Hydrocracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of low performance of hydrodesulfurization and hydrodecarbonization and other problems to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

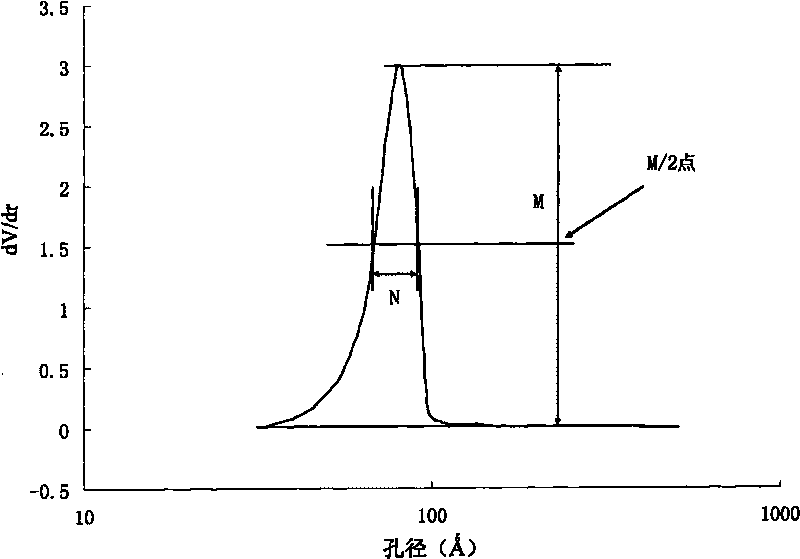

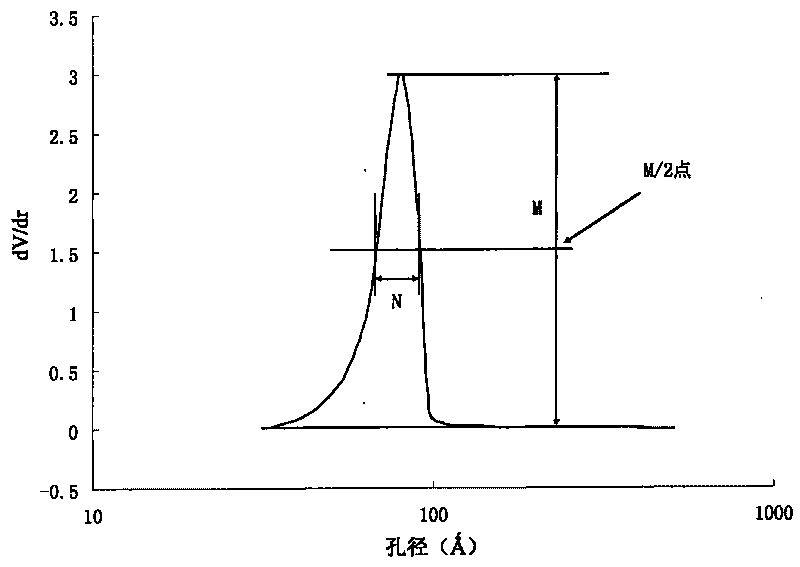

[0023] The preparation method of the hydrocracking catalyst provided by the present invention includes loading the hydrogenation active component and the IVB group metal component in the periodic table on the carrier respectively, wherein the carrier has a pore structure, and the pore structure The most probable pore diameter is 6-14 nanometers, and the pore concentration is more than 7. The pore concentration refers to the ratio of the peak height to the half maximum width in the distribution curve of the differential of the specific pore volume to the pore diameter versus the pore diameter.

[0024] The steps of drying and calcining can be performed after each contact, or after all contacts.

[0025] Wherein, the pore distribution and types of the carrier have been described in detail above, and will not be repeated here.

[0026] In the process of preparing the hydrocracking catalyst, the amount of each substance is based on the total amount of the catalyst, and the content...

Embodiment 1

[0046] This example illustrates the preparation of the hydrocracking catalyst provided by the present invention.

[0047] Take by weighing 150 grams of SD-2 powder (purchased from Changling Catalyst Factory, produced in 2004, alumina content 64.4%, specific surface area 268m 2 / g, the diameter of several pores is 9.7nm, and the concentration of pores is 4.1), extruded into a butterfly bar with a circumcircle diameter of 1.4 mm with an extruder, and dried at 120°C for 6 hours. Then, the carrier was calcined for 3 hours at 600° C. under the condition of flowing air, and the air flow rate was 1.6 cubic meters / kg·hour. The pore structure of the carrier is measured by the BET method, and the distribution curve of the differential (dV / dr) of the specific pore volume to the pore diameter (dV / dr) with the pore diameter is obtained, such as figure 1 shown.

[0048] Weigh ammonium fluotitanate according to the loading capacity of titanium oxide at 12% by weight, add 65ml of water, dis...

Embodiment 2

[0051] This example illustrates the preparation of the hydrocracking catalyst provided by the present invention.

[0052] Take by weighing 150 grams of CL powder (purchased from Changling Catalyst Factory, the 147th batch produced in 2007, alumina content 72.8%, specific surface area 299m 2 / g, several pore diameters 14.5nm, pore concentration 3.6), extruded into a cylindrical strip with a circumscribed circle diameter of 1.1 mm with an extruder, and dried at 150°C for 4 hours. Then, the carrier was calcined for 4 hours under the condition of 580° C. under the condition of flowing air, and the air flow rate was 1.1 cubic meters / kg·hour. The BET method was used to measure the most probable pore size and pore size concentration of the carrier, and the results are shown in Table 1.

[0053] Weigh ammonium fluozirconate according to the loading capacity of zirconia at 8% by weight, add 85ml of water, dissolve under stirring, mix this solution with 100 grams of carrier, keep it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com