Wind power generation system for direct-drive dual stator-winding induction generator

A technology of wind power generation system and stator double winding, applied in asynchronous generator control, control of generator through magnetic field changes, etc., can solve the problem that the switching harmonics of the converter are easy to inject into the load, increase the difficulty and cost of post-stage high-voltage direct current transmission, The problem of the large capacity of the converter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

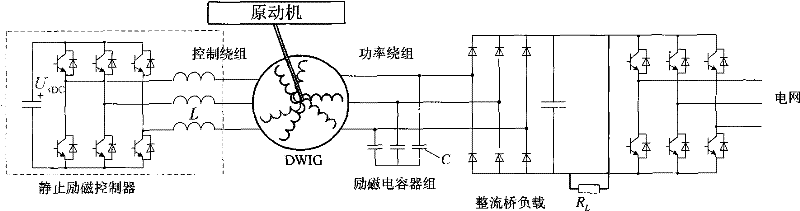

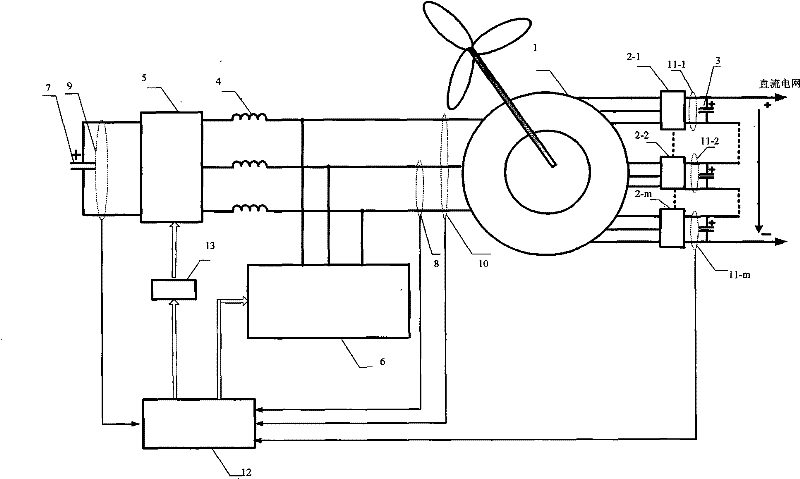

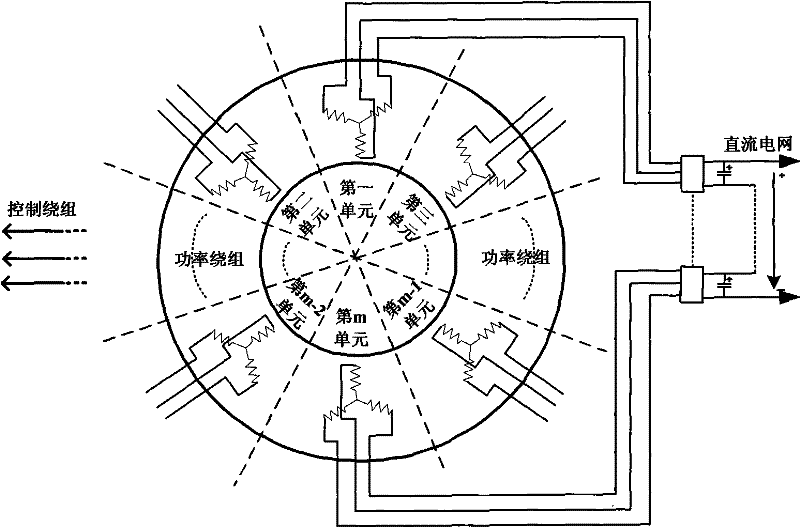

[0017] Depend on figure 2 It can be seen that the stator double-winding asynchronous motor power generation system of the present invention includes a direct-drive stator double-winding asynchronous generator 1, a rectifier bridge 2-1, 2-2 ... 2-m, a power winding side DC capacitor 3, a filter inductor 4, an excitation Transformation 5, excitation capacitor bank 6, main circuit composed of control side DC capacitor 7; detection circuit composed of current sensor 8, voltage sensor 9, 10, 11-1, 11-2, ... 11-m; digital signal A control loop composed of a processor 12 and a drive circuit 13 controlling the converter. The switching tube of the control converter can adopt IGBT or intelligent power module IPM. First, the capacitor bank on the control side is self-excited to build the voltage, and the voltage on the control side of the generator is rectified by the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com