Rotary-press processing method and device of long steel pipe with tensile

The technology of a processing device and processing method is applied in the field of spinning processing of long steel pipes with tension and its devices, which can solve various problems and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

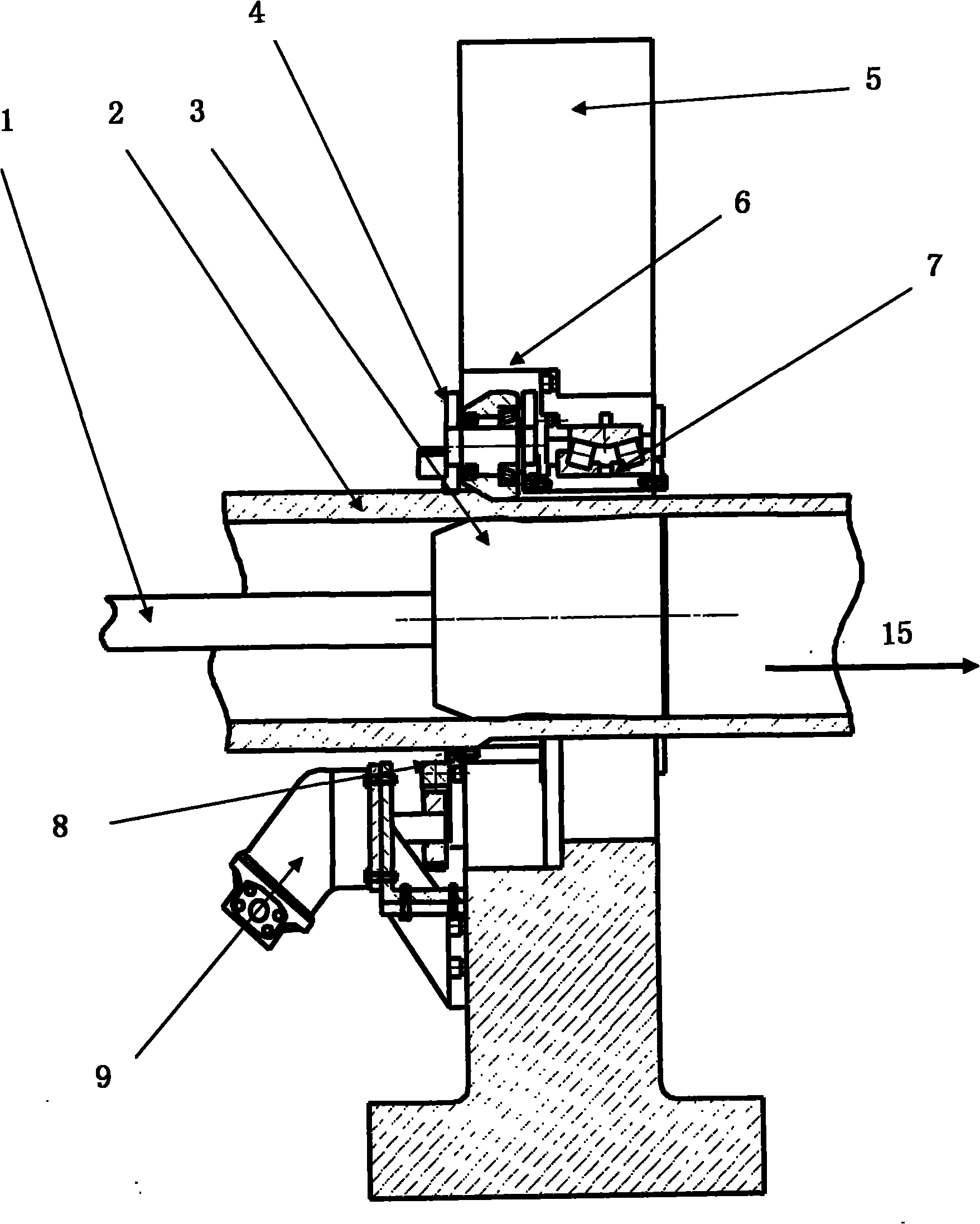

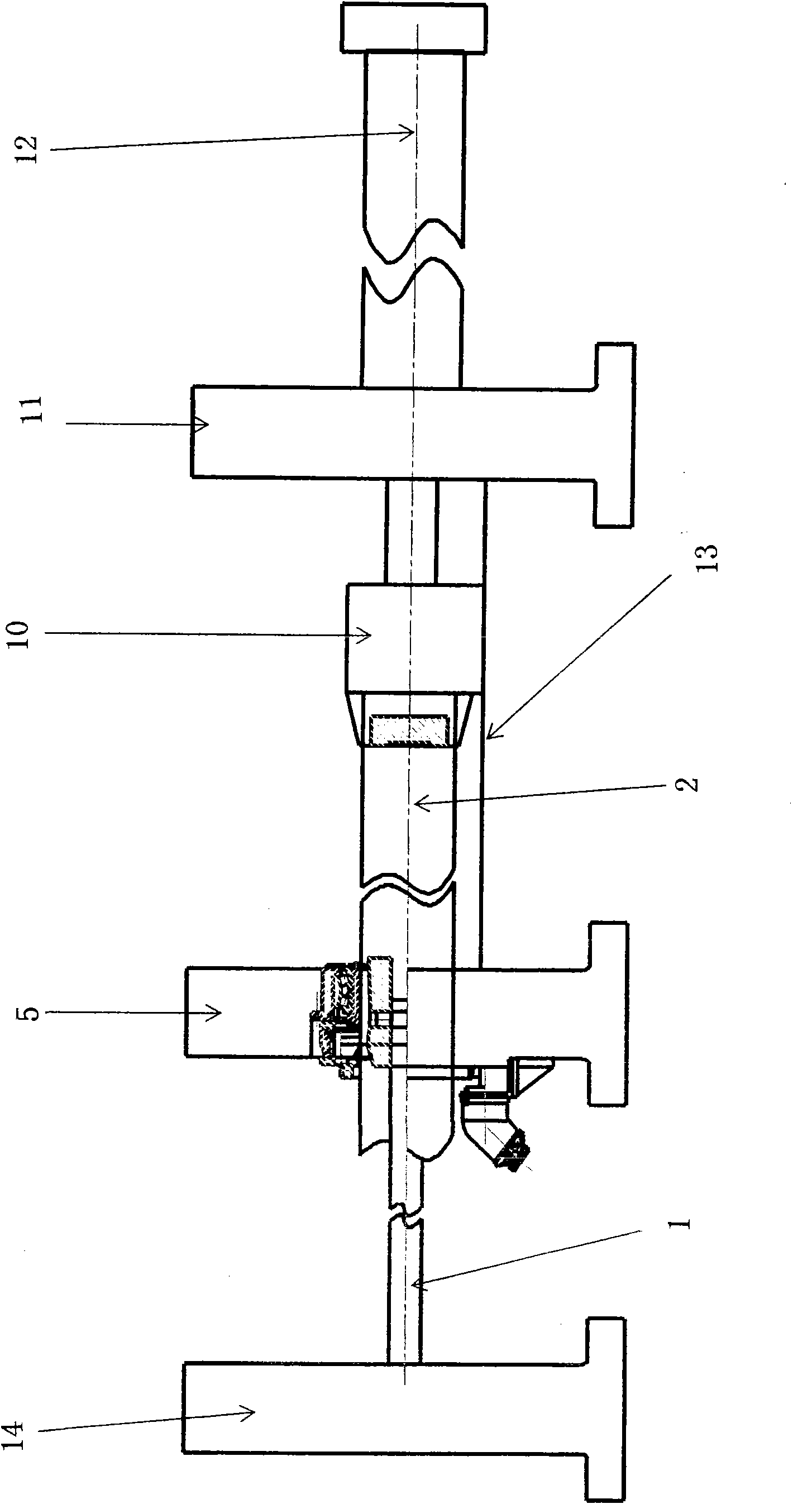

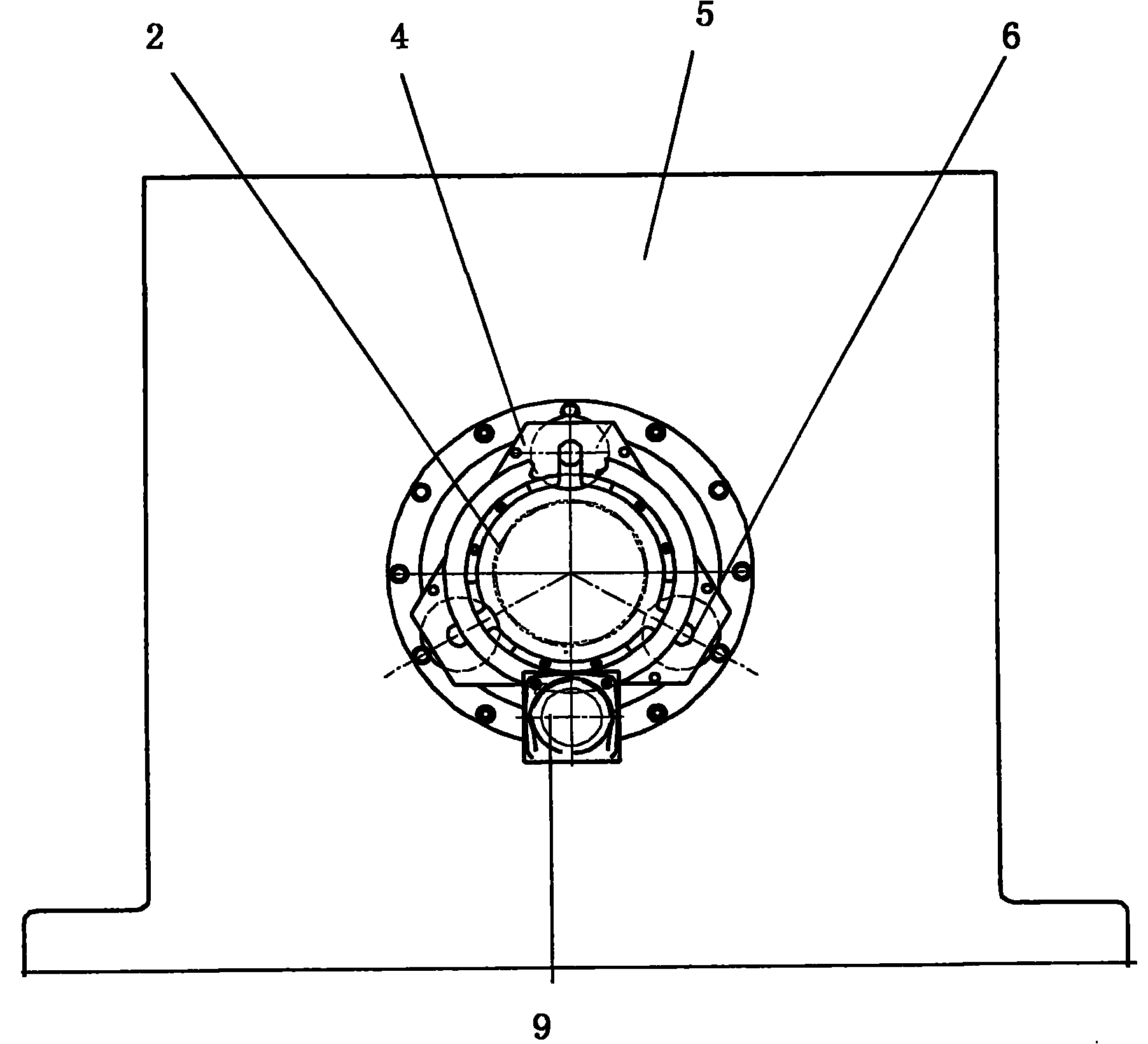

[0021] like Figure 1 ~ Figure 3 As shown, this long steel pipe spinning device with tension is composed of three frames installed on the same axis, wherein the tail frame 14 provides the fixed mandrel force, the middle frame 5 provides the rotation force, and the head frame 11 provides traction. Tension force also includes the processed steel pipe 2 and the mandrel 3 arranged inside the steel pipe 2, the outer rotating frame 4, the rotary wheel 6, and the traction chuck 10, wherein the outer rotating frame 4 is installed on the middle frame 5 of the equipment and Relying on the connection between the bearing 7 and the center frame 5, three rollers 6 with the same diameter are installed on the outer wheel frame 4 in a 120° distribution. Axis rotation, can also rotate along its own axis, the outer rotary wheel frame 4 rotates along the axis of the middle frame 5 under the power drive together with the rotary wheel 6 in the middle frame 5, and the steel pipe 2 that is to be thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com