Milling and turning composite machining tool with turning tool row device and lathe tool changing mechanism

A tool changing mechanism and composite machining technology, which is applied to metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problem that the milling and turning composite machining machine cannot realize the intensification and automatic control of the milling process and turning process, affecting the milling and turning process. The degree of automation of compound processing machine tools, the inability to realize automatic tool clamping and tool change of turning tools, etc., achieve the effect of improving processing production efficiency, realizing intensification, and improving angle positioning control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

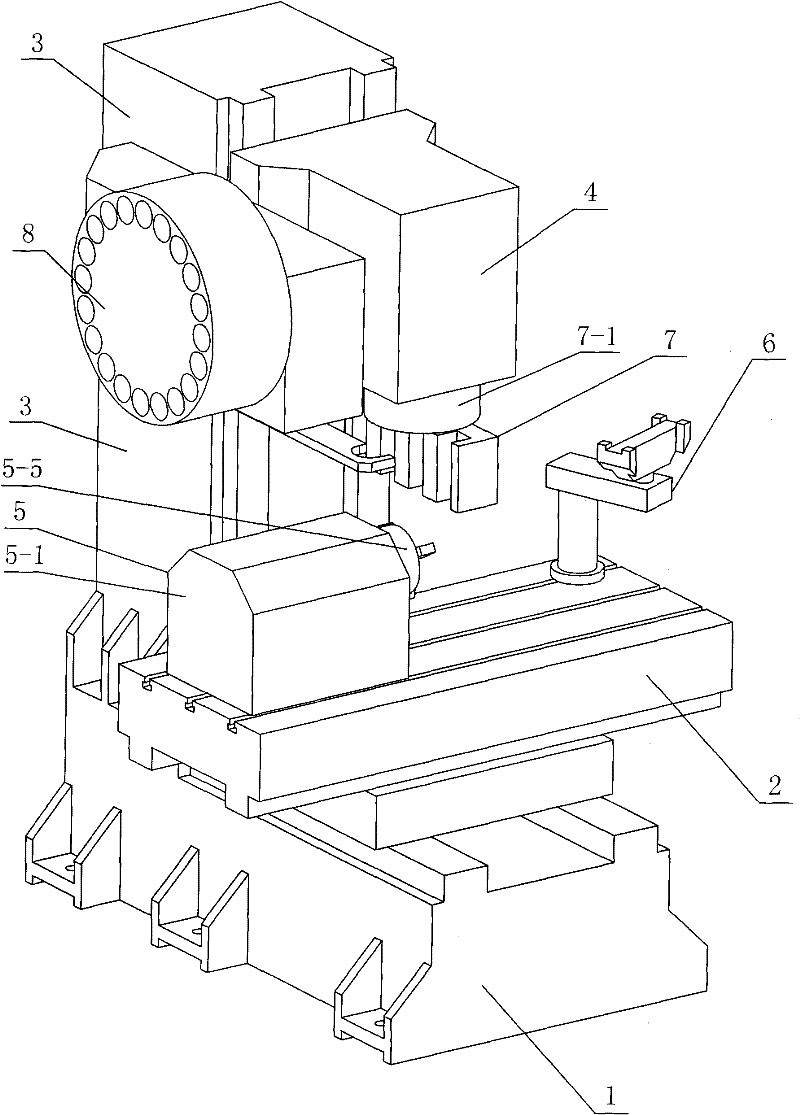

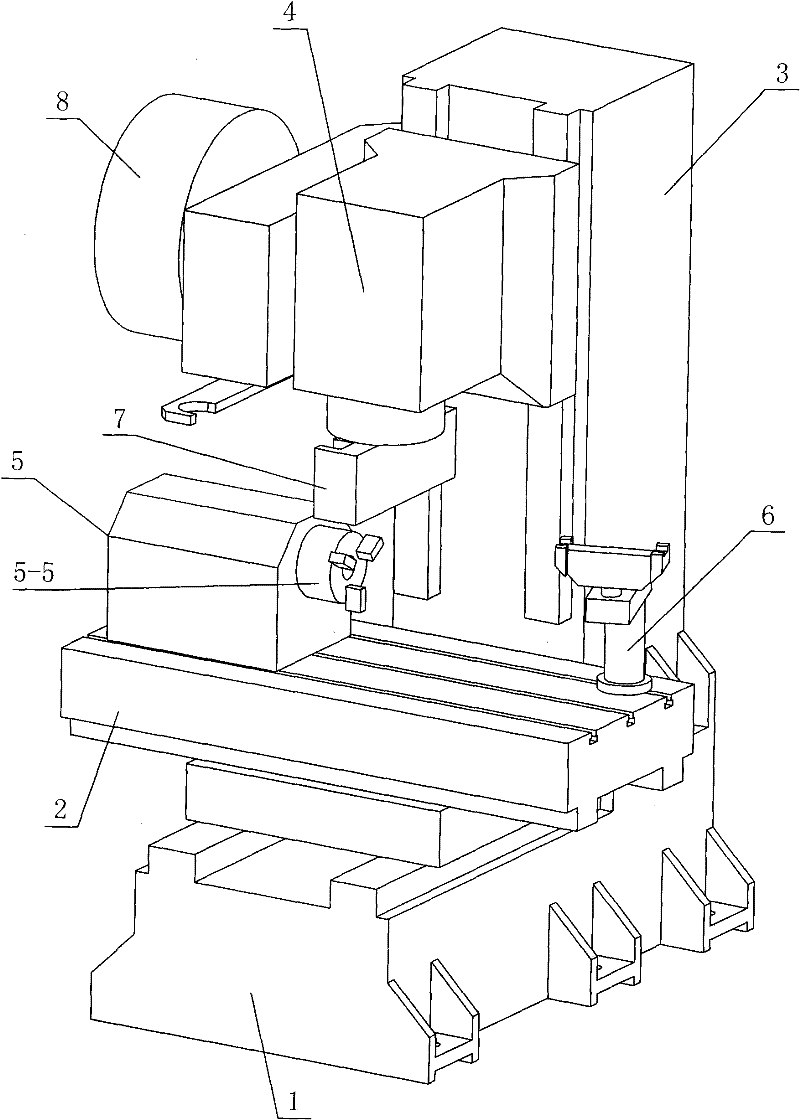

[0020] Specific implementation mode one: as Figure 1-13 As shown, the milling-turning composite processing machine tool with the turning tool row device and the lathe tool changing mechanism described in this embodiment, the composite processing machine tool includes a milling machine main body, and the milling machine main body includes a saddle 1, a workbench 2, a column 3 and the headstock 4, the workbench 2 is horizontally located above the saddle 1 and the two are arranged in a cross shape, the column 3 is located at the rear end of the workbench 2 and the lower end of the column 3 is connected with the slide saddle 1, and the headstock 4 is located on the workbench 2 and the spindle box 4 is slidingly