Energy-saving agent special for roller and leather roller of textile machine and preparation method thereof

An energy-saving agent and roller technology, which is applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of insignificant energy-saving effect of rollers and top rollers, and achieve the effect of prolonging the life of the spinning machine, stable performance, and favorable for popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

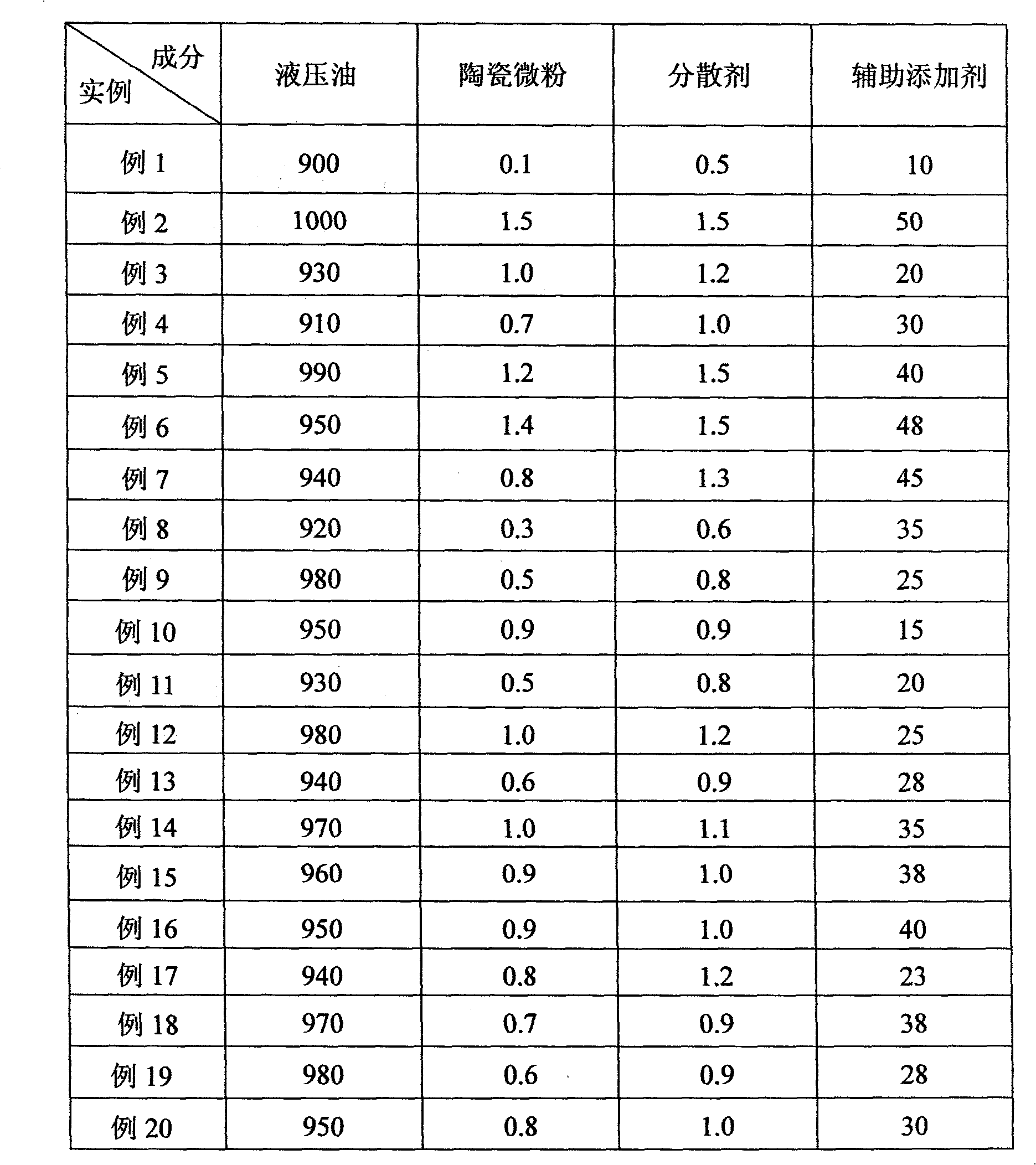

[0034] Embodiment 1: A special energy-saving agent for textile machine rollers and top rollers, expressed in percent by weight. The raw material components are shown in Table 1. The raw materials are 900-1000 parts of hydraulic oil, 0.1-1.5 parts of ceramic micropowder, and 0.5-1.5 parts of dispersant parts, 10-50 parts of auxiliary additives.

[0035] Among them, the hydraulic oil is HL100 hydraulic oil, which is commercially available, and the manufacturers include Great Wall, Kunlun, Zhongshi, etc.; the ceramic micropowder is nanoscale ceramic micropowder, with a particle size of 10-80nm; SD series ceramic powder dispersant, such as SD-00 or SD-03, the particle size is 50-100nm; the auxiliary additive is tetrapolyoxypropylene derivative of amine.

[0036]Among them, SD series ceramic powder dispersant is an electrolyte type anti-flocculation agent. The activated group can effectively adsorb on the surface of the particle. The electrostatic repulsion and space barrier effect...

Embodiment 2

[0039] Embodiment 2: A special energy-saving agent for textile machine rollers and top rollers, expressed in percent by weight. The raw material components are shown in Table 1, wherein the hydraulic oil is HL100 hydraulic oil, and the ceramic micropowder is nano-scale ceramic micropowder, with a particle size of 10-80nm ; The dispersant is a nano-scale ceramic powder dispersant, adopting SD-00 ceramic powder dispersant, the particle size is 50-100nm; the auxiliary additive is tetrapolyoxypropylene derivative T1001 of amine.

[0040] Preparation method: Add ceramic micropowder and dispersant to a ball mill, grind for 1-2 hours at room temperature, then add HL100 hydraulic oil to the ground material and mix, then put the mixture into a mixing tank, add auxiliary additives, and stir for 1-2 hours Just 2 hours, the stirring speed is 1200~2000 rev / min.

Embodiment 3

[0041] Embodiment 3: A special energy-saving agent for textile machine rollers and top rollers, expressed in percent by weight, the raw material components are shown in Table 1, wherein the hydraulic oil is HL100 hydraulic oil, the ceramic powder is nano-scale ceramic powder, and the particle size is 30-60nm ; The dispersant is a nano-scale ceramic powder dispersant, using SD-03 ceramic powder dispersant, the particle size is 60-90nm; the auxiliary additive is tetrapolyoxypropylene derivative T1001 of amine.

[0042] Preparation method: Add ceramic micropowder and dispersant to a ball mill, grind for 1.5-2 hours at room temperature, then add HL100 hydraulic oil to the ground material and mix, then put the mixture into a mixing tank, add auxiliary additives, and stir for 1.5- 2 hours is enough. The stirring speed is 1200~1800 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com