Energy-saving heat conducting oil drying cylinder for sizing machines and sizing-dyeing machines

A technology of sizing and dyeing combined machine and heat transfer oil, which is applied in drying, drying machines, heating devices, etc., can solve the problems of large heat loss, affecting weaving efficiency, unstable steam pressure, etc., and achieves small heat loss and energy saving Effects of consumption and reduction of gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

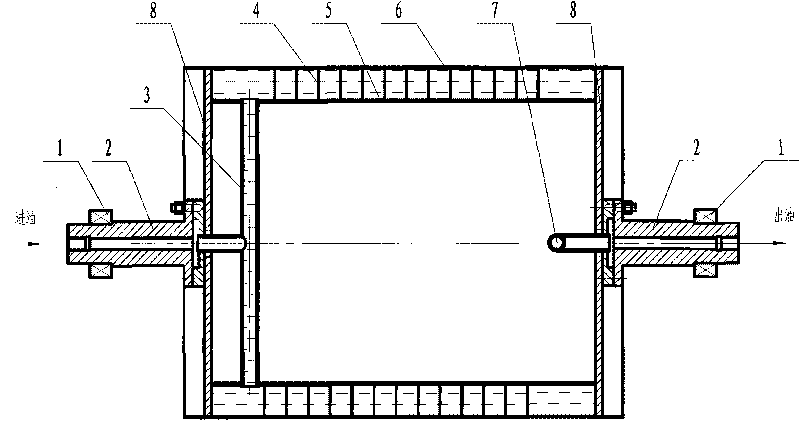

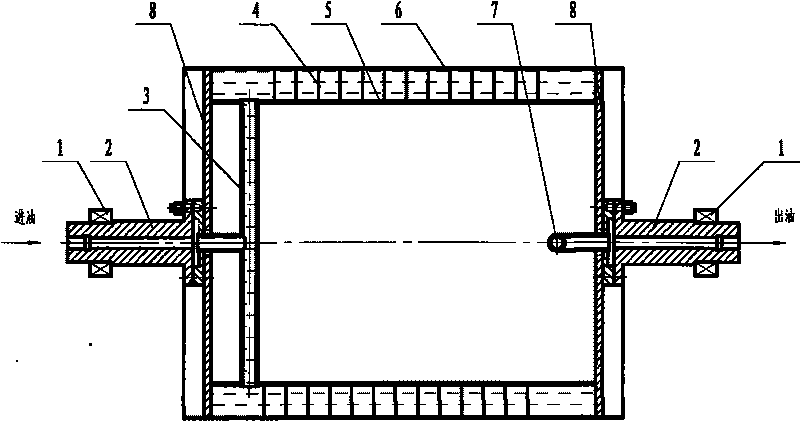

[0016] Describe the present invention in detail below in conjunction with accompanying drawing:

[0017] Such as figure 1 As shown, the present invention comprises cylinder body 6, sealing head 8, axle head 2, bearing 1 and driving device and control system, and the driving device and control system of this machine described here, is the driving device and control system commonly used at present, Not described in detail here. A liner 5 is provided in the cavity of the cylinder 6, and the two ends of the cylinder 6 and the liner 5 are respectively fixed on the inner surfaces of the two heads 8, so that the interlayer between the inner surface of the cylinder 6 and the outer periphery of the liner 5 Constitutes a closed heat transfer oil chamber. A multi-head spiral oil guide groove 4 is fixed in the heat conduction oil cavity, so that the heat conduction oil enters and exits in the heat conduction oil cavity according to the track of the set spiral oil guide groove 4, which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com