Retaining wall reinforcement material produced by waste tires

A technology for reinforced materials and waste tires, applied in the field of reinforced materials, can solve the problems of easy breeding of mosquitoes, flies and bacteria, spread diseases, endanger human health and other problems, achieve convenient production and laying, increase the scope of influence and increase the scope of influence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

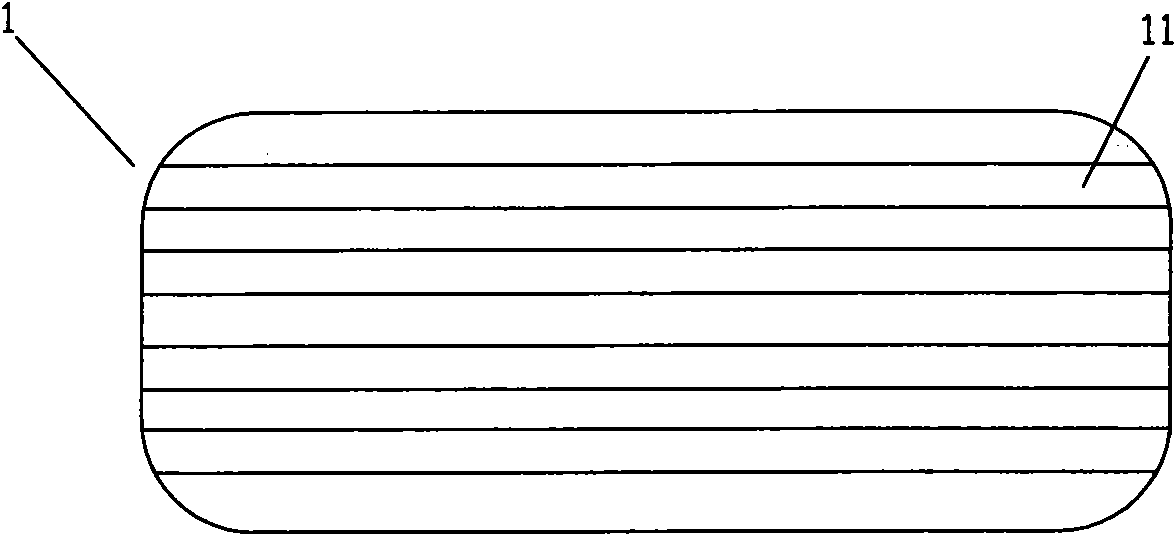

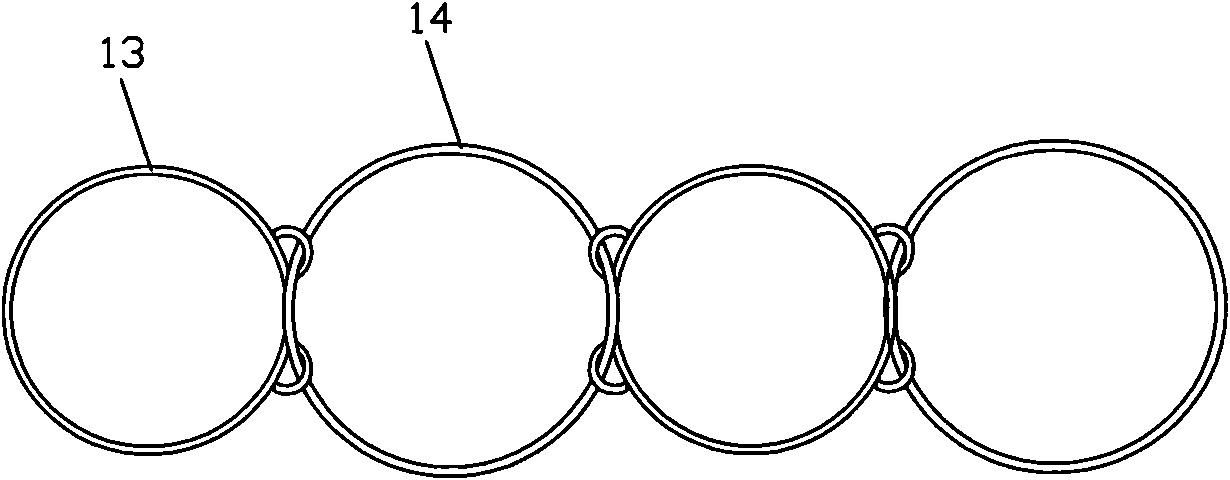

[0022] Such as figure 1 As shown, the retaining wall reinforcement material of the present invention uses the annular rubber ring 11 or rubber strip cut radially along the waste tire 1 as the basic component, and the retaining wall reinforcement is made by connecting several basic components to each other. Material. Such as image 3 As shown, the reinforcing material is a strip structure formed by connecting several annular rubber rings 13 and 14 in turn, and two adjacent rubber rings are connected to each other in the form of loop buckles. Such as Figure 5 shown by image 3 After wrapping the ring-shaped rubber ring in the form, the reinforced material naturally forms a three-dimensional structure of convex and concave in a free state, and is embedded in the soil in a free state, which can increase the influence range of the soil in the thickness direction. Among the adjacent annular rubber rings, the same piece of reinforced material can be made of annular rubber rings ...

