Waste residue cleaning system for waste incineration electricity generation

A waste incineration and waste residue technology, which is applied in the treatment of combustion products, combustion methods, and removal of solid residues, etc., can solve the problems of substandard waste temperature and inconvenient temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

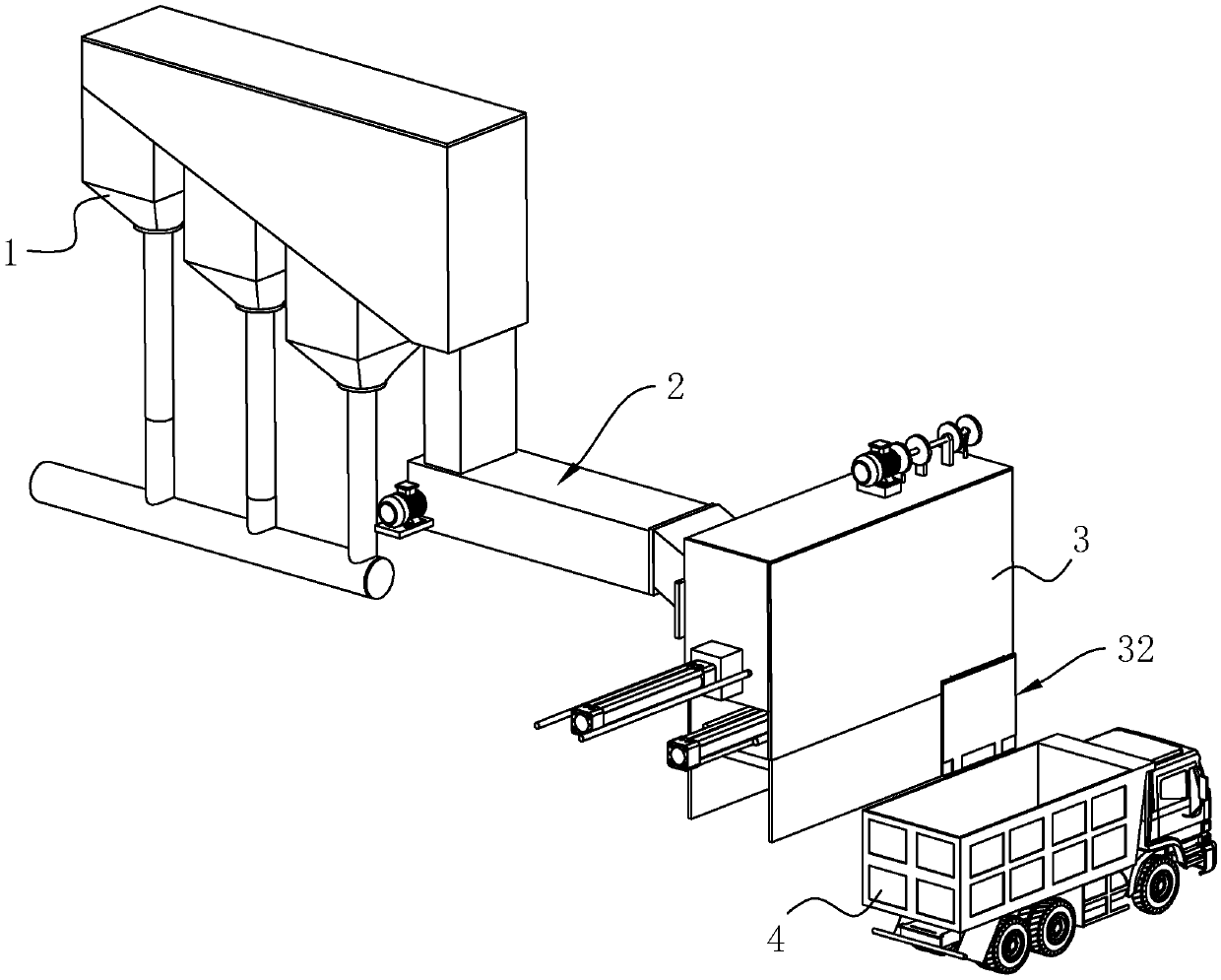

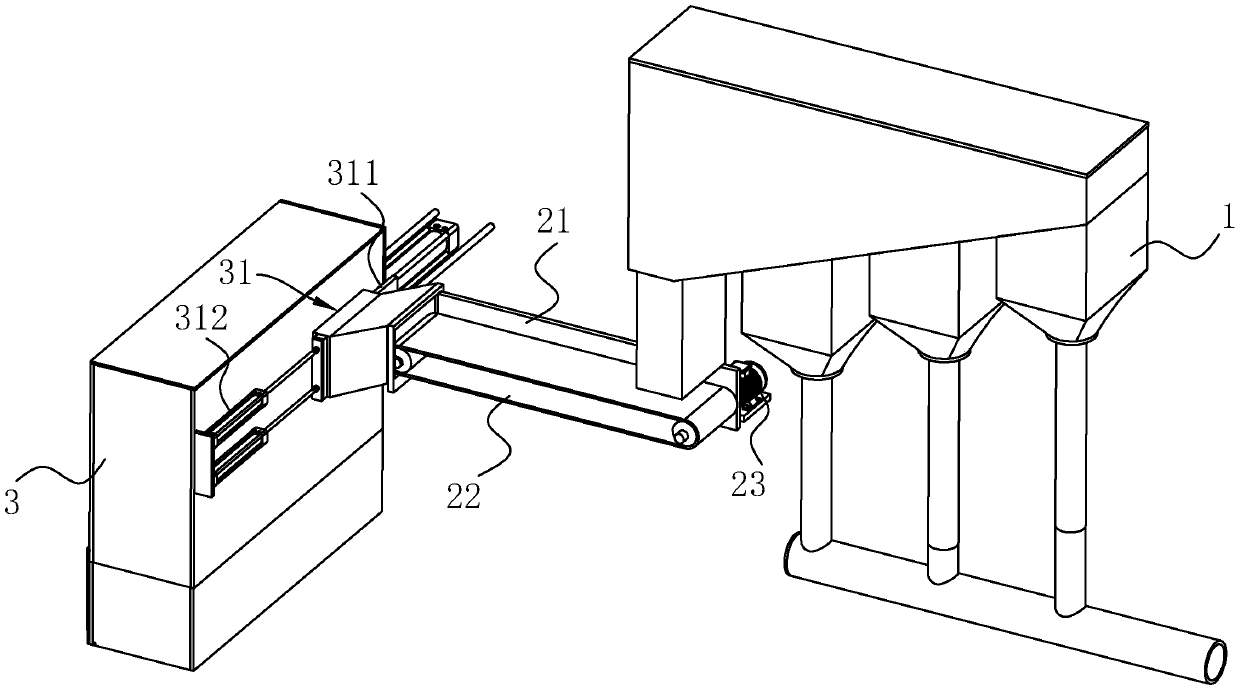

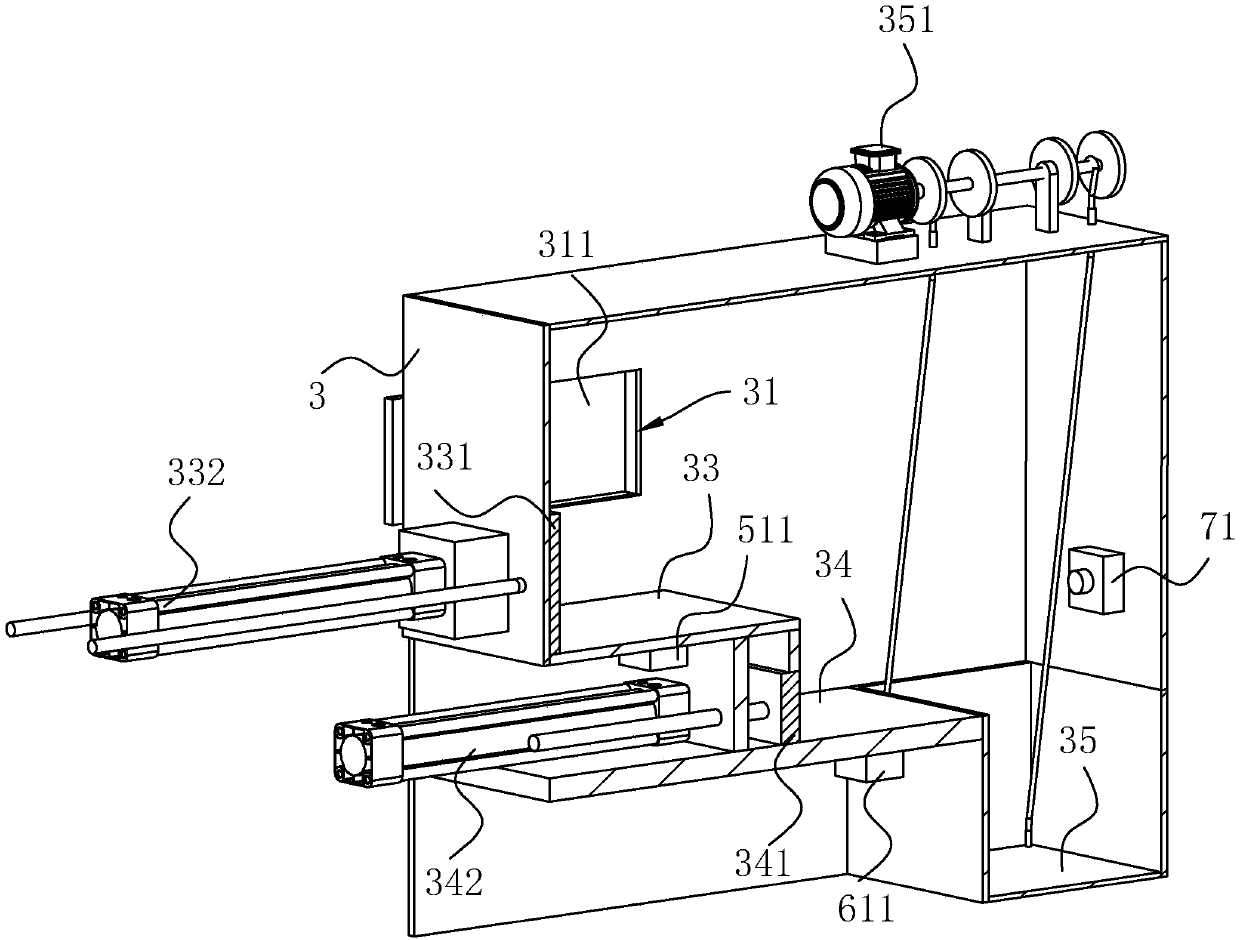

[0045] A waste residue cleaning system for waste incineration power generation, see figure 1 with figure 2 , including an incinerator 1, a conveying device 2, a slag pit 3 and a transport vehicle 4. The bottom of the incinerator 1 communicates with the end of the conveying device 2, and the end of the slag pit 3 close to the conveying device 2 is provided with a feed port 31. The feed port 31 communicates with the end of the conveying device 2 away from the incinerator 1, and the slag pit 3 is far away One side of the conveying device 2 is provided with a discharge port 32 , and the transport vehicle 4 is located below the discharge port 32 . The waste slag produced after the garbage is incinerated by the incinerator 1 enters the conveying device 2, and the conveying device 2 transports the waste slag to the slag pit 3 through the feed port 31, and the waste in the slag pit 3 finally enters the transport vehicle through the discharge port 32 4 were transported away.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com