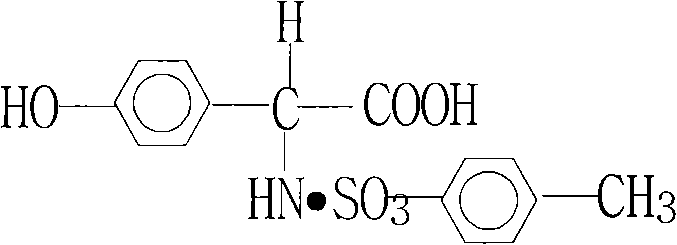

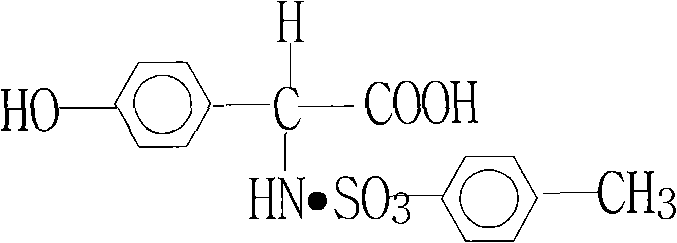

Technology for hydrolyzing D-(-)-p-hydroxyphenylglycine-p-toluenesulfonate

A technology of p-hydroxyphenylglycine and toluene sulfonate is applied in the production field of pharmaceutical chemical intermediates and can solve the problems of low yield, poor quality and high cost of L-p-hydroxyphenylglycine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. First add 2500 kg of pure water into the 5000L reactor, start stirring and put in 1000 kg of purified D salt, and open the steam valve to raise the temperature.

[0016] 2. After heating up and dissolving, add 10 kg of activated carbon for decolorization, keep warm at 85-90°C for 30 minutes, and then filter while it is hot.

[0017] 3. Add 5 kg of EDTA catalyst to the filtered mother liquor, neutralize it with ammonia water, and adjust the pH between 4.2-4.4.

[0018] 4. Cool down to 30°C and keep warm for 2 hours, then centrifuge.

[0019] 450-460 kg of pure L-p-hydroxyphenylglycine can be obtained, and the quality is as follows:

[0020] Content≥99.5%

[0021] Absorption≤0.050

[0022] Optical rotation: -156°~-161°

[0023] Single impurity≤1ppm

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com