Countercurrent tube bundle type wall-type heat exchanger

A technology of countercurrent tubes and heat exchangers, which is applied in the field of countercurrent tube row partition wall heat exchangers, which can solve the restrictions on the application and development of plate heat exchangers, and cannot be used in high-pressure or medium-pressure occasions, plate heat exchangers Low structural strength and other issues, to achieve significant energy-saving potential, easy disassembly, cleaning and maintenance, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

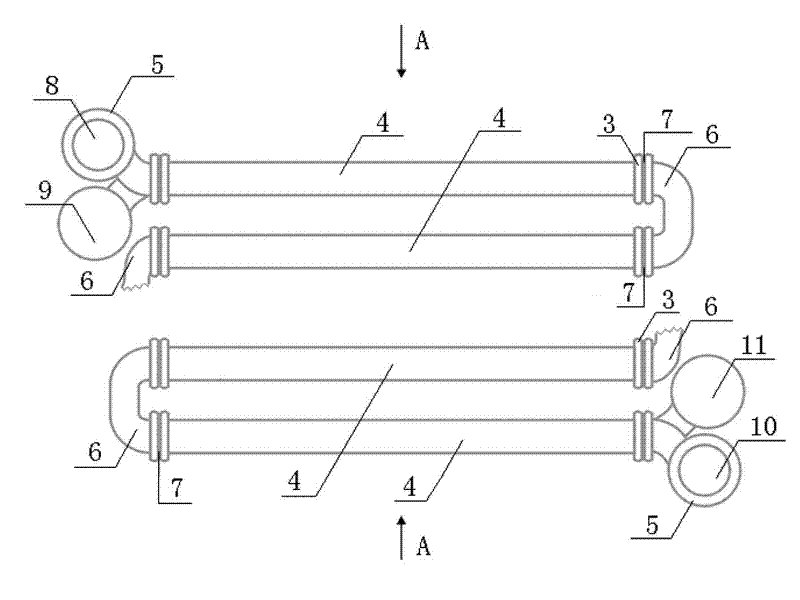

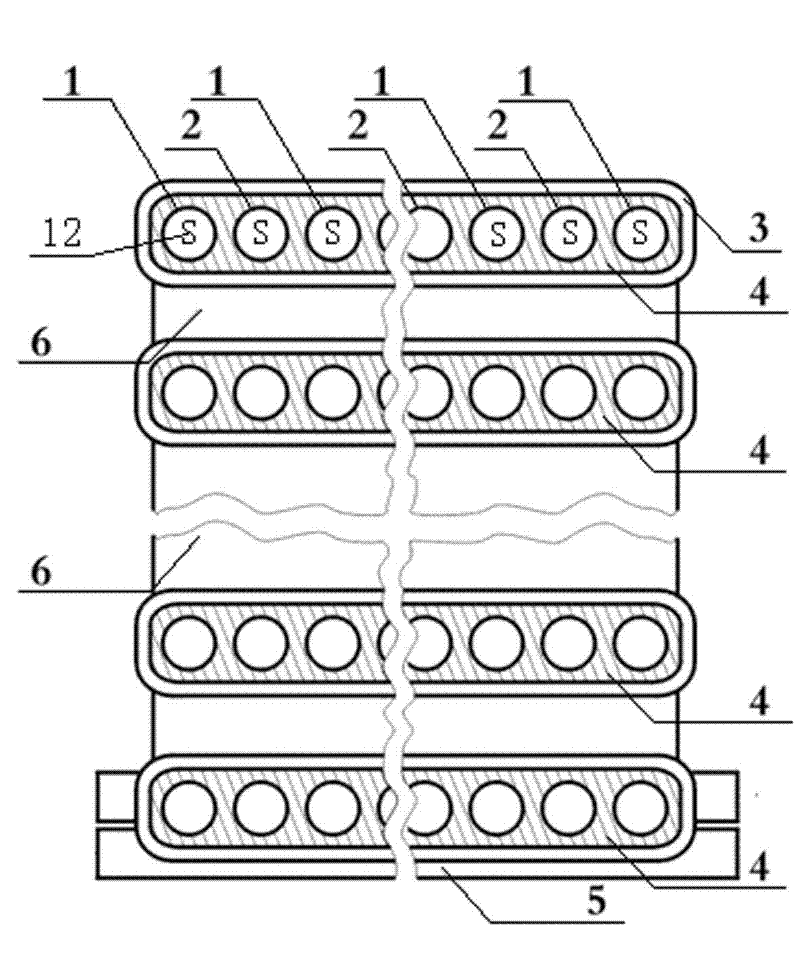

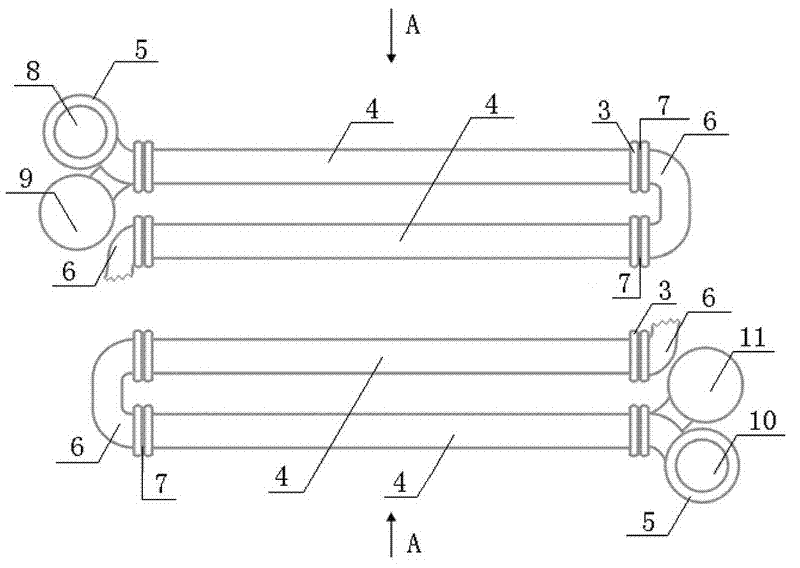

Embodiment 1

[0013] Referring to the accompanying drawings: The partitioned wall heat exchanger in this embodiment is composed of 1-50 heat exchange units connected in series, and each heat exchange unit is provided with 1-65 rows, a total of 2-200 rows with opposite flow directions and alternately arranged in parallel. The hot fluid pipe 1 and the cold fluid pipe 2, the heat exchange unit of this embodiment is a parallel straight pipe row, and the end of each heat exchange unit is connected with the connecting elbow row 6 through the end cover 3, and at one end of the heat exchanger The hot fluid inlet 8 and the cold fluid outlet 9 are connected through the hot end cold and hot fluid divider 5; the hot fluid outlet 10 and the cold fluid inlet 11 at the other end of the heat exchanger are connected through the cold end cold and hot fluid divider 5 . Heat insulation gaskets 7 are added at the joints of the parallel straight pipe rows and the connecting elbow rows to block the longitudinal t...

Embodiment 2

[0015] The difference from Embodiment 1 is that the heat exchange unit is a serpentine tube row, and the nozzles at both ends of the tube are directly connected to the hot and cold fluid divider 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com