Method for manufacturing table tennis bat

A table tennis racket and the technology of its manufacturing method are applied in the direction of rackets, sports accessories, etc., which can solve the problems of easy deterioration, mildew, and poor strength, and achieve the effects of light weight, easy and precise control, and high strength of the racket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

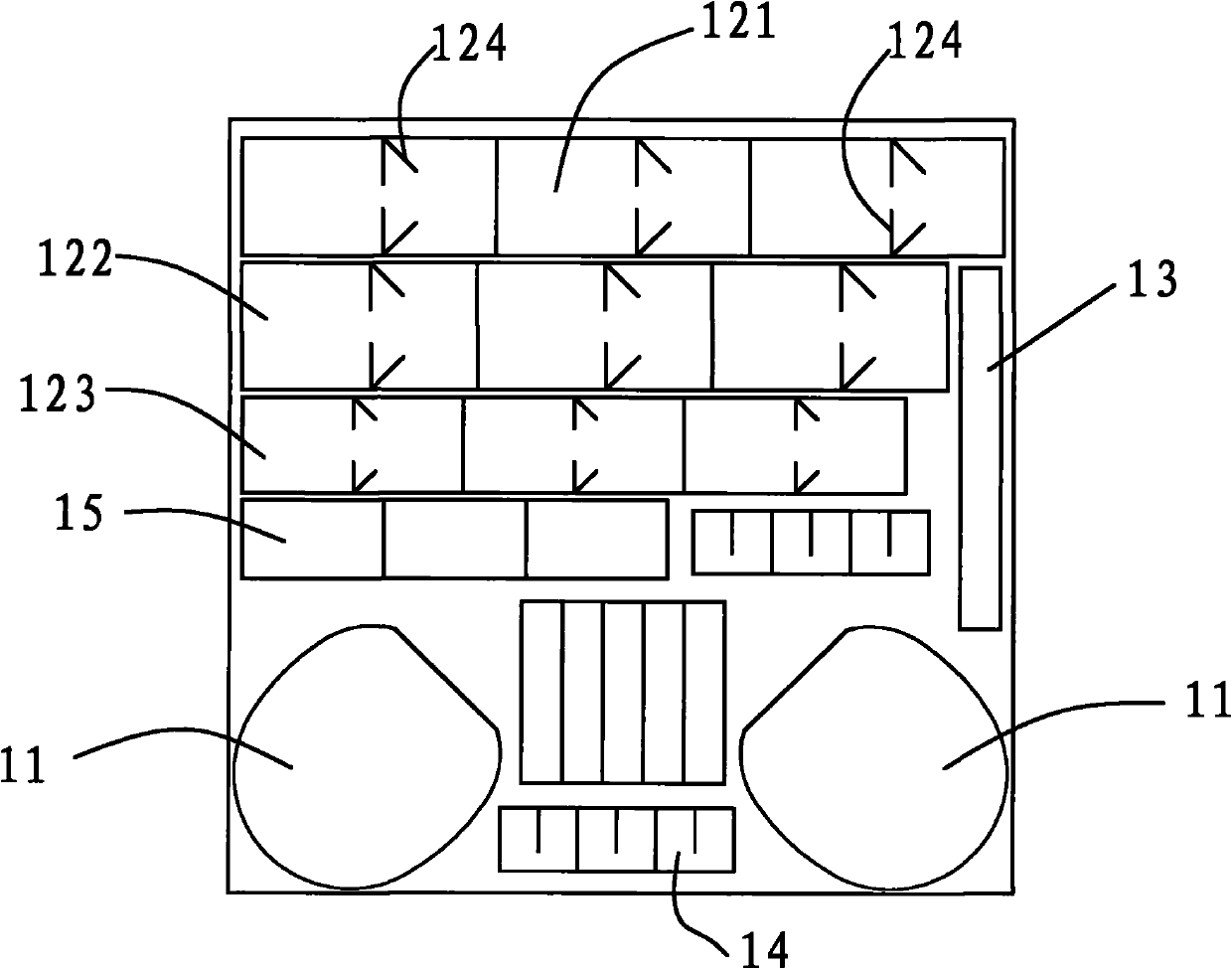

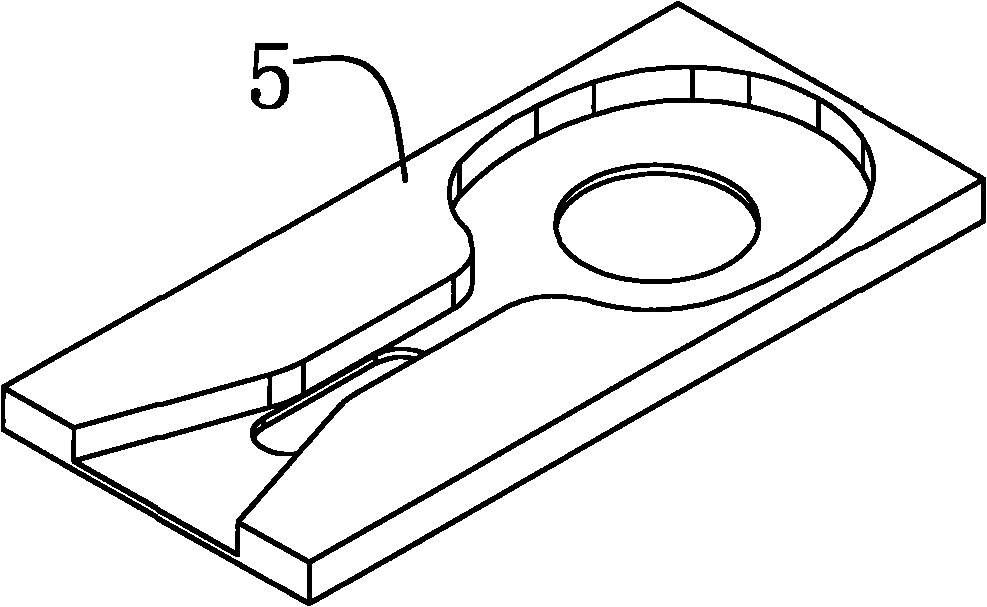

[0025] Please refer to each accompanying drawing together, the raw material that the table tennis racket manufacturing method of the present invention selects is mainly carbon fiber material or glass fiber material, also can both mix and use, because the two kinds of materials used are different