Molding structure and method for laser-assisting base plate line

A laser-assisted, substrate-based technology, applied in the direction of improving the metal adhesion of insulating substrates, secondary processing of circuits and printed circuits, etc., can solve problems such as circuit short circuit, circuit stripping, open circuit, etc., to increase bonding force, reduce process cost, The effect of simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

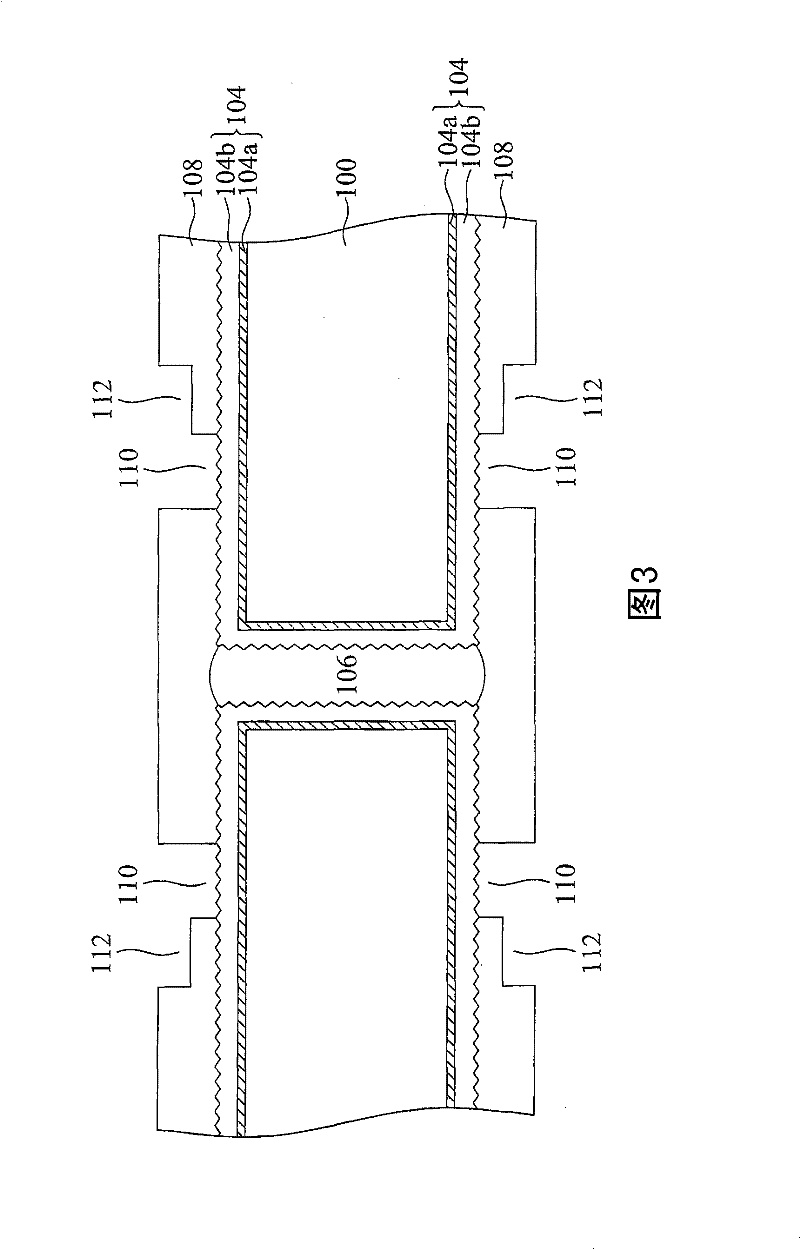

[0026] Hereinafter, the method of laser-assisted substrate circuit forming according to the embodiment of the present invention will be described in detail with the accompanying drawings. It should be noted that the multiple drawings are simplified schematic diagrams to emphasize the characteristics of the present invention, and therefore, the dimensions of the elements in the drawings are not drawn completely according to actual scale. Moreover, the embodiments of the present invention may also include elements not shown in the figure.

