Spiral grading sieve

A technology of spiral grading and screw, which is applied in the field of grading sieves, can solve the problems of small sieve wear, high screening efficiency, blockage, etc., and achieve the effect of small wear and high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

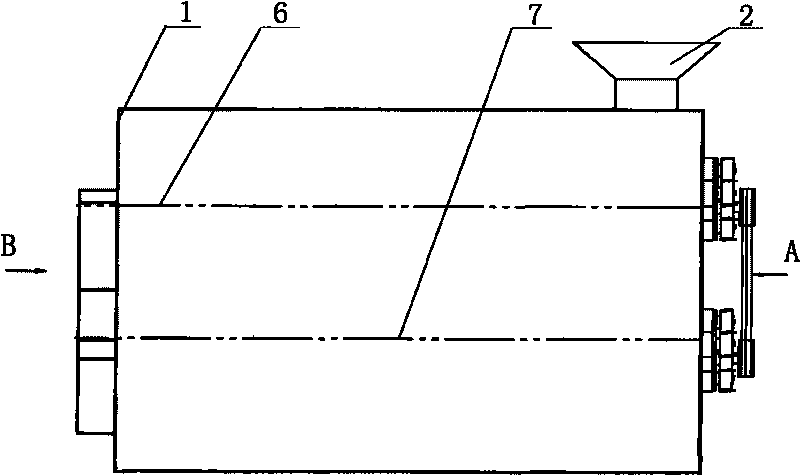

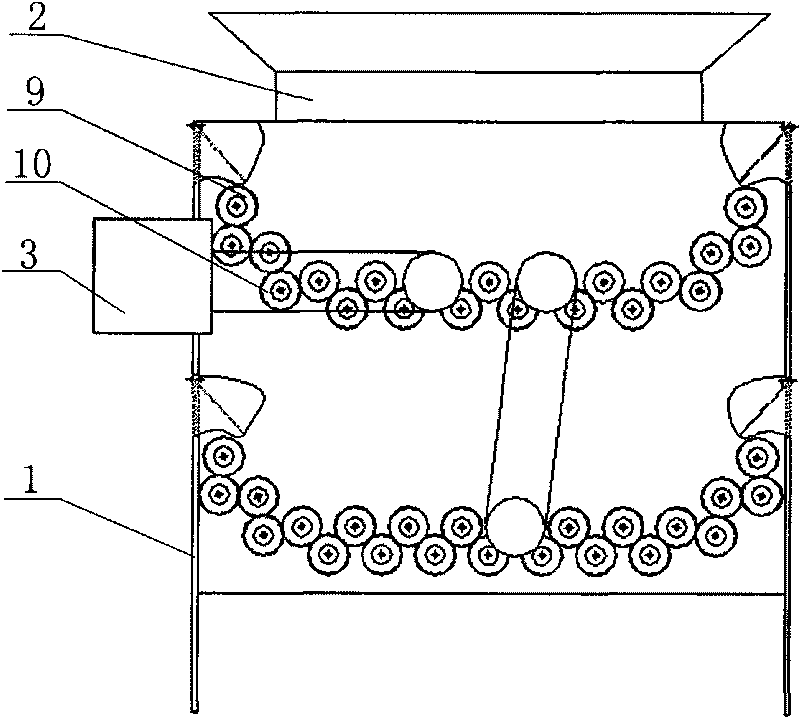

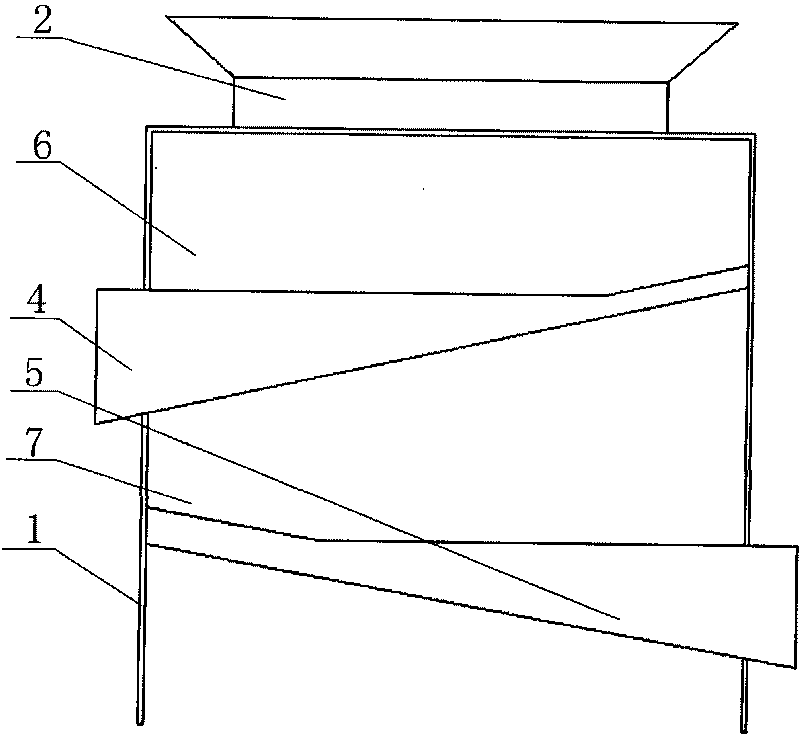

[0007] see figure 1 combine figure 2 , image 3 , Figure 4 As shown, this specific embodiment comprises frame 1, is fixed with feed port 2, diesel engine 3, one-layer discharge port 4 and two-layer discharge port 5 on frame 1, feed port 2 and one-layer discharge port A layer of screen surface 6 is installed between 4, and a second layer of screen surface 7 is installed between the first layer of discharge port 4 and the second layer of discharge port 5. 8 form a "concave" type, and the thread ribs and grooves on the adjacent screw 8 form a screen hole. The end of the screw 8 is fixed with a gear 9, and the gear 9 on the adjacent screw 8 meshes with the idler gear 10 below it. A screw rod 8 in the screen surface 6 and the diesel engine 3 are driven by a belt, and another screw rod 8 in the first layer of screen surface 6 and a screw rod 8 in the second layer of screen surface 7 are also driven by a belt. The pitch of the screw rod 8 in the second layer of screen surface 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com