Integrated device for dust adsorption and air-entrapping

A gas filling device and gas blowing device technology, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of human injury, dust suction, gas filling port and workpiece cannot meet the needs, laser processing quality decline, etc. problems, to achieve the effect of easy maintenance, good dust collection effect, safe and reliable maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

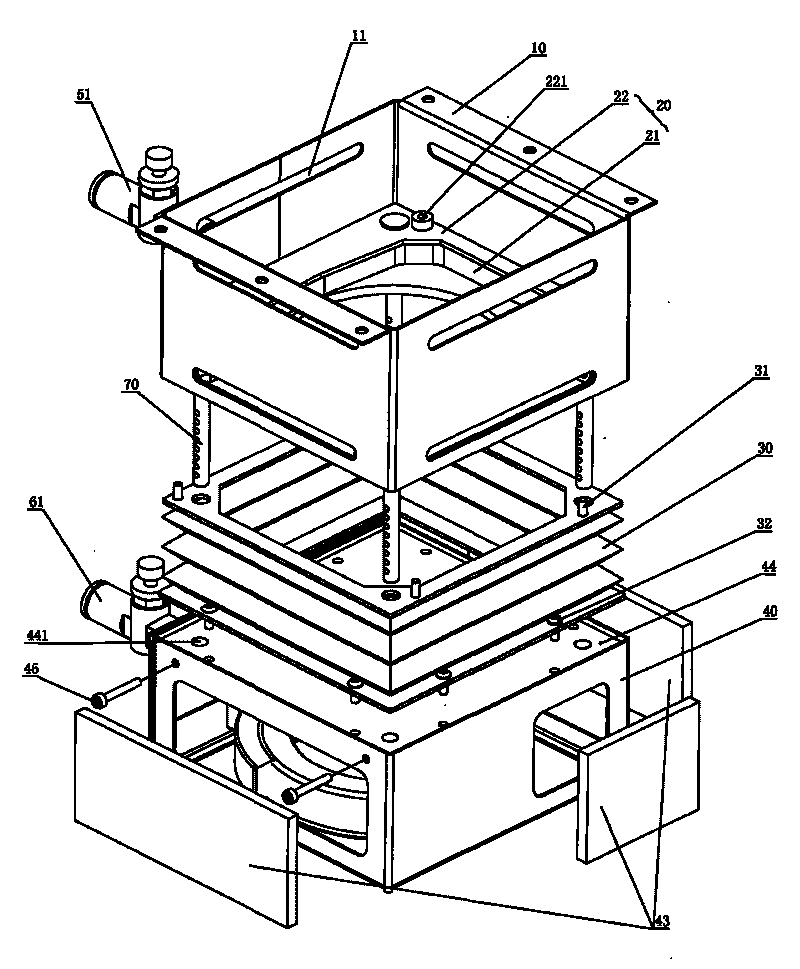

[0024] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0025] The invention relates to the field of laser processing, in particular to a height-adjustable integrated device for dust collection and air filling that uses the scanning function of a vibrating mirror and a vacuum adsorption workbench for absorbing workpieces in laser processing.

