Preparation method of special iron powder for metal object surface spraying and embedding technology

A metal object and technology technology, applied in the field of preparation of metal nano-powder, can solve the problems of unsatisfactory shape of iron powder particles, and achieve the effect of low cost and less use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

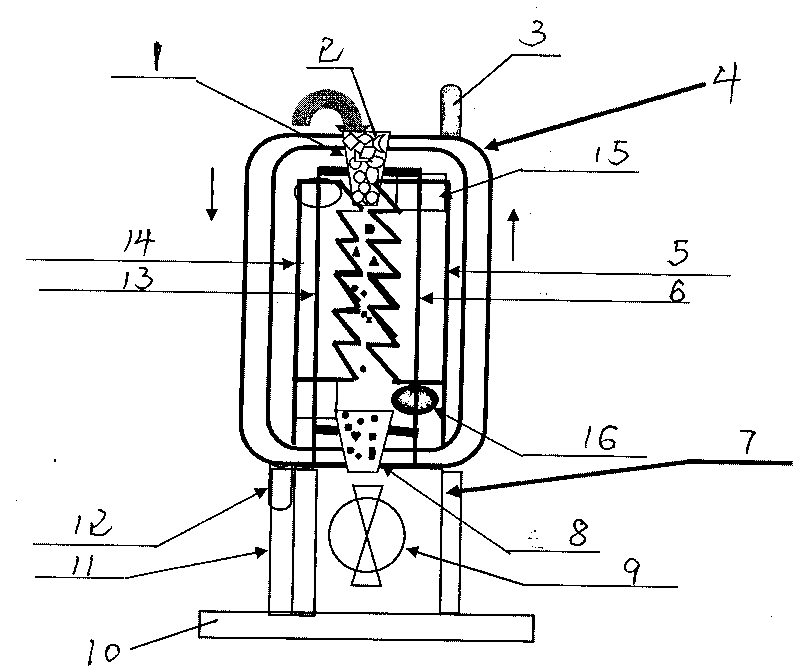

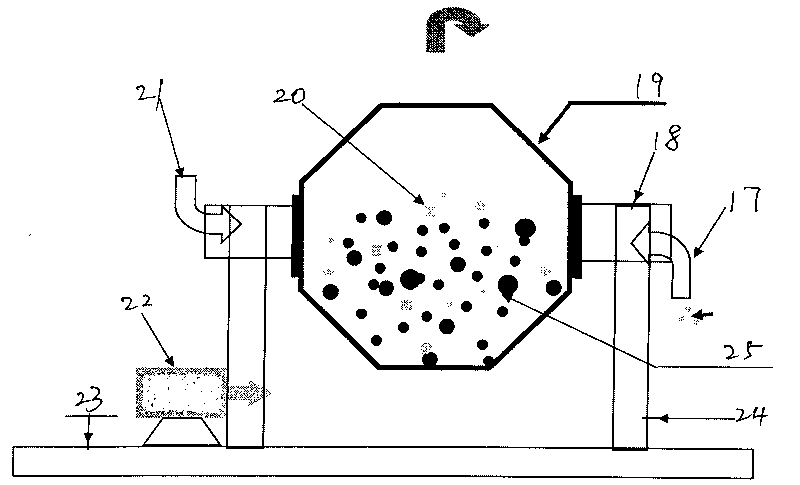

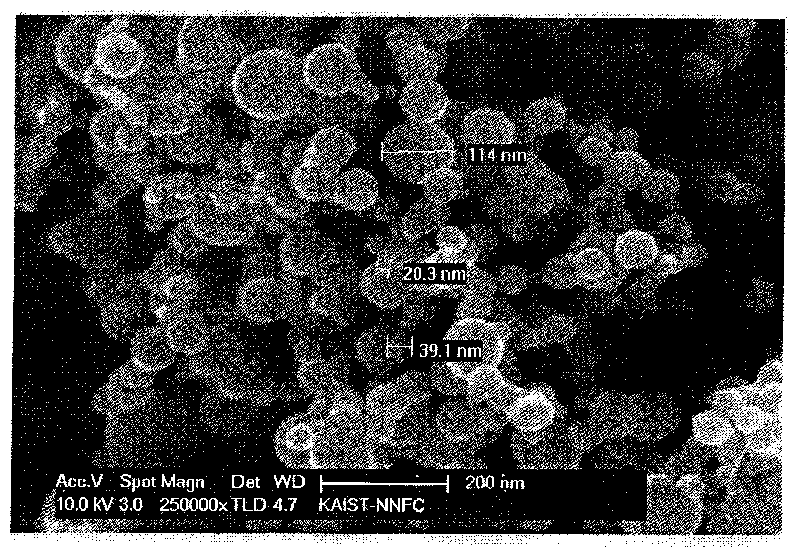

[0019] Embodiment 1: a kind of preparation method of special iron powder of metal object surface spray embedding technology, comprises the following steps: (the specific processing method refers to the metal nano-powder zero-boundary particle cutting production process that the patent application number is 2006100481685 record,) at -5 Under the condition of ℃, the number of times of high-frequency cutting is set at 6500 times per minute to produce and process the nano-iron powder of the special spraying and embedding technology with the powder particle shape as a sphere, and then sort out (50nm as an example) D3= 21nm D25=32.5nm D50=50nm D75=63.2nm D97=77.3nm particle distribution powder material, and then use the "DQ coating method" to continue the anti-oxidation coating of iron powder particles with a thickness of 2nm-3nm, The anti-oxidation time is more than 90 hours, and the coated powder material is input into a high-speed grinder for surface grinding of powder particles, ...

Embodiment 2

[0024] Embodiment 2: A preparation method of iron powder specially used for spraying and embedding technology on the surface of metal objects, comprising the following steps: producing and processing powder particles under the condition of 5°C and setting the frequency of high-frequency cutting at 6000 times per minute The shape is the nano-iron powder of the special spray embedding technology of the sphere, and then sort the powder material with the particle distribution of D3=21nm D25=32.5nm D50=50nm D75=63.2nm D97=77.3nm respectively (50nm as an example), and then , and then use the "DQ coating method" to continue the anti-oxidation coating of iron powder particles with a thickness of 2nm-3nm, so that the anti-oxidation time can reach more than 90 hours, and the coated powder material is input into a high-speed grinder for grinding. Surface grinding treatment of powder particles.

Embodiment 3

[0025] Embodiment 3: A method for preparing iron powder for spraying and embedding technology on the surface of metal objects, comprising the following steps: producing and processing powder particles under the condition of 0°C and setting the frequency of high-frequency cutting at 6250 times per minute The shape is the nano-iron powder of the special spray embedding technology of the sphere, and then sort the powder material with the particle distribution of D3=21nm D25=32.5nm D50=50nm D75=63.2nm D97=77.3nm respectively (50nm as an example), and then , and then use the "DQ coating method" to continue the anti-oxidation coating of iron powder particles with a thickness of 2nm-3nm, so that the anti-oxidation time can reach more than 90 hours, and the coated powder material is input into a high-speed grinder for grinding. Surface grinding treatment of powder particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com