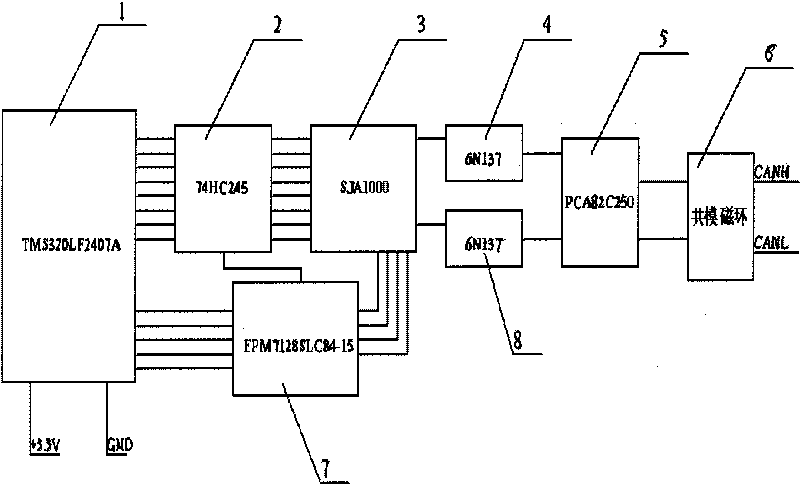

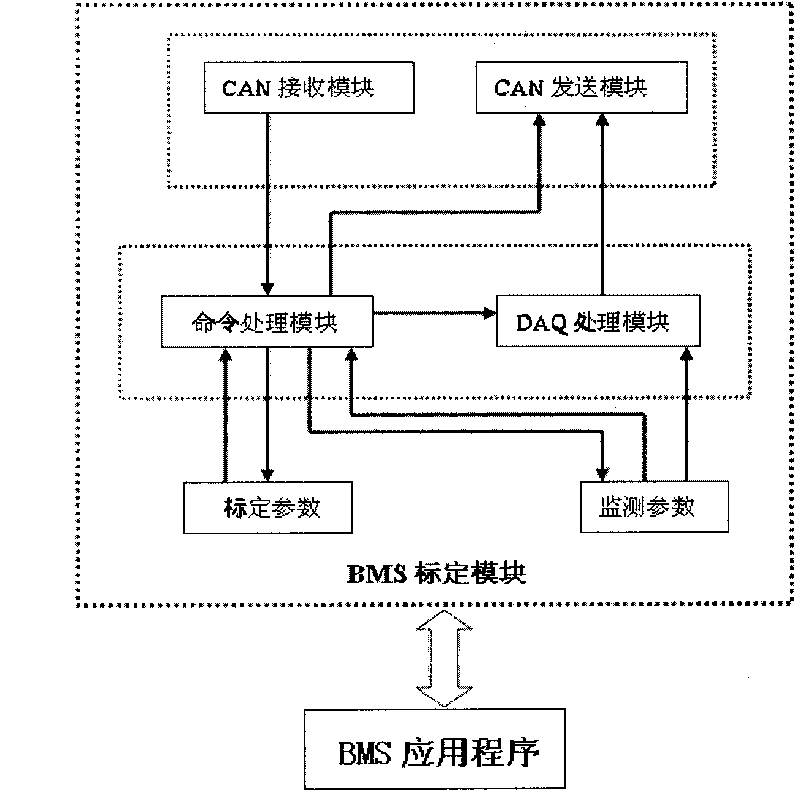

[0010] Such as figure 1 Shown is a schematic block diagram of the BMS calibration module of the present invention, and the BMS calibration module belongs to the lower computer, that is, the BMS side. The core controller of the calibration module, the digital signal processor DSP, is used as the upper controller. After the address / data bus is buffered by the buffer through the input / output I / O interface, it writes the control command and the status of the independent CAN bus controller. Data reading, at the same time, DSP controls the complex logic control device CPLD through the I / O interface output control word, so that it outputs chip selection and read and write control signals to the independent CAN bus controller, and the DSP controls the independent CAN bus controller to send and Receive the calibration information, and realize the calibration of the BMS through the CAN communication circuit. The CAN communication circuit can use a combination of an optocoupler isolation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com