Radiating device

A technology of heat dissipation device and radiator, applied in heat exchange equipment, indirect heat exchanger, lighting and heating equipment, etc., can solve the problems of low heat dissipation efficiency and uneven heat distribution of heat dissipation device, and achieve high heat dissipation efficiency and increase The effect of thermal contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

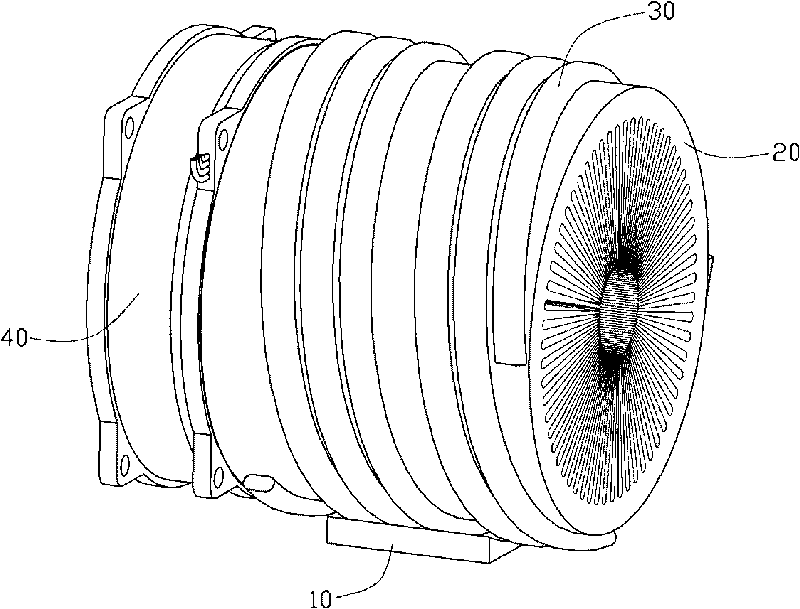

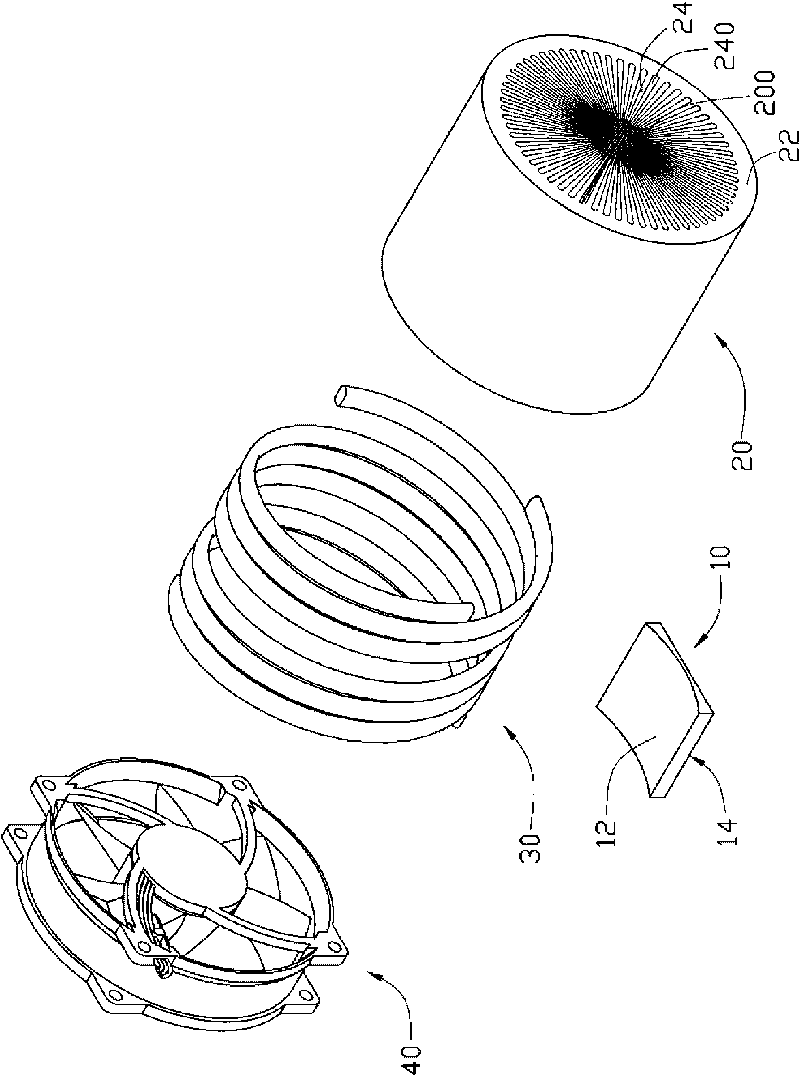

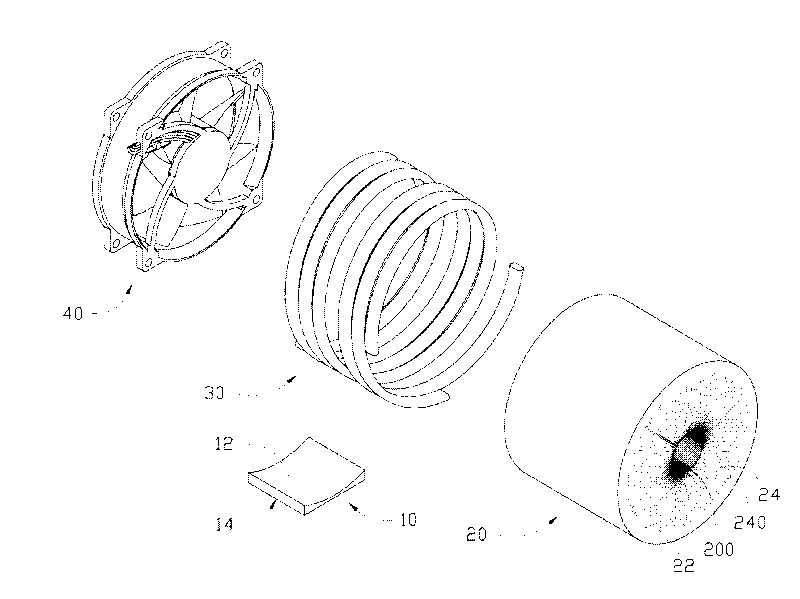

[0009] Such as figure 1 As shown, the heat dissipation device according to an embodiment of the present invention is used to dissipate the heat generated by the electronic components (not shown) combined with it. The heat dissipation device includes a hollow cylindrical radiator 20 , a plurality of heat pipes 30 spirally surrounding the outer surface of the radiator 20 , a base 10 combined with the heat pipes 30 and a fan 40 arranged at one end of the radiator 20 .

[0010] Please also refer to figure 2 , the base 10 is integrally formed by metal materials with good thermal conductivity such as copper and aluminum, and has a curved surface 12 at the top and a flat surface 14 at the bottom. The curved surface 12 is in direct contact with the heat pipe 30 and is in contact with the radiator 20 The curvature of the curved surface 12 is consistent with the curvature of the heat pipe 30 in contact with it and the curvature of the outer surface of the heat conducting cylinder 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com