Combined type preform taking and cooling device and method thereof

A cooling device and a combined technology, applied in the field of combined preform cooling devices, can solve the problems of preform outer surface cooling, poor shape and dimension accuracy and outer surface quality, and affect the overall quality of preforms, so as to achieve uniform cooling and improve The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

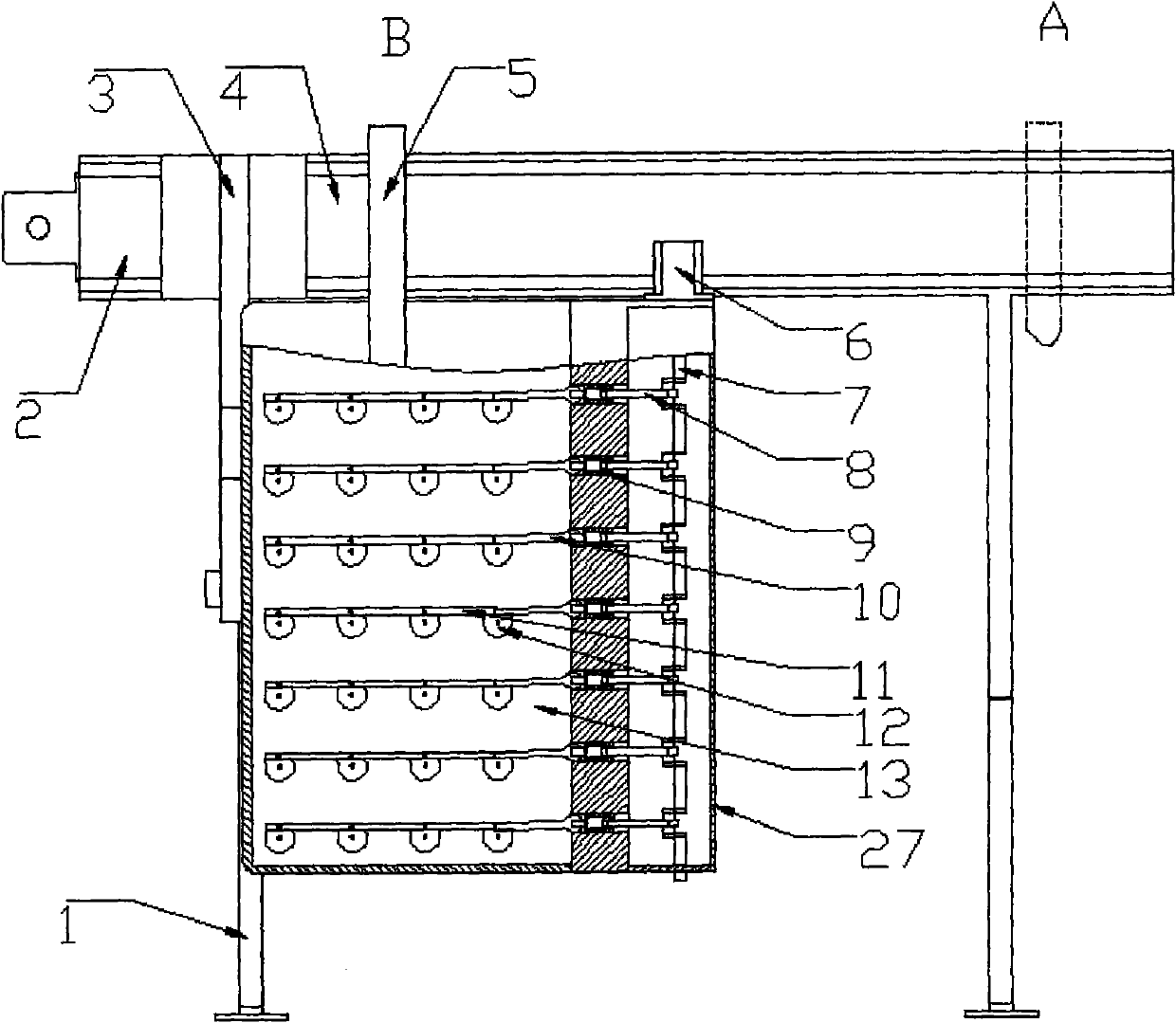

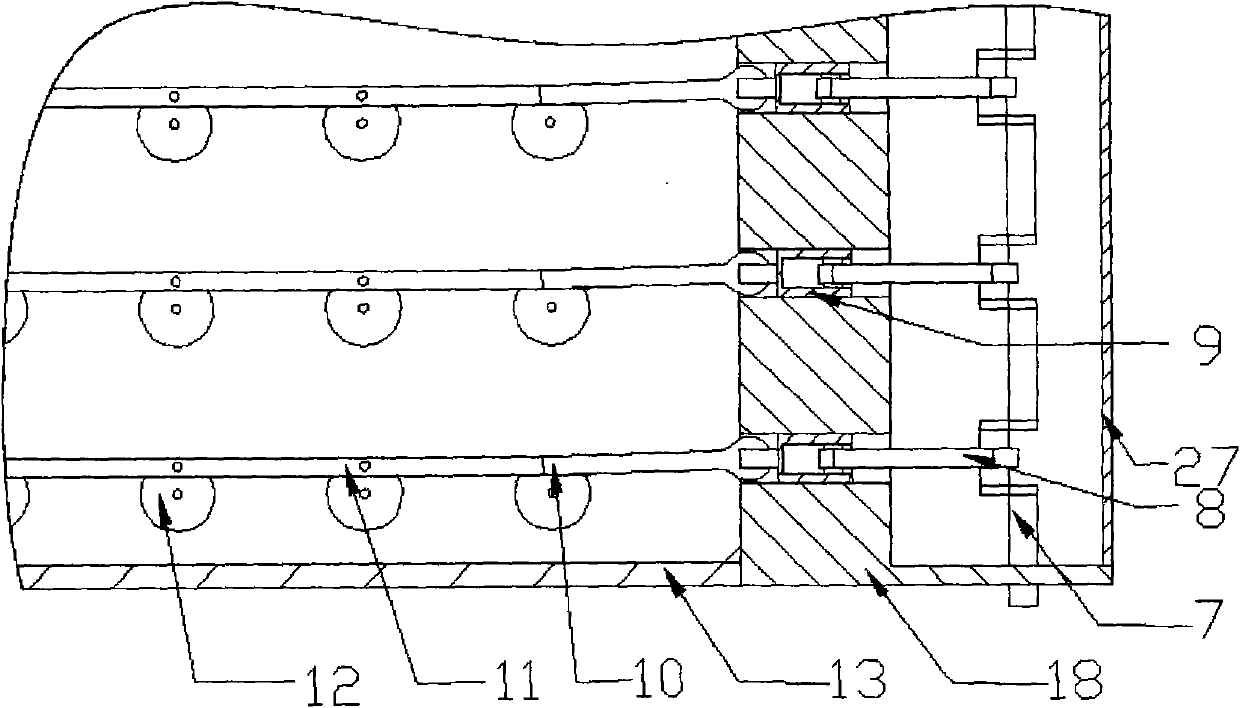

