Road guard rail and building method thereof

A road and guardrail technology, applied in the directions of roads, roads, road safety devices, etc., can solve the problems that the elastic characteristics of waste tires cannot be fully utilized, vehicle losses and casualties are high, construction costs and maintenance costs are high, and it can improve the guiding performance. Good, simple construction, short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

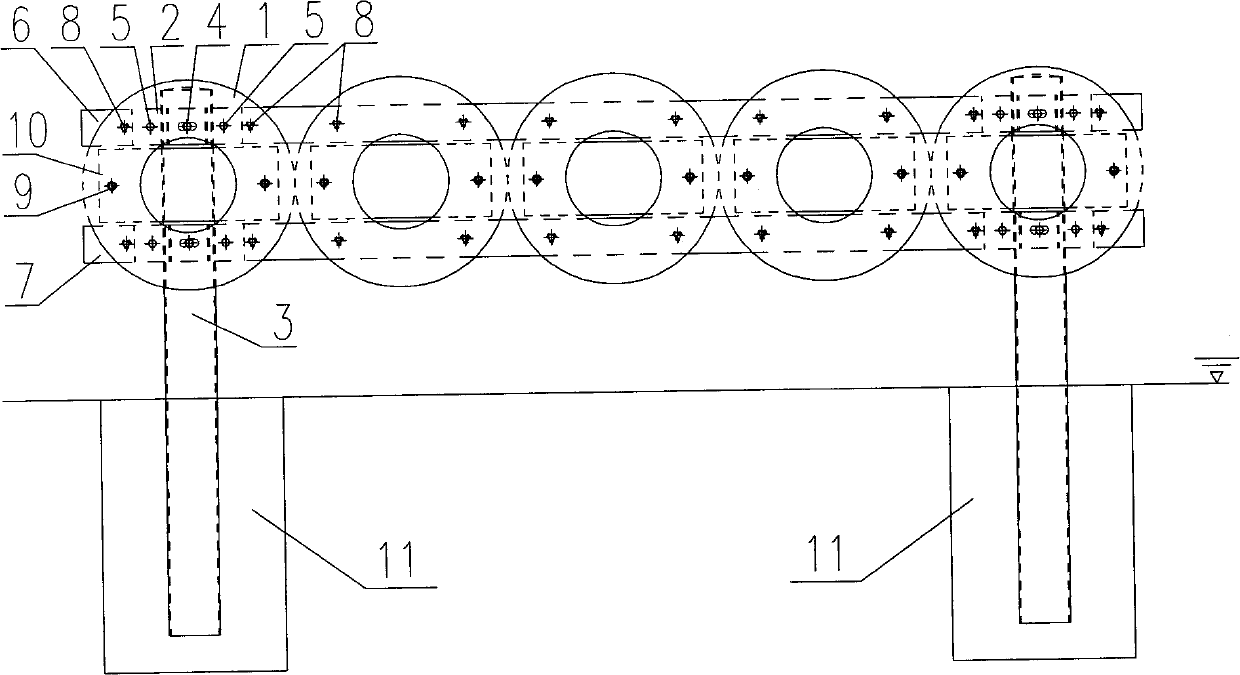

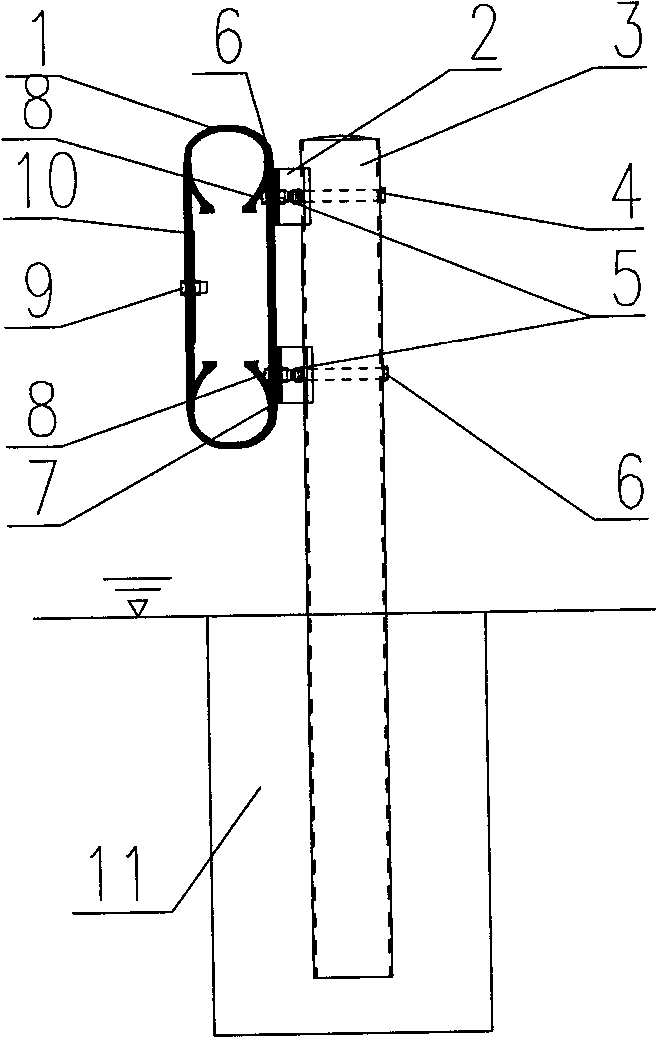

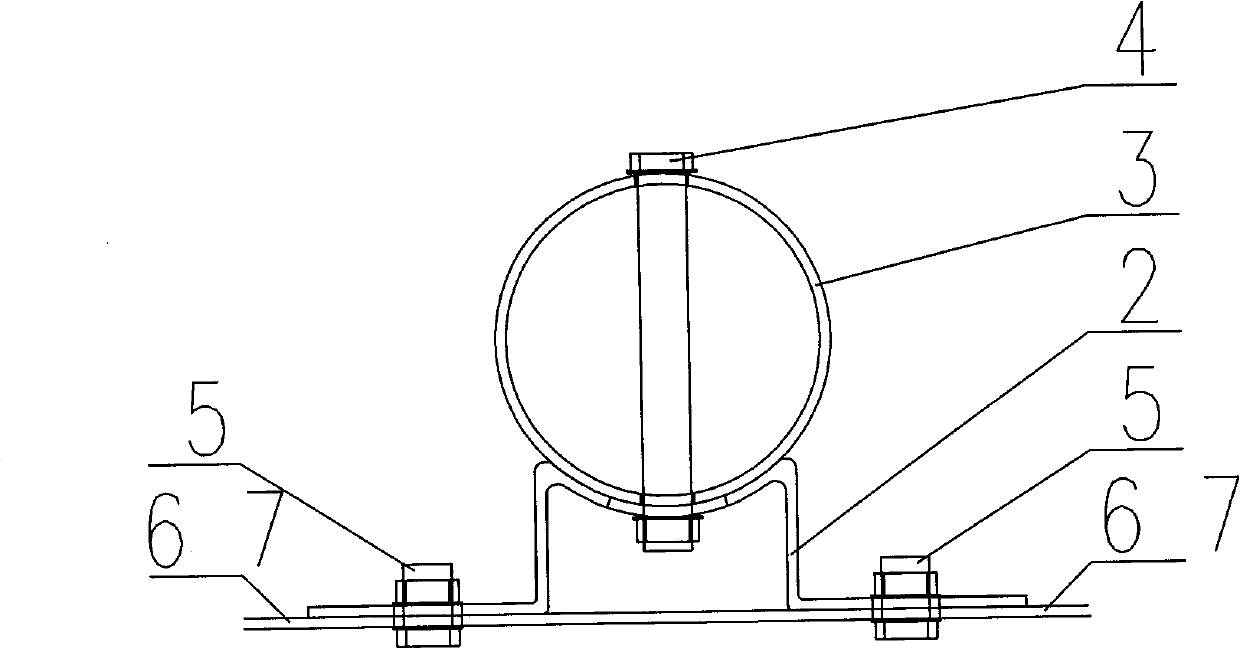

[0030] see figure 1 , figure 2 with image 3 , a kind of road guardrail, comprise the column 3 that is arranged on the ground at intervals, the column 3 bottom is fixed in the concrete foundation 11 of road surface, the column 3 top is fixed on the bracket 2 by bolt 14, the column 3 is preferably a cylinder, the bracket 2 It has an arc-shaped part matched with the outer circular surface of the column 3. The bracket 2 is fixed on the upper and lower beams 6, 7 by bolts II 5, and the upper and lower beams 6, 7 are arranged between the two columns 3. The side of the lower crossbeam 6, 7 facing the road is fixed side by side with a plurality of waste tires 1 by bolts III 8 in turn, and the tires 1 are placed vertically, see Figure 4 The side of the tire 1 facing away from the road is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com