Ultrasonic liquid level meter owning gas sound speed real-time correction

An ultrasonic and speed of sound technology, applied in the field of liquid level measurement, can solve the problems of high cost of use, difficult to meet the requirements of precision, and complex measuring devices, to simplify the difficulty of on-site installation and instrument maintenance, solve the problem of accuracy stability, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

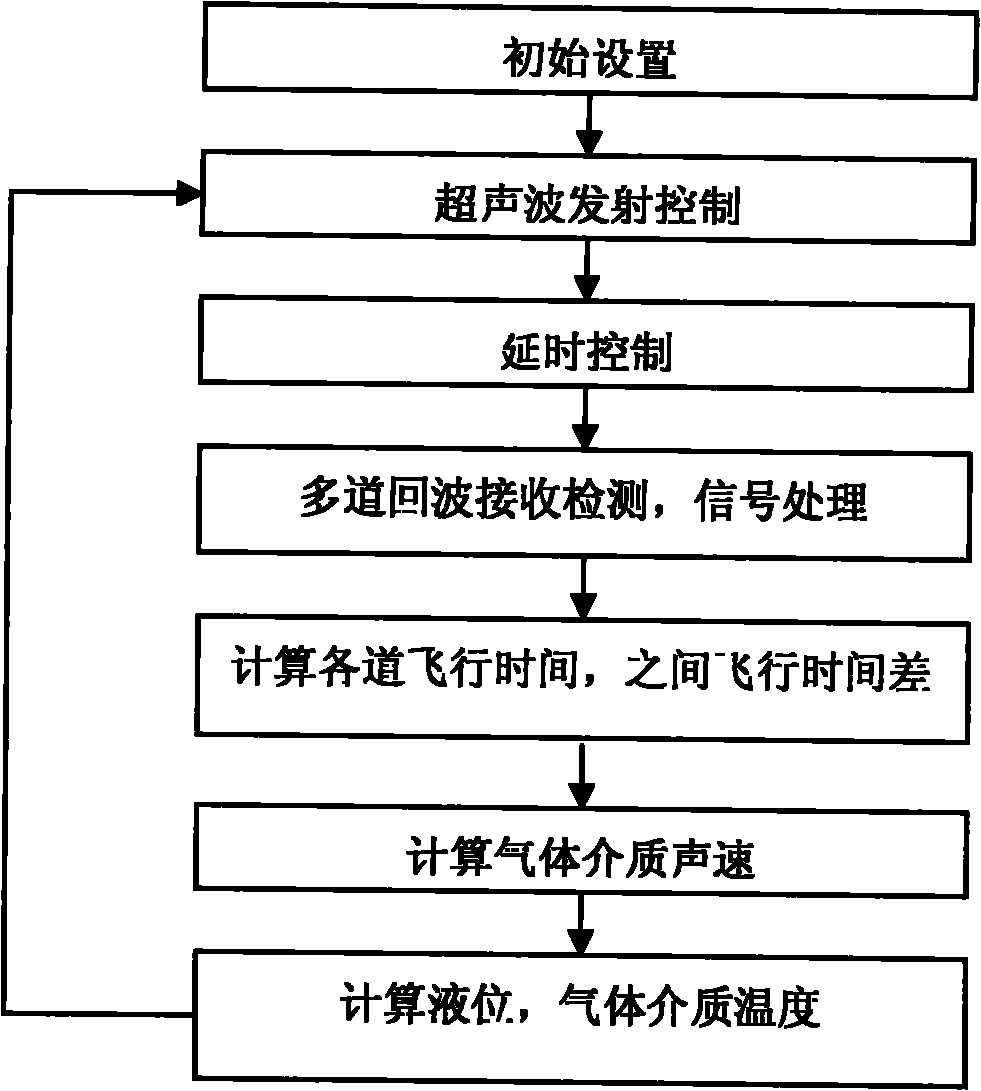

Method used

Image

Examples

Embodiment 1

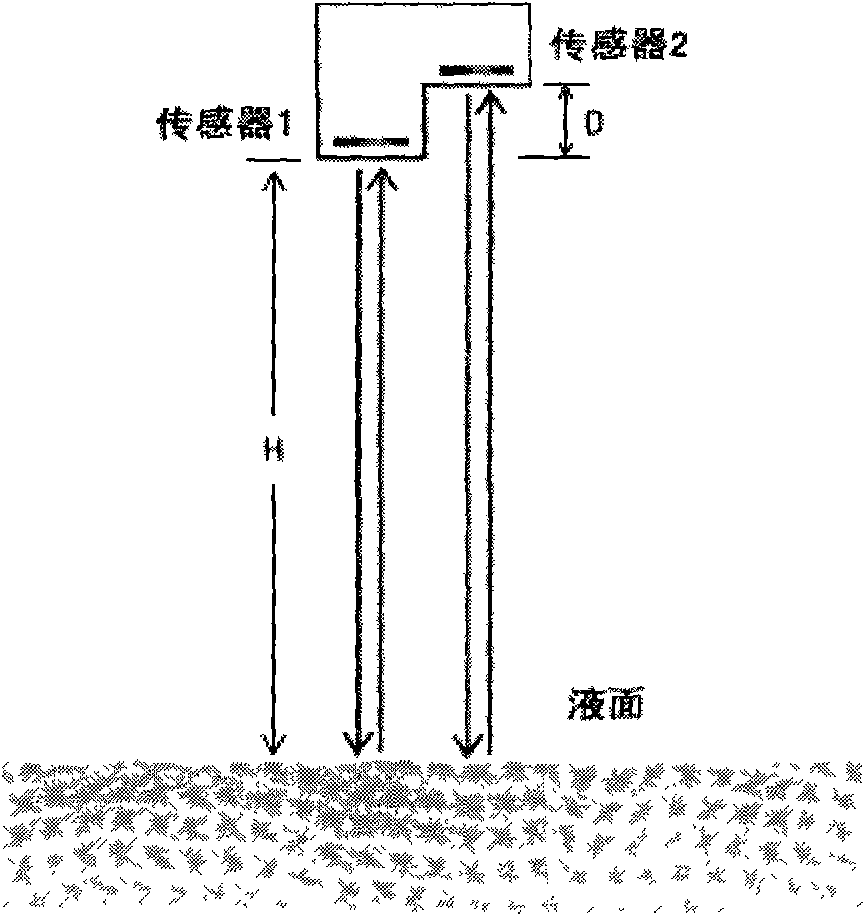

[0050] Such as figure 1 As shown, two ultrasonic sensors are used, and a fixed height difference D is staggered between them. Assuming that the gas sound velocity C and the liquid level height H are unknown quantities, the time-of-flight T1 of the sound wave of the sensor 1 in the gas and the time of flight of the sensor 2 The flight time T2 of the sound wave in the gas, according to the relationship between the flight time flight distance and the speed of sound, the following equations can be obtained:

[0051] T1=2*H / C

[0052] T2=(2*H+2*D) / C

[0053] Time difference between two beams of sound waves:

[0054] DT=T2-T1=2*D / C

[0055] This gives the speed of sound and the height of the liquid level:

[0056] C=2*D / DT

[0057] H=C*T1 / 2

[0058] If two ultrasonic sensors transmit signals at the same time, DT can be directly obtained by correlating the two received signals. This method is much more accurate than the method using the difference between T1 and T2, and is less...