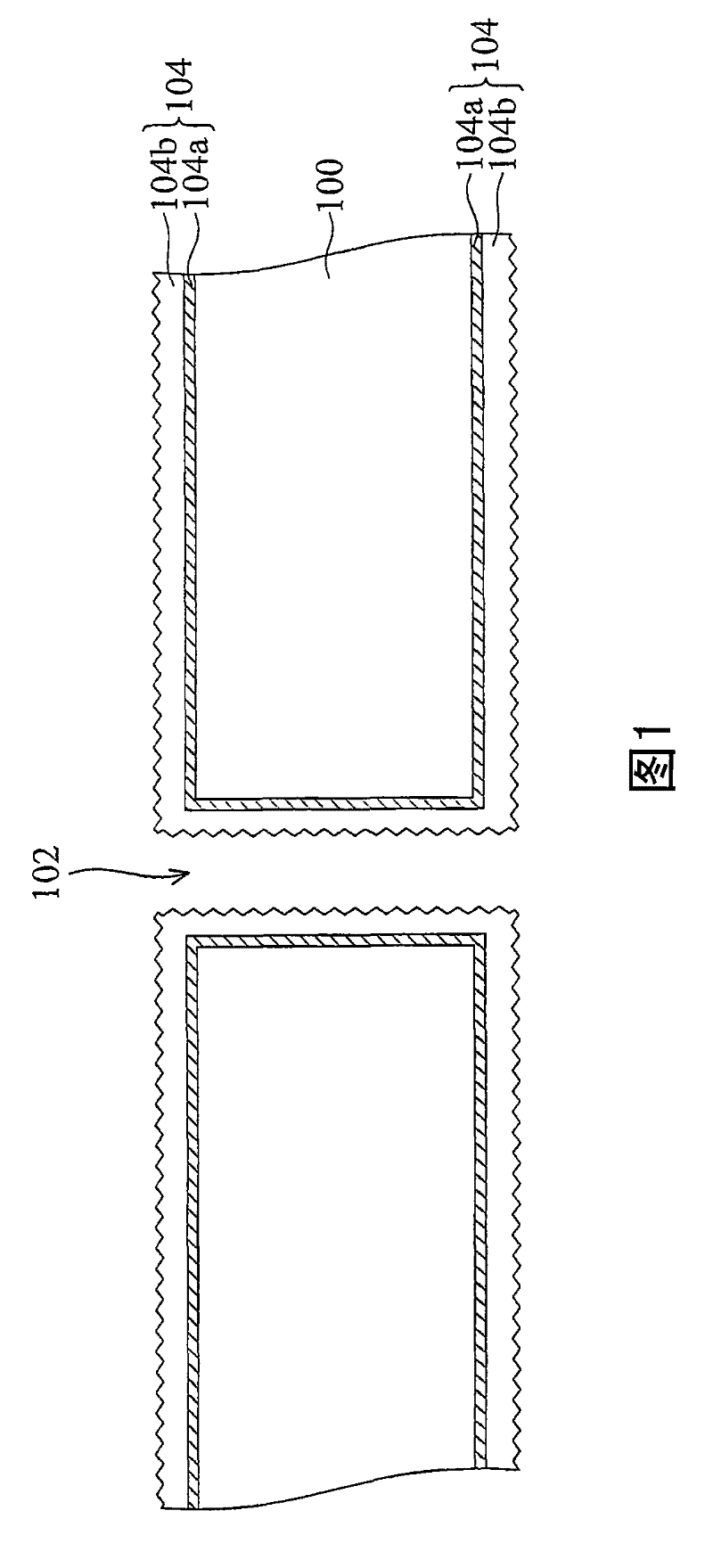

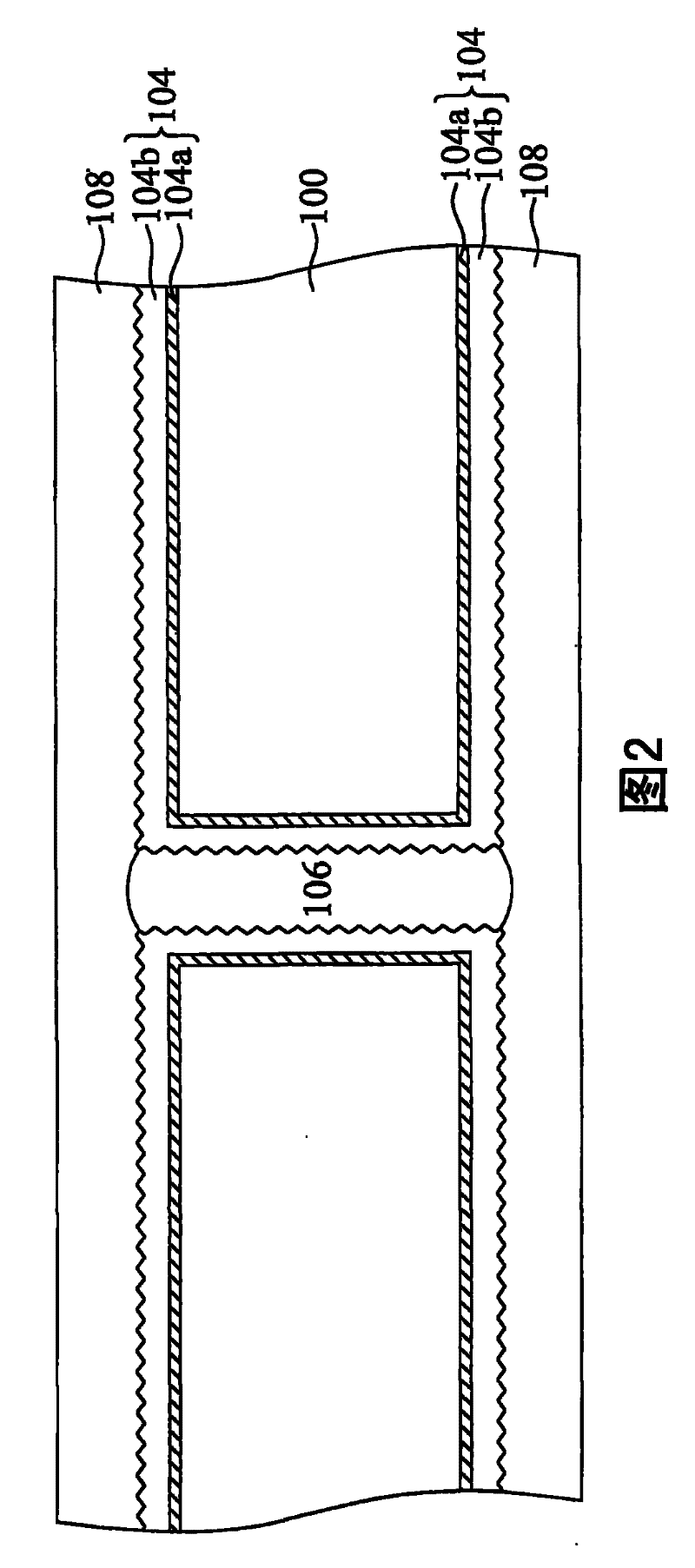

[0027] See Figure 1 to Figure 5 , The embodiment of the method for providing laser-assisted substrate circuit forming in the present invention will be described in detail. See figure 1 First, a circuit substrate 100 containing a plurality of through holes 102 is provided. The circuit substrate 100 includes paper phenolic resin, composite epoxy, and polyimide resin. resin) or glass fiber. The purpose of forming the via 102 is to establish a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com