Powder distribution device, powder distribution method of powder distribution device and manufacturing method of NdFeB thin-sheet magnet

A technology of cloth powder and sheet, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of inconsistent powder distribution, uneven size of blanks and green bodies, unstable performance, etc., to reduce powder agglomeration , the effect of filling the same amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

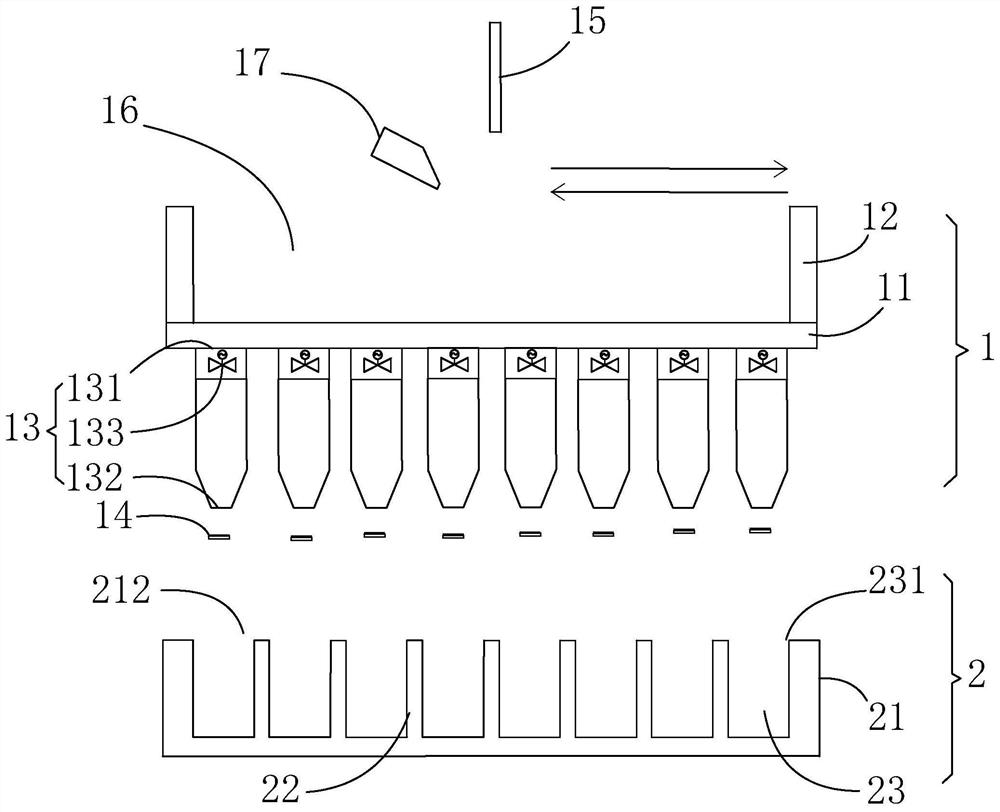

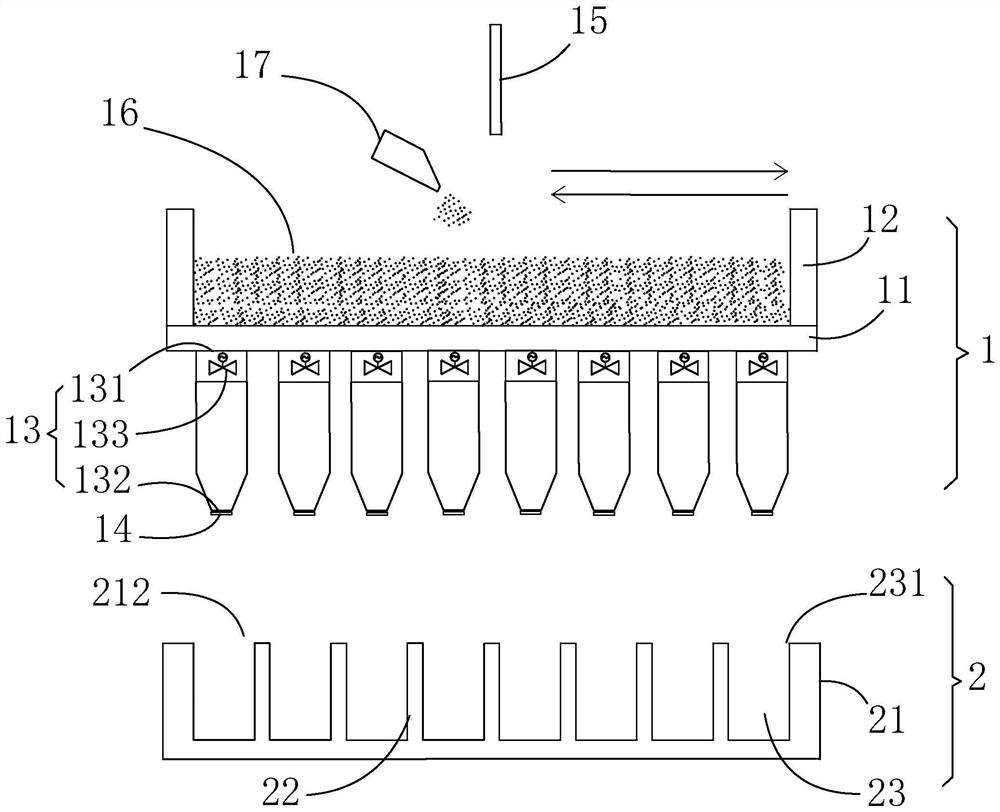

[0044] The invention provides a powder distributing device, such as figure 1 As shown in -3, the powder distribution device includes a powder distributor 1 and a mold 2, and the mold 2 is used in conjunction with the powder distributor 1.

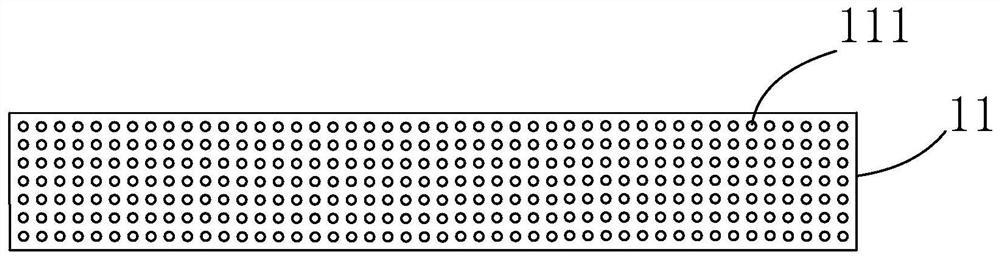

[0045] The powder distributor includes a bottom plate 11 , a side wall 12 , a powder sweeping plate 15 , at least two funnels 13 docked with the bottom plate 11 away from the storage cavity 16 , and a weighing device 14 . The side wall 12 is connected to the bottom plate 11 and forms a storage cavity 16 with it. The powder sweeping plate 15 is used to sweep powder in the storage cavity 16. The bottom plate 11 is provided with through holes 111 that are evenly distributed and run through it (as shown in FIG. 3 ). , the weighing device 14 is arranged at the outlet 132 of the funnel and corresponds to the funnel 13 one by one. Specifically, each of the weighing devices 14 is placed at the outlet of the funnel 132 and is arranged opposite to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com