Eccentric gear-noncircular gear planetary gear train vegetable pot seedling automatic transplanting mechanism

The technology of non-circular gear and eccentric gear is applied in the field of eccentric gear-non-circular gear planetary gear system automatic planting mechanism for vegetable pot seedlings, which can solve the problems of missing seedlings, increased seedling shortage rate, low work efficiency, etc. The effect of improving efficiency, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

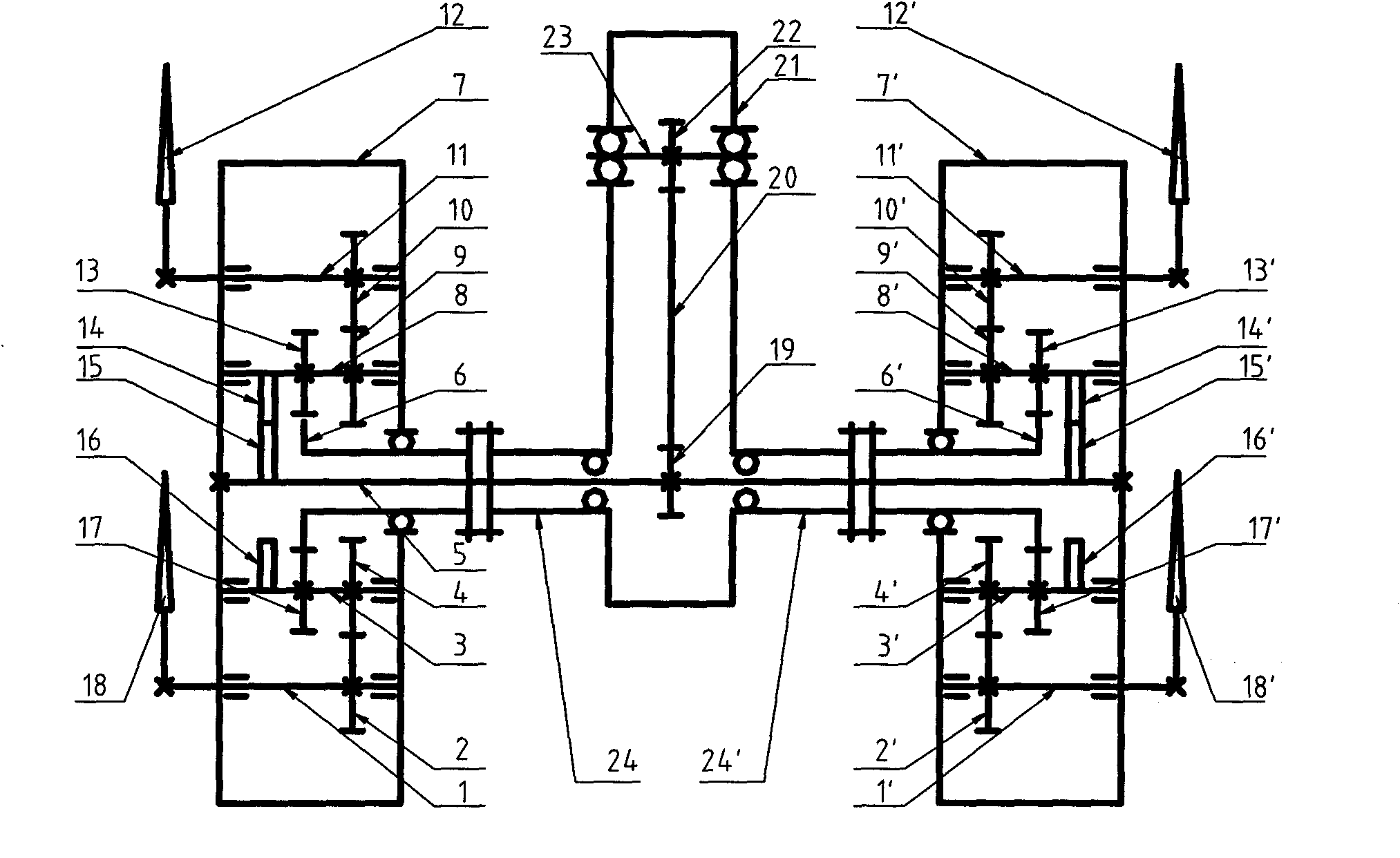

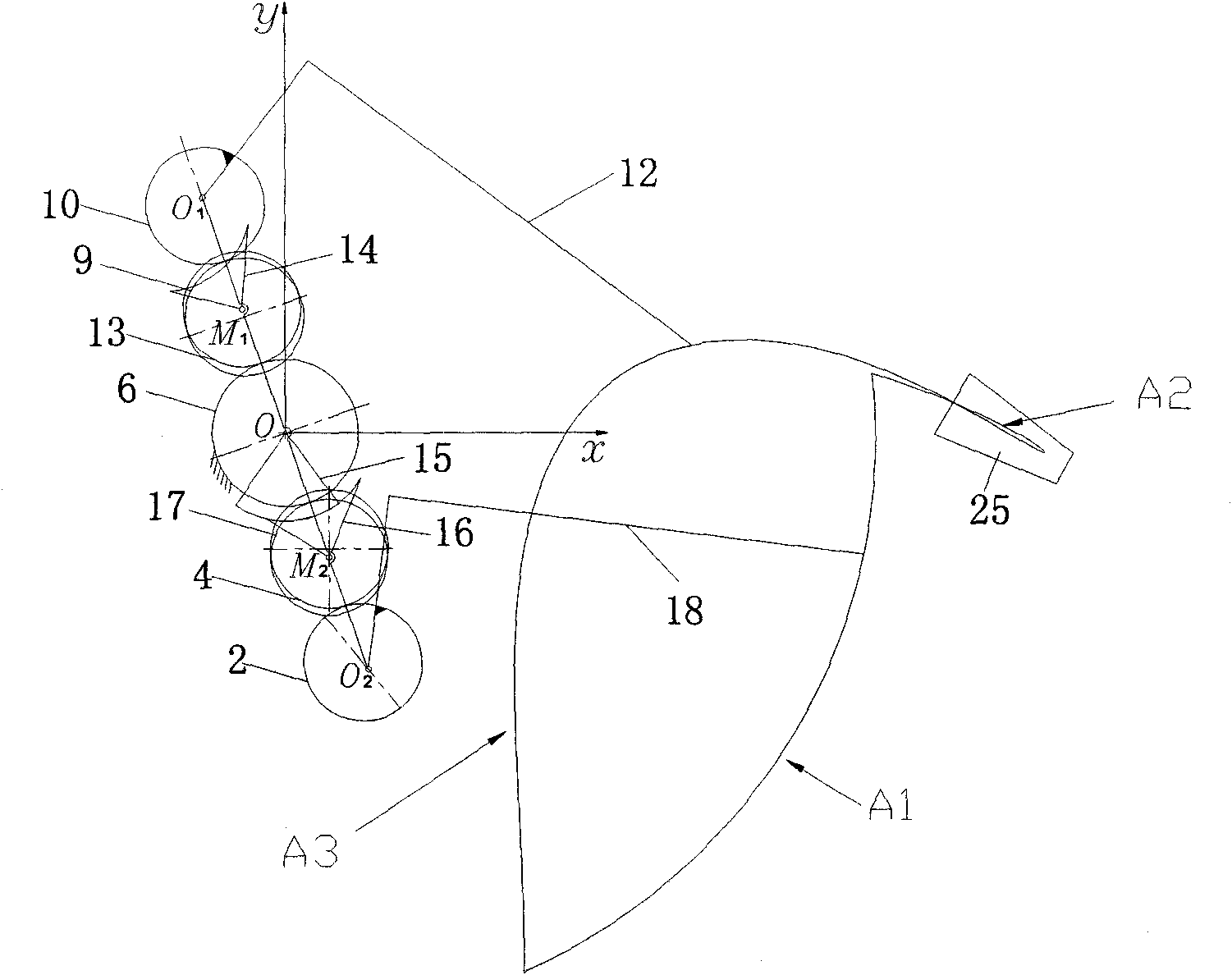

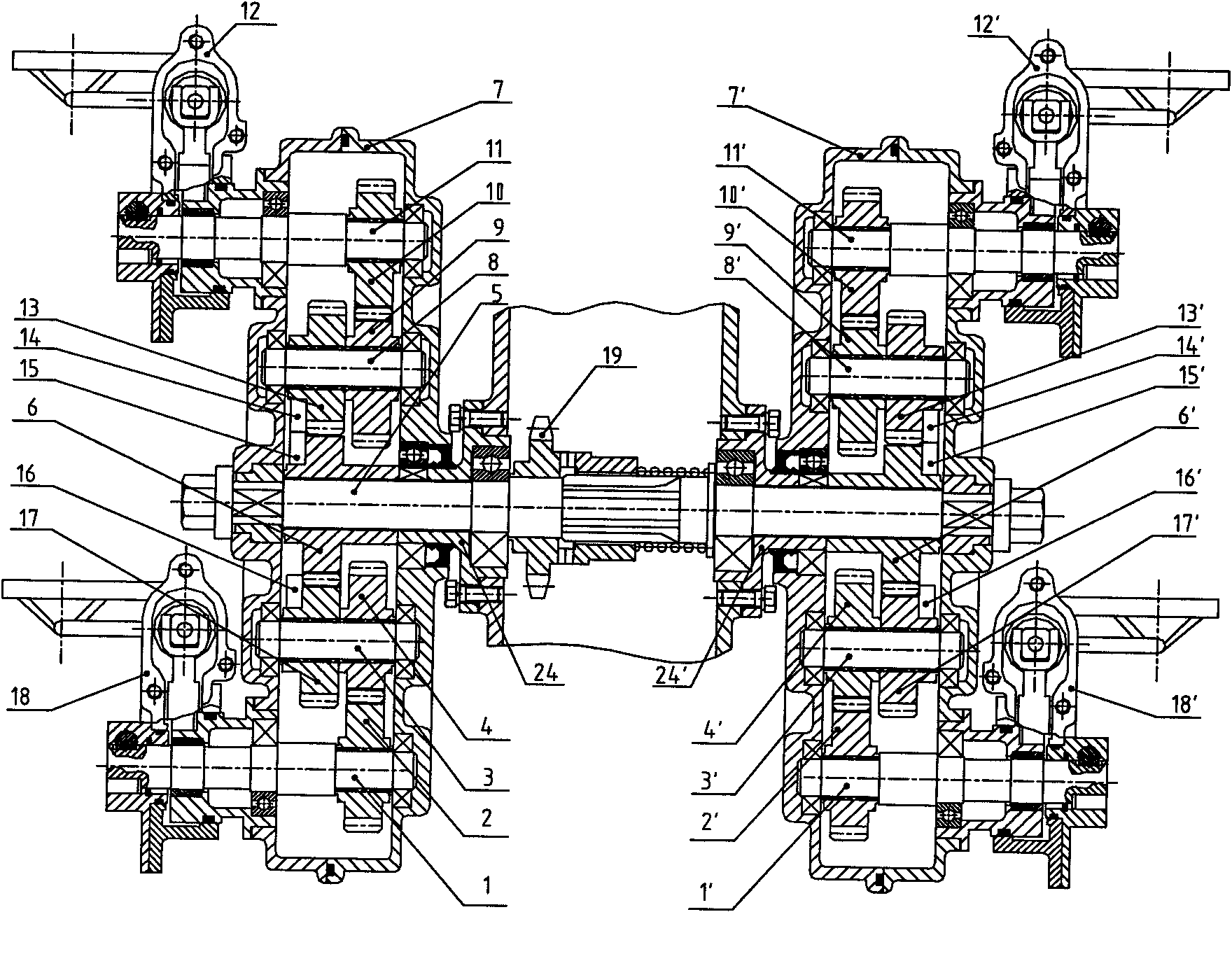

[0024] Such as figure 1 , figure 2 , image 3 Shown, the present invention it comprises transmission part and transplanting arm part; Transmission part comprises driving sprocket wheel 22 on the power transmission shaft 23 in the sprocket case 21, and is contained on the sprocket case 21 inner central shaft 5 through chain 20. The central sprocket 19 is connected, and the left and right gear boxes 7, 7' with the same structure and symmetrical arrangement are fixed on the left and right shaft ends of the central shaft 5 extending out of the sprocket box 21; wherein:

[0025] The left end of the central shaft 5 in the left gear box 7 is equipped with a left center incomplete circular gear 6 fixed on the sprocket case 21 through a left flange 24, and the left central incomplete circular gear 6 is fixedly connected with a left convex lock Arc (that is, equivalent to a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com