Automatic transmission device for reshipping quartz boat

An automatic transmission and lifting device technology, applied in the direction of transportation and packaging, conveyor objects, sustainable manufacturing/processing, etc., can solve the problems of affecting the range of moving activities, low efficiency, poor reliability, etc., and achieve fast and fast transmission positioning control Ease of transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

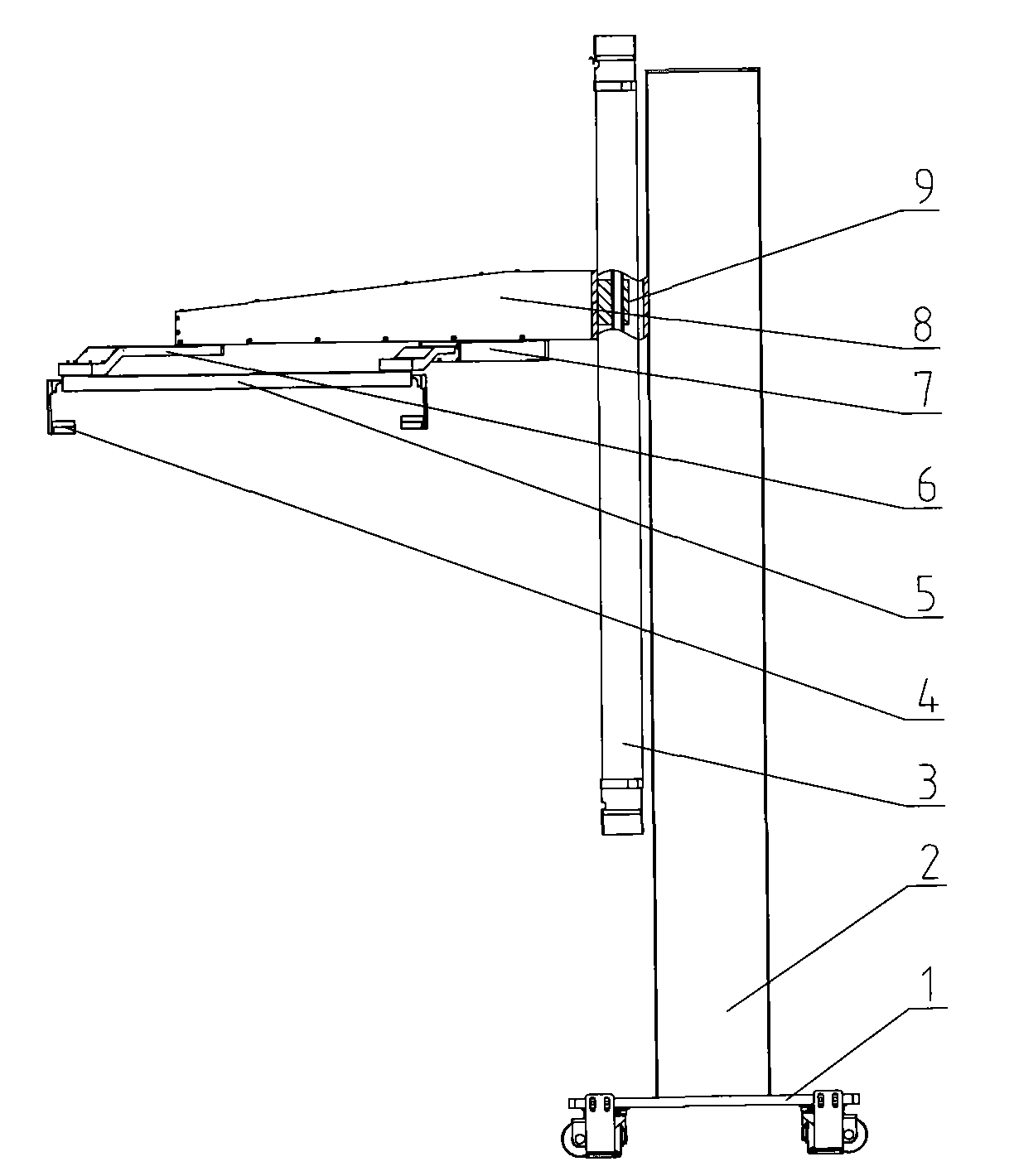

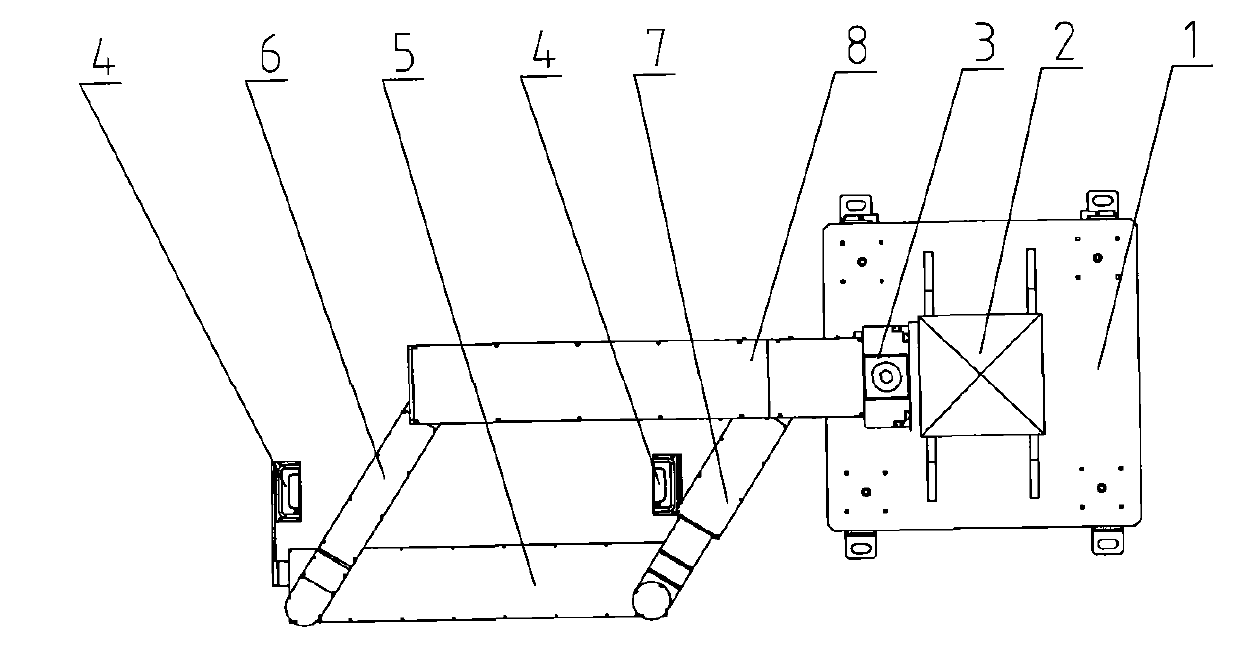

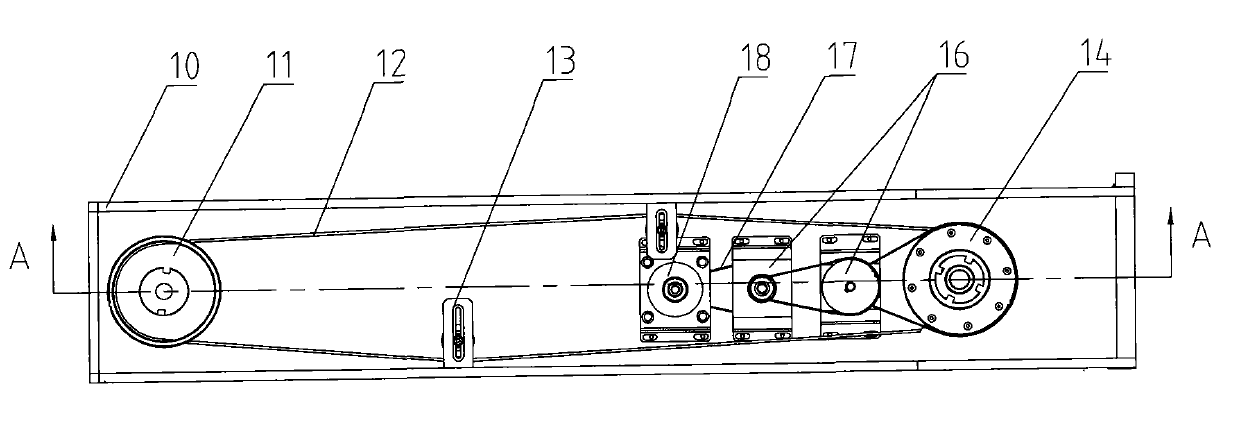

[0027] according to Figure 1-8 The specific structure of the present invention will be described in detail. The automatic transfer device for reloading the quartz boat includes a frame 2 with a lifting device 3, a lifting arm 8, an active rotating arm 7, a passive rotating arm 6, a grabbing mechanism 5, and an electrical control device. Wherein the frame 2 is fixed on the base 1 with rollers.

[0028]Utilize the nut 9 assembled on the screw rod of the lifting device 3 of the frame 2 to fix the lifting arm 8 . The lifting device 3 drives the nut of the lifting arm to reciprocate up and down in the vertical direction of the frame 2 through the motor-driven screw rod, and moves up and down along the lifting device slide rail. The sensor on the lifting device 3 in the electrical control device is used for position feedback, which can realize precise control of the rising and falling positions. The common lifting device 3 with this simple structure is adopted, which is easy to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com