Embodiment 2

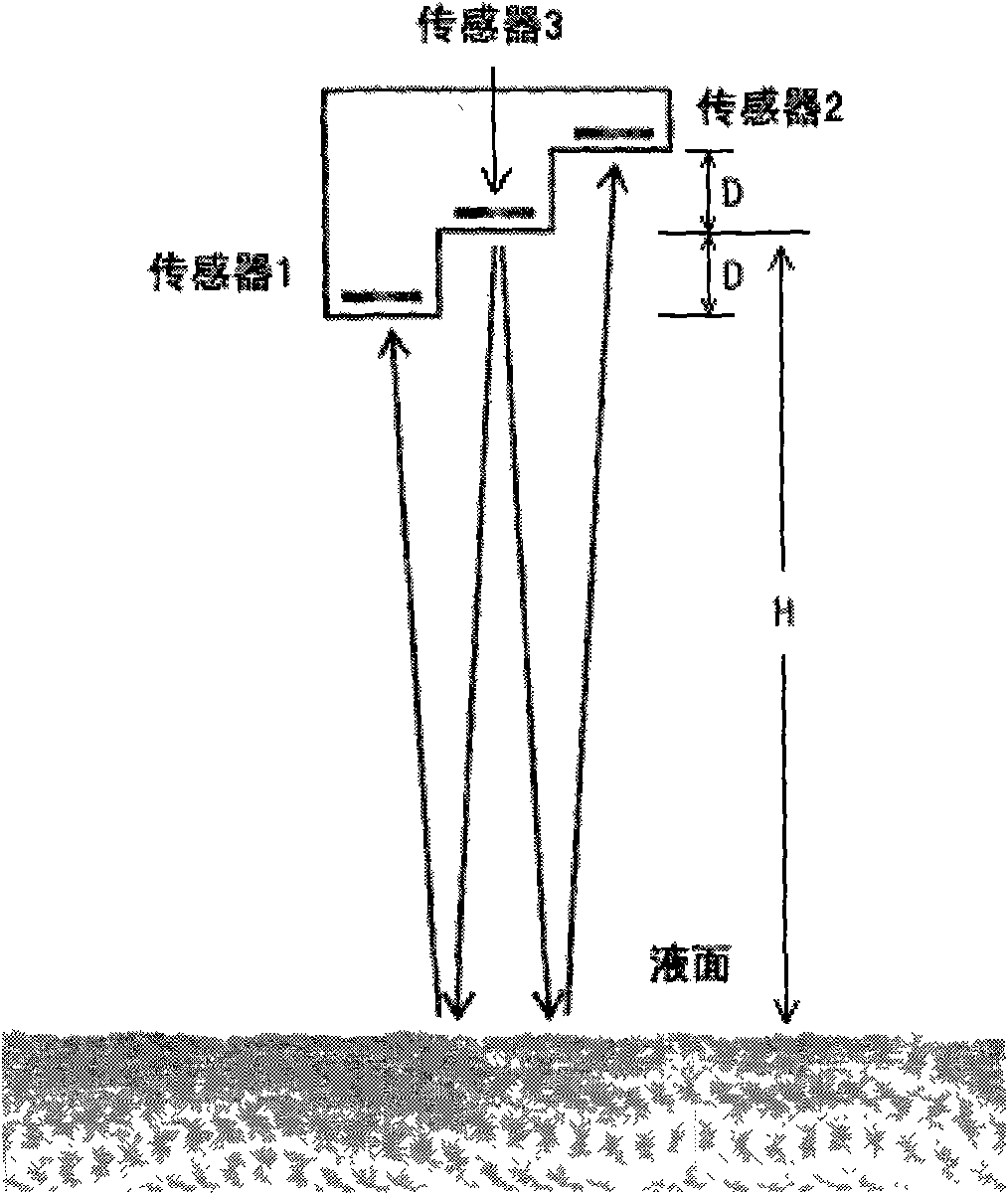

[0070] Such as figure 2 As shown, three ultrasonic sensors are used, one ultrasonic transmitting sensor and two receiving sensors. Each of the sensors 1 to 3 is staggered by a fixed height difference D, assuming that the gas sound velocity C and the liquid level height H are unknown quantities, and the sound wave flight time T1 from sensor 3 to sensor 1 and the sound wave from sensor 3 to sensor 2 are measured The flight time T2, according to the relationship between the flight time flight distance and the speed of sound, the following equations can be obtained:

[0071] T1=(2*H-2*D) / C

[0072] T2=(2*H+2*D) / C

[0073] Time difference between two beams of sound waves:

[0074] DT=T2-T1=4*D / C

[0075] This gives the speed of sound and the height of the liquid level:

[0076] C=4*D / DT

[0077] H=C*(T1+T2) / 2

[0078] The source of the two received signals using a fixed ultrasonic transmitting sensor is exactly the same, so that it can be obtained directly through correlati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com