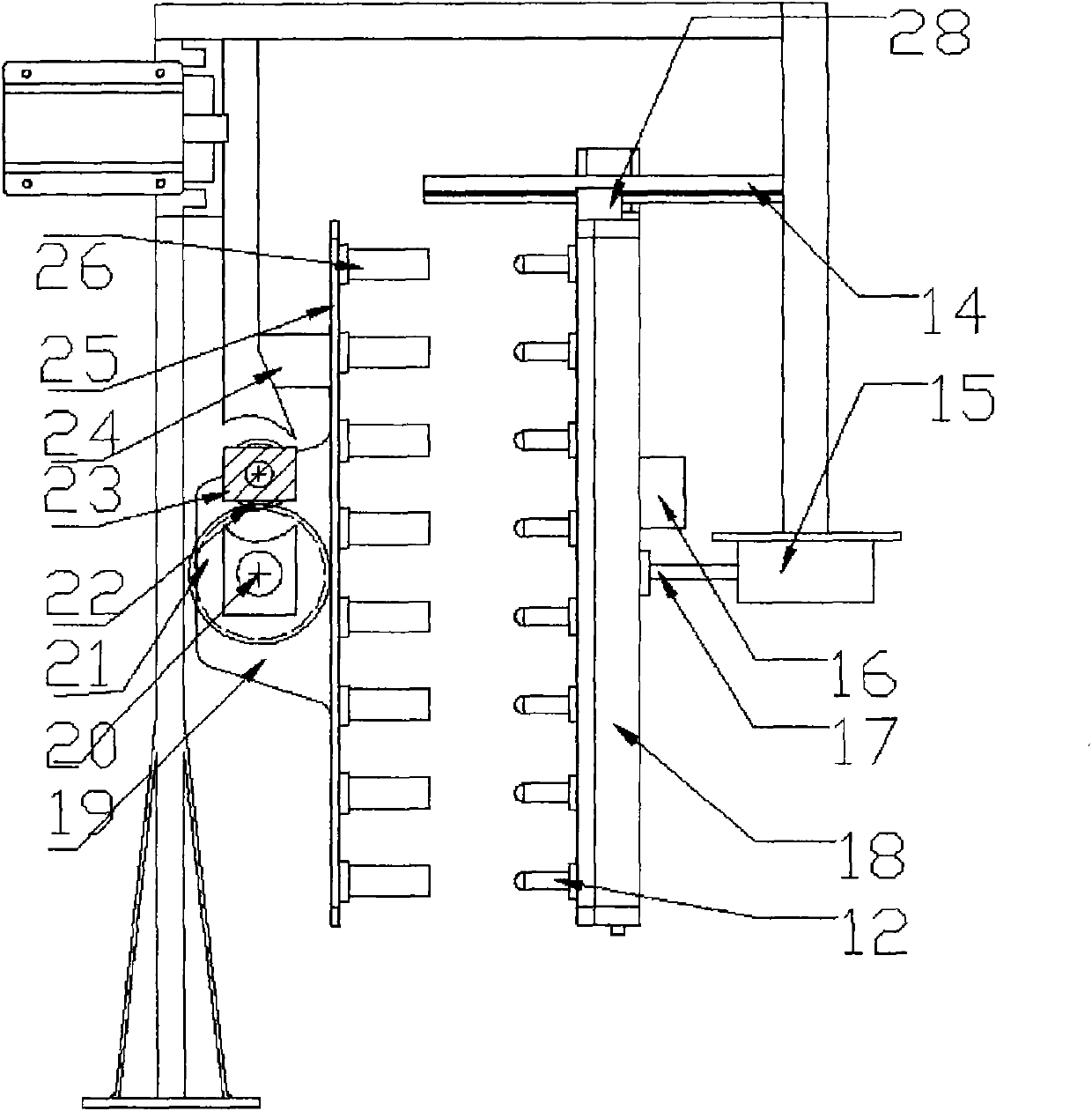

[0042] Such as Figure 1A , 1B , 2A, 2B and image 3 As shown, it is a combined preform fetching manipulator cooling device provided by the present invention, which is installed on one side of the preform injection molding machine. The preform injection molding machine has a reversible composite mold and a mold for mold opening. The mold can form multiple mold cavities when the mold is closed, and after the plastic melt is injected into the mold cavity and after a certain molding time, multiple preforms are formed, which are taken away by the manipulator device of the present invention after the mold is opened. The manipulator device is mainly composed of a translation device and a cooling tube cooling device, wherein: the translation device includes a servo motor 2, a frame 1, a linear guide rail 4 and a sliding table 3, etc., and the sliding table 3 can reciprocate along the linear guide rail 4. Among them, Position A is in the mold and position B is the starting position. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com