Multi-layer co-extrusion film-blowing die head capable of automatically controlling and stabilizing diameter of female film

A multi-layer co-extrusion and parent film technology, which is applied in the field of extrusion blown film equipment, can solve the problems of difficult adjustment, large die diameter, and large surface area, and achieve reduced heat dissipation, reduced diameter, and reduced cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

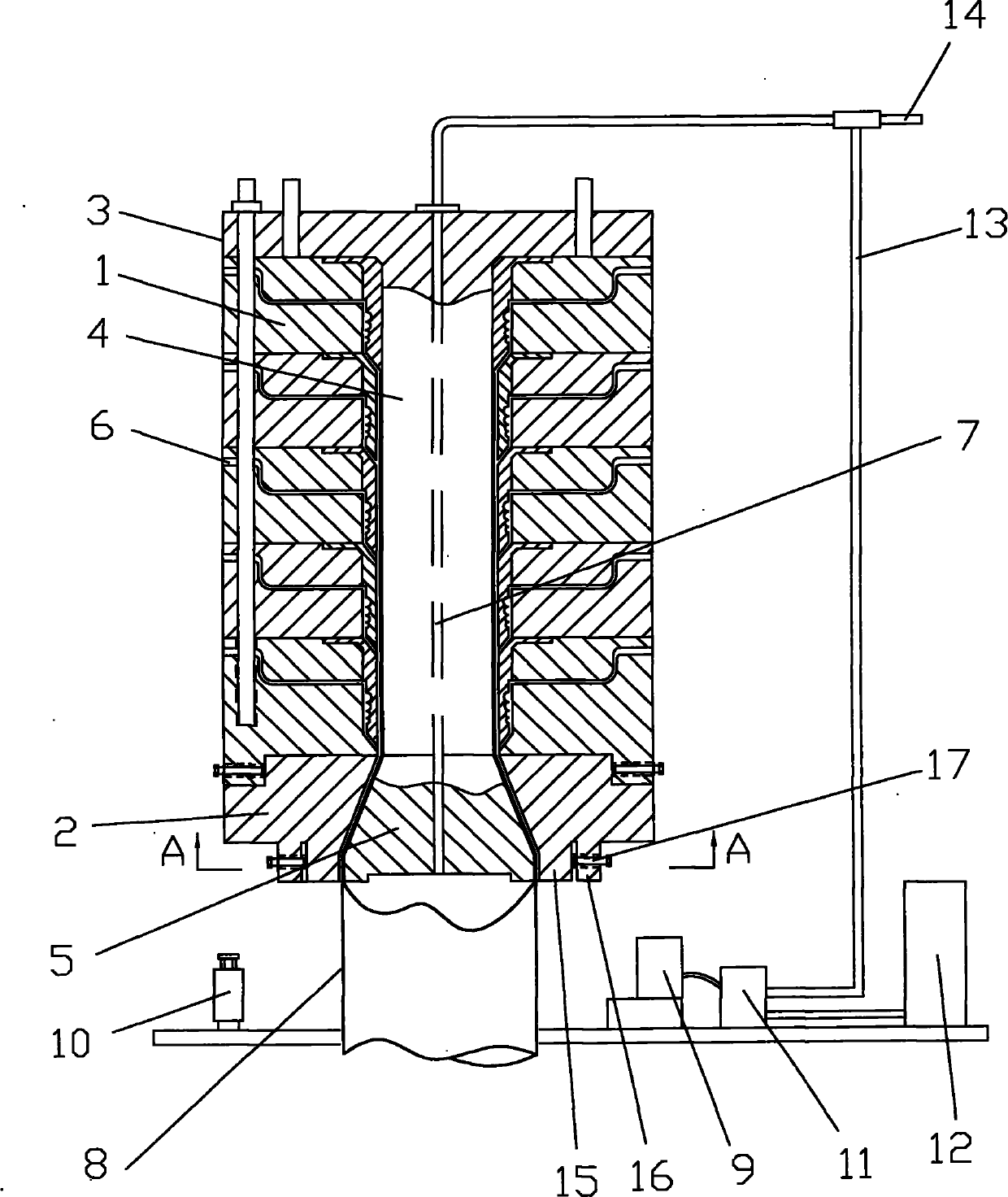

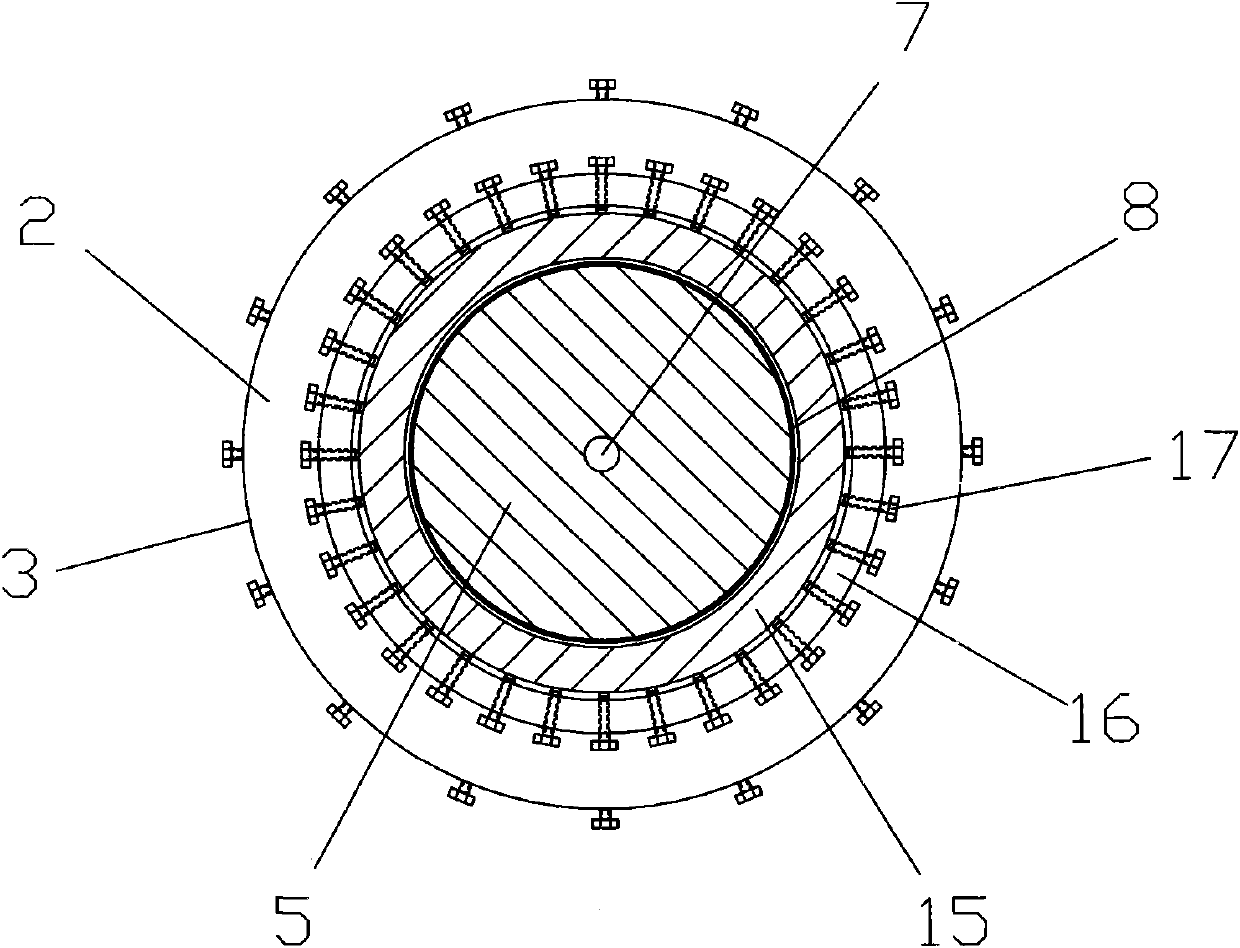