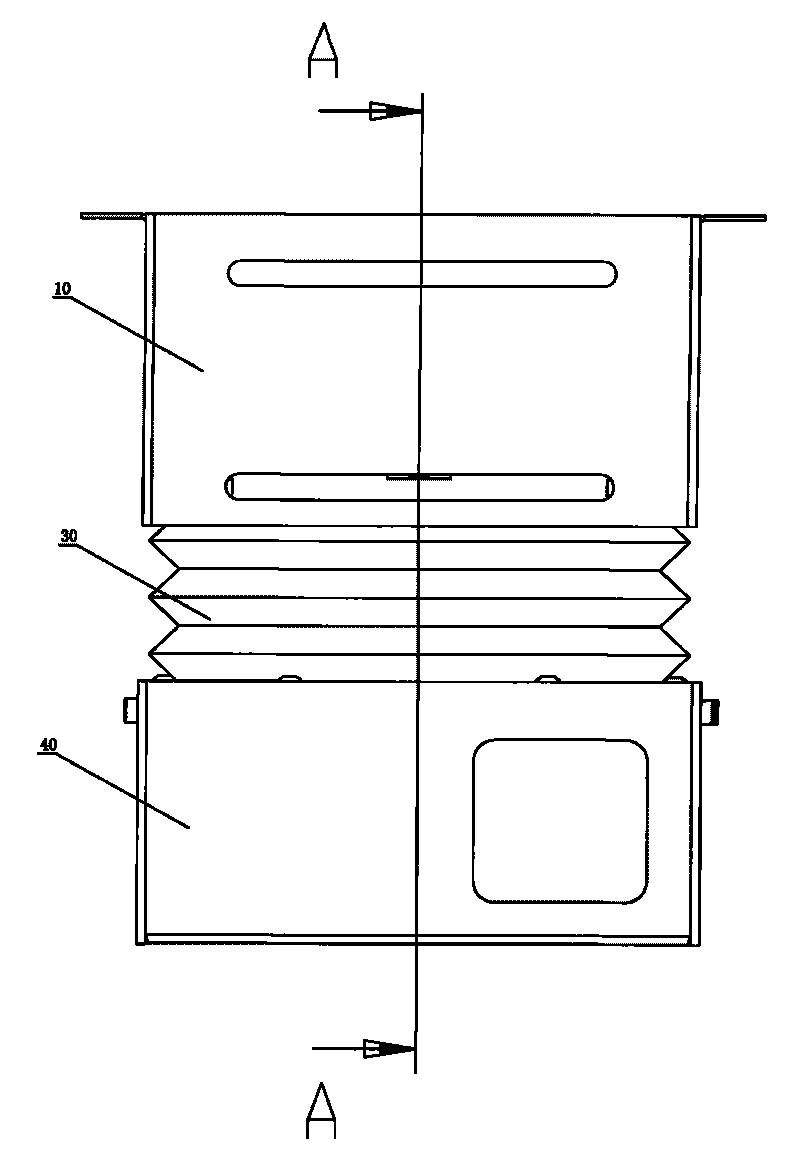

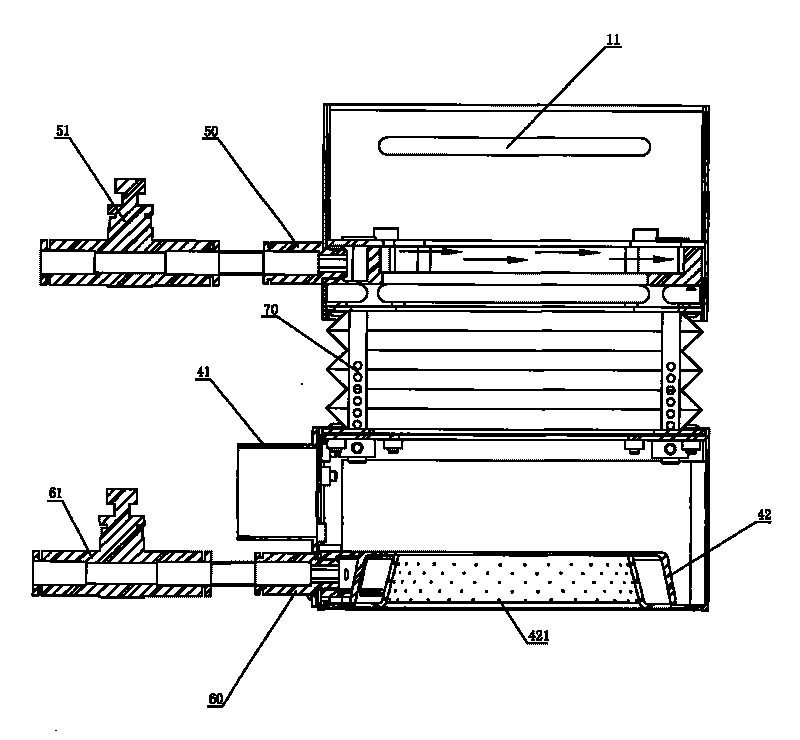

[0026] Figure 1 to Figure 3 Shown is a schematic structural diagram of the dust collection and air filling integrated device of the present invention. The dust suction and air filling integrated device is composed of four parts, the first part is the upper part, which is a shell-shaped lens cleaning protective cover 10; the second part is the lens blowing device 20 arranged inside the first part, and the lens blowing device 20 includes a lens blowing cavity 21 located inside the lens cleaning protective cover 10 and a flange located on the lens cleaning protective cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com