connected with the column 3; the compound processing machine tool also includes a lathe spindle assembly 5, a lathe tool changing mechanism 6 and a turning tool row device 7, and the lathe spindle assembly 5 is arranged on the top of the workbench 2 The left end is sliding...

specific Embodiment approach 2

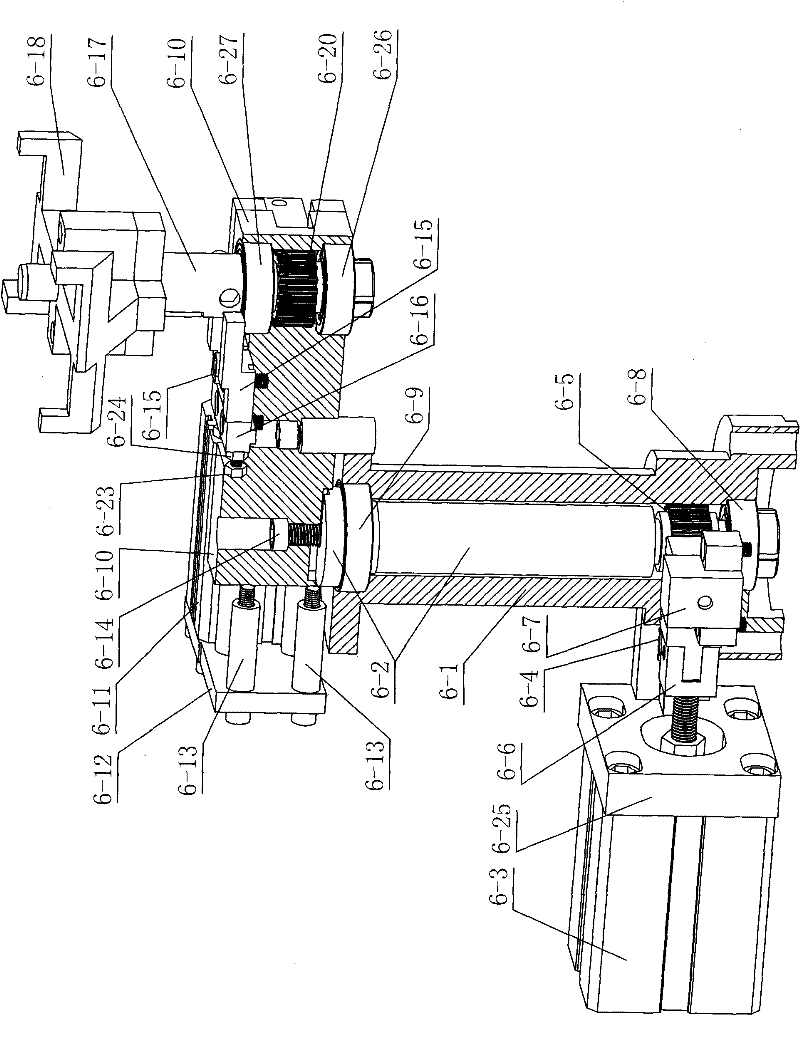

[0025] Specific implementation mode two: as image 3 and Figure 4 As shown, the lathe tool change mechanism 6 in this embodiment also includes a fork-shaped connecting piece 6-6 and a first cylinder connecting plate 6-25, and the piston connecting rod of the first cylinder 6-3 passes through the fork-shaped connecting piece 6-6. It is connected with the first rack 6-4, and the first cylinder 6-3 is connected with the lower end side wall of the shaft sleeve 6-1 through the first cylinder connecting plate 6-25. Such arrangement makes the structure more compact and facilitates assembly. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: as image 3 and Figure 4 As shown, the lathe tool changing mechanism 6 in this embodiment also includes a second cylinder connecting plate 6-12, a second cylinder connecting plate connecting piece 6-13 and a second rack connecting plate 6-21, and the second cylinder connecting plate 6-12 is connected with the rocker arm 6-10 through the second cylinder connection plate connector 6-13, and the second cylinder 6-11 is installed on the second cylinder connection plate 6-12. Such arrangement makes the structure more compact and facilitates assembly. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com