Circular tea of Camellia chrysantha and processing method

A processing method, the technology of golden camellia, which is applied in the field of tea and processing, can solve the problems of maintaining pressed and formed tea, and achieve the effect of maintaining nutritional components and functional factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

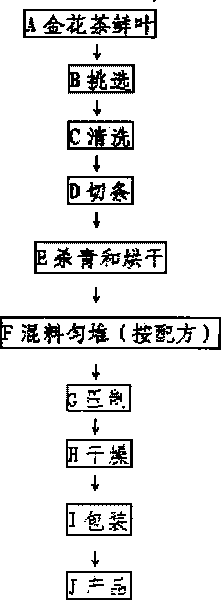

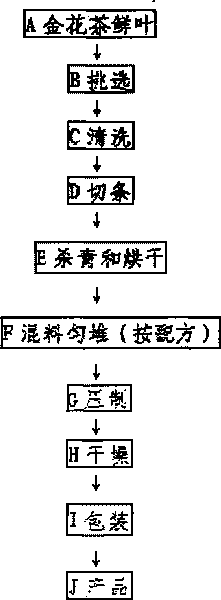

Method used

Image

Examples

Embodiment 1

[0038] Take 100 kg of freshly picked golden camellia leaves, manually select to remove impurities, rotten and diseased yellow leaves in the fresh leaves, clean the fresh golden camellia leaves with clean water, drain the water, and then put the fresh golden camellia leaves into the reciprocating straight line Cut into 1-2cm wide leaflets in a type herb cutting machine, and then put them into a microwave fixing and drying equipment with a power of 24KW and a wavelength of 12.26cm to fix and dry for 10 minutes until the moisture content of the tea leaves is less than 12%; then, put Mulberry leaves and golden flower tea leaves are mixed and evenly piled according to the ratio of 1:2.5; 150 grams of mixed and evenly piled tea leaves are weighed and put into a 50-ton automatic hydraulic tea machine for pressing and shaping for 3 minutes, and round tea pieces are obtained after removing the template Then put it on a stainless steel tray and put it in a hot air circulation oven to dry...

Embodiment 2

[0040]Take 50 kg of fresh golden camellia leaves, manually select to remove impurities, rotten and diseased yellow leaves in the fresh leaves, clean the fresh golden camellia leaves with clean water, drain the water, and then put the fresh golden camellia leaves into the reciprocating straight line Cut into leaflets with a width of about 2cm in a type herb cutting machine, and then put them into a microwave fixing and drying equipment with a power of 24KW and a wavelength of 12.26cm, and finish and dry them for 11 minutes until the moisture content of the tea leaves is less than 11%; then, the mulberry Leaves and golden camellia tea leaves are mixed and evenly piled according to the ratio of 1:2; 150 grams of mixed and evenly piled tea leaves are weighed and put into a 50-ton automatic hydraulic tea machine for pressing and shaping for 3.5 minutes. After removing the template, round tea pieces are obtained Put it on a stainless steel tray and put it in a hot air circulation ove...

Embodiment 3

[0042] Take 85 kg of fresh golden camellia leaves, manually select them to remove impurities, rotten and diseased yellow leaves, clean the fresh golden camellia leaves with clean water, drain the water, and then put the fresh golden camellia leaves into the reciprocating straight line Cut into leaflets with a width of about 1.5cm in a type medicine cutting machine, and then put them into a microwave fixing and drying equipment with a power of 24KW and a wavelength of 12.26cm, and finish and dry for 8 minutes until the moisture content of the tea leaves is less than 14%; then, weigh Take 150 grams of evenly piled Jinhua tea leaves and put them into a 50-ton automatic hydraulic tea machine for pressing and setting for 2.5 minutes. After removing the template, you can get round tea pieces, put them on stainless steel trays, put them in a hot air circulation oven to dry, and heat them at 60°C. , dry at a constant temperature for 50 minutes to make the moisture content ≤ 12%, and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com