Household rice polisher

A rice polishing machine, home-use technology, applied in the field of rice polishing machine, can solve the problems of poor quality, moldy and long insects, little further attention to whether the rice is fresh or not

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

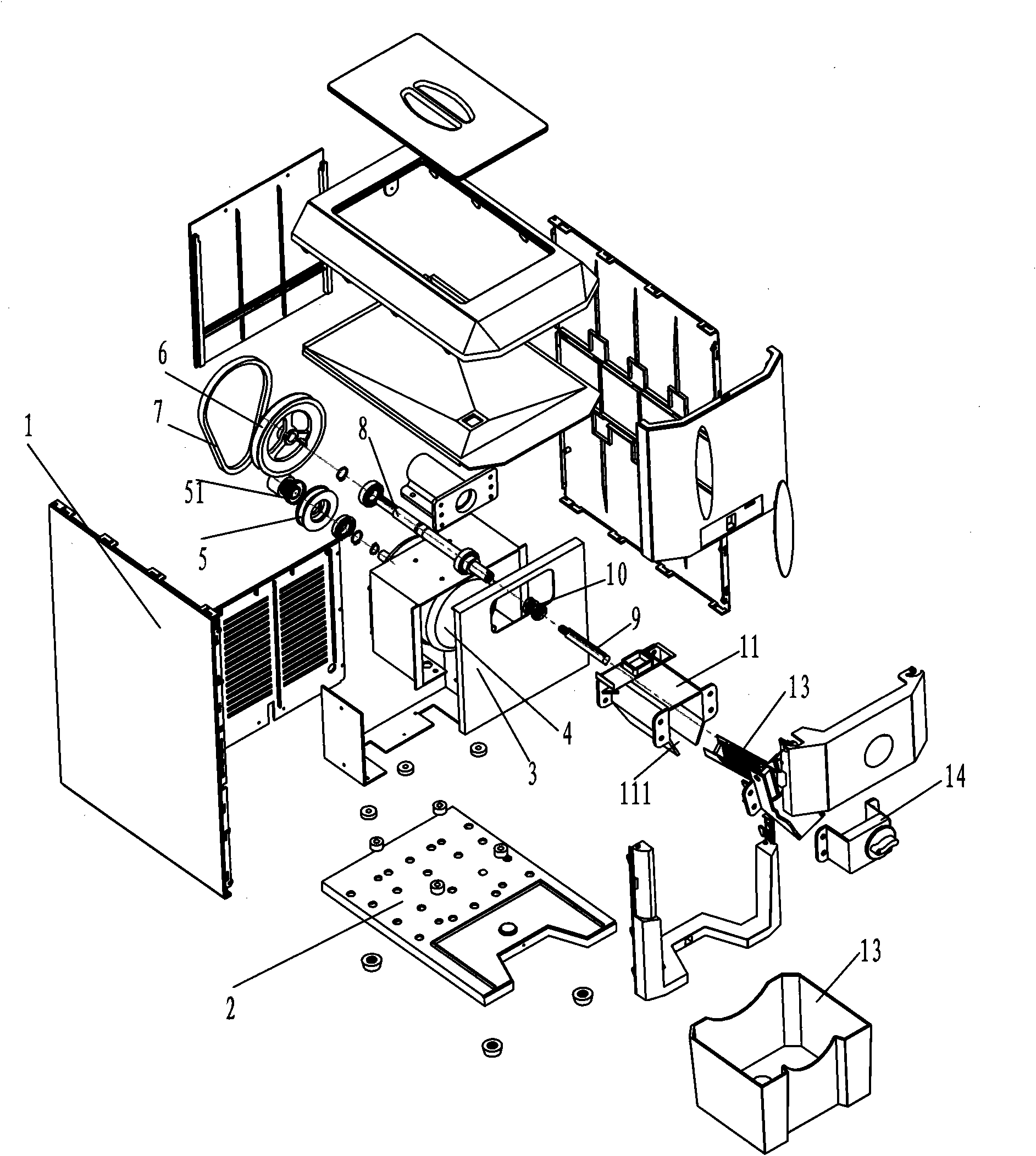

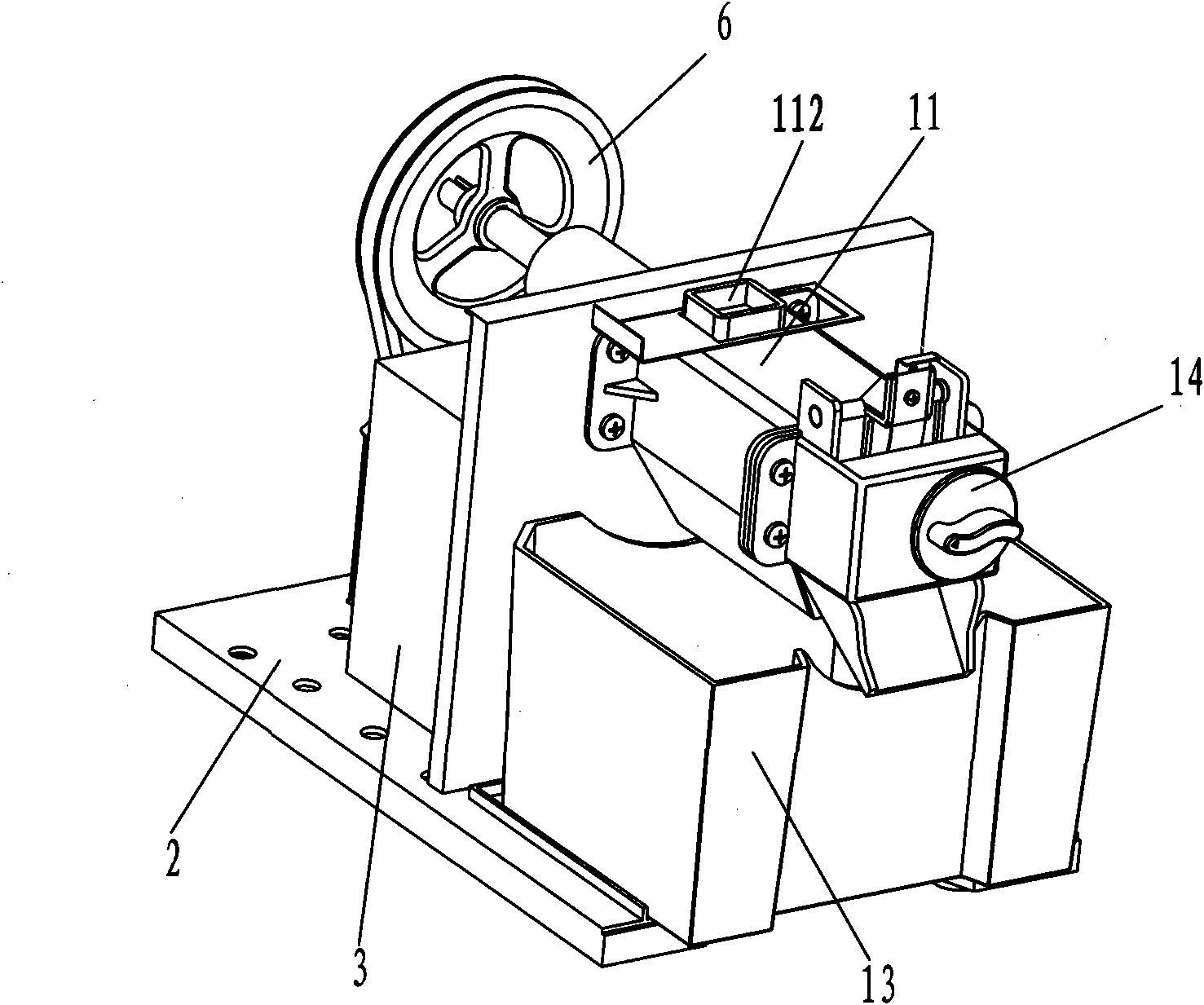

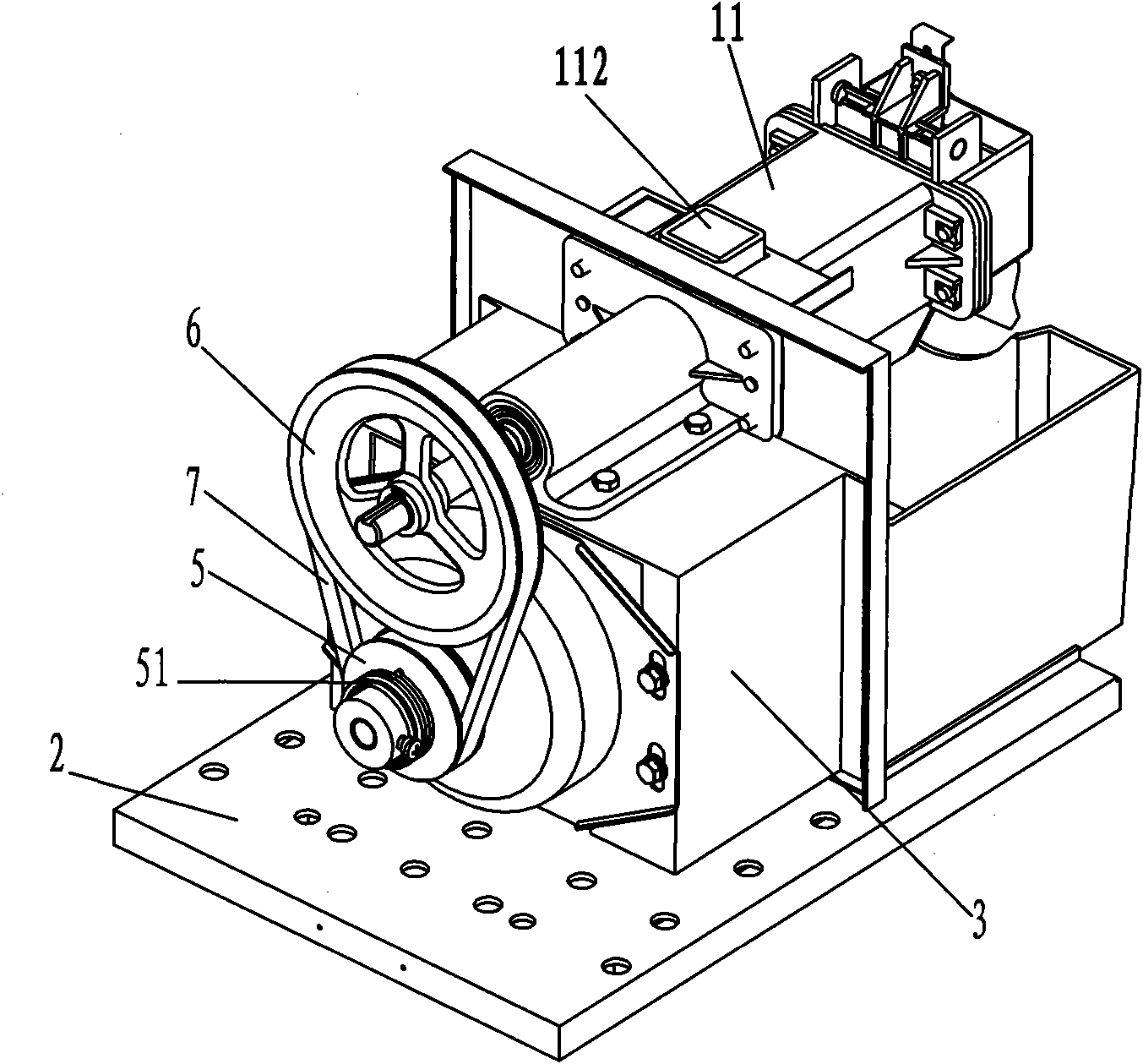

[0014] Such as Figure 1-5 As shown, a household rice polishing machine includes a casing 1, a base 2 is arranged in the casing 1, a bracket 3 is arranged at the rear of the base 2, a drive motor 4 is arranged on the bracket 3, and the output shaft of the drive motor 4 A driving pulley 5 is provided, and a booster torsion spring 51 is also provided between the driving pulley 5 and the output shaft; a transmission shaft 8 is provided above the driving motor 4, and the transmission shaft 8 is fixed on the bracket 3 through a bearing and a sleeve. The rear end of the transmission shaft 8 is also provided with a passive pulley 6, the driving pulley 5 and the passive pulley 6 are connected by a transmission belt 7, and the front end of the transmission shaft 8 is connected with a rice processing warehouse; the rice processing warehouse includes a cylindrical separation The machine 11, the screen 12, the polished rice knife 9 and the conveying threaded steel wire 10 are sleeved on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com