Embodiment 2

[0024] Such as Figure 4 As shown, the reinforced material of the present invention is another scheme in which several annular rubber rings 13 are connected in the form of loop buckles. First, one annular rubber ring is flattened, and then one end of the other annular rubber ring is passed through the annular rubber ring and then folded in half along the radial direction of the other annular rubber ring, and so on, to form the reinforced material structure in the figure. Compared with the reinforcing material in embodiment 1, this embodiment only has a change in the way of winding the rubber rings, and other structures are the same as in embodiment 1.

Embodiment 3

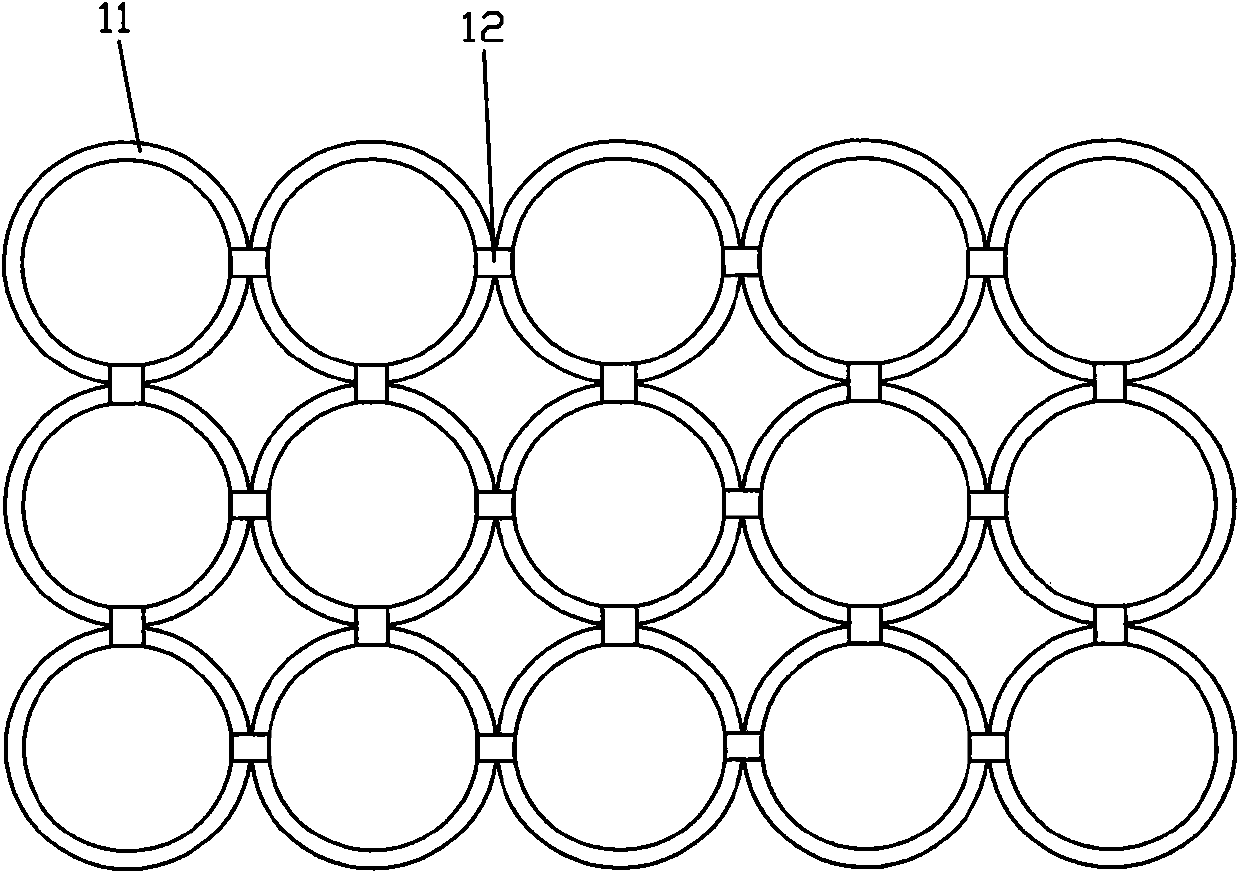

[0026] Such as figure 2 As shown, the reinforced material in this embodiment is a network structure formed by connecting several annular rubber rings 11 to each other, and the adjacent annular rubber rings are connected by fasteners 12. In addition, the rubber rings can also be Use the adhesive and / or looper methods mentioned in Examples 1 and 2 to connect. If the looper button is used to connect, in order to ensure the convenience of implementation, the annular rubber rings in each row or column of the mesh structure are connected in pairs in the form of a looper button, and the corresponding positions between adjacent rows or adjacent columns The annular rubber rings are bonded or connected to each other by fasteners.

[0027] During the construction process, one end of the reinforced material is connected to the retaining block in a conventional way, and the other end of the reinforced material is stretched to ensure a smooth mesh structure. After filling the cavity in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com