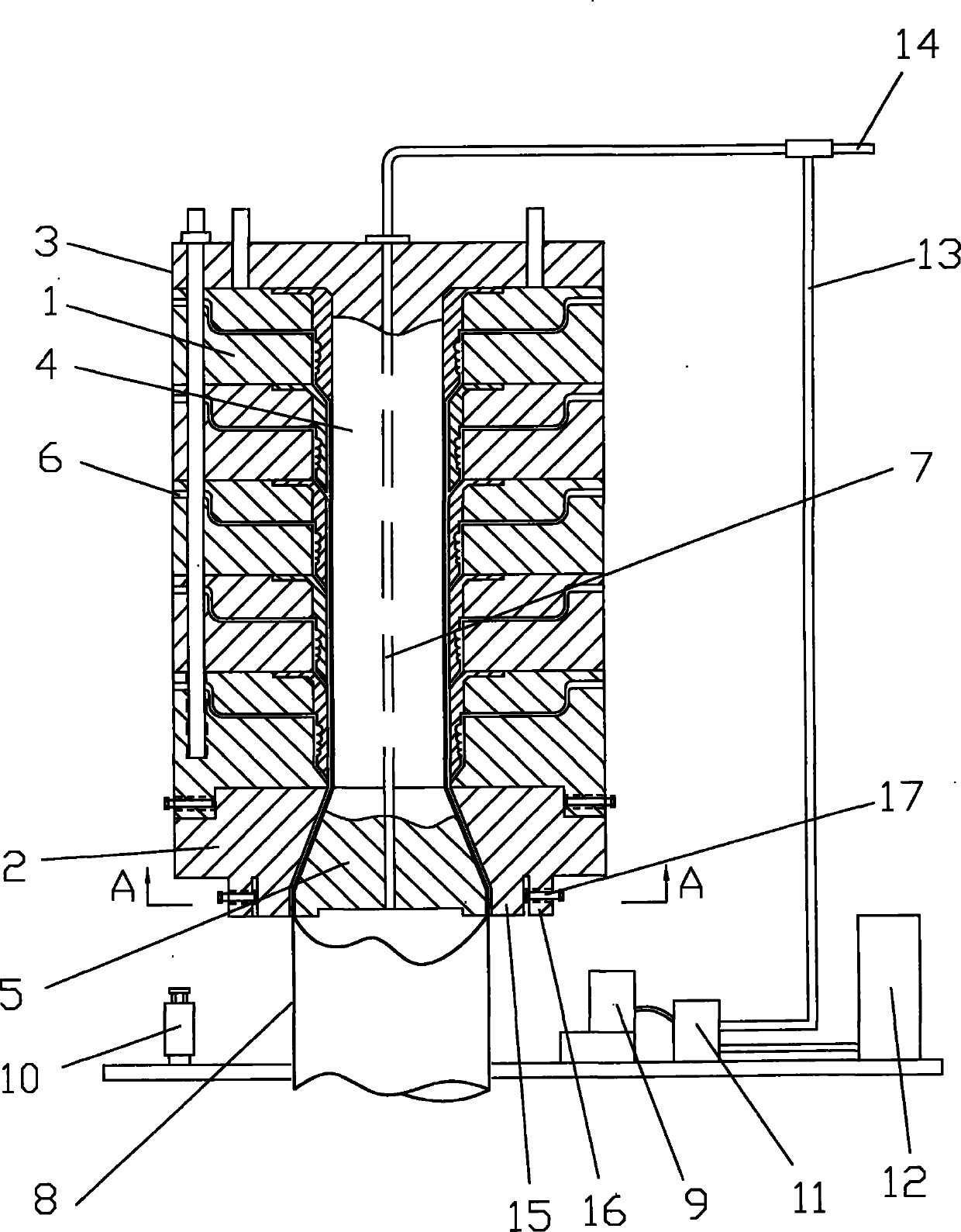

[0012] by Figure 1-2 Shown is an embodiment of the present invention, which includes a mold body 3 composed of a multi-layer die head 1, a die 2, a core rod 4, a die core rod 5, a runner 6 in the die head 1, and air intake and exhaust Hole 7; the phantom 3 is equipped with an infrared probe 9 for detecting against the mother film 8, an infrared reflector 10 for receiving and reflecting infrared, the infrared probe 9 is connected with a solenoid valve 11, and the solenoid valve 11 is connected with an air pump 12 and an air pipe 13 is connected, the inlet and exhaust ducts 7 are connected with the air pipe 13 and the exhaust pipe 14; the inner wall of the die 2 is in the shape of a trumpet with a small upper diameter and a large diameter, and the die core 5 matched with the die 2, its outer wall The upper diameter is small and the lower diameter is large; there are two rings at the bottom of the die 2. The inner ring is the die opening adjustment ring 15, and the outer ring 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com