in the craft of making table tennis racket. It is not large, and the specific ratio can be freely selected according to the needs. Due to the high cost of carbon fiber materials, the quality and performance of the obtained rackets are also good. Therefore, in practice, the content of carbon fiber materials can be generally controlled within the range of 20-100% based on the content of carbon fiber materials. Can meet the requirements.

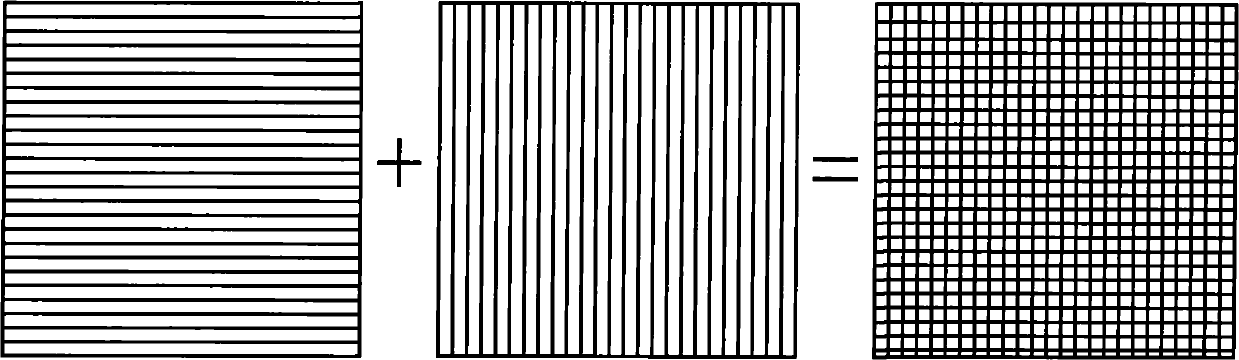

[0026] First, two uncut single-layer fiber materials, such as carbon fiber material cloth or glass fiber material cloth, are superimposed and pasted into a double-layer according to the fiber direction formed in them in a criss-cross manner, that is, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com