Ordered porous silica and silicon carbonitride and preparation method and application thereof

A technology of porous silica and silicon carbonitride, applied in porous silica, ordered porous silica, preparation of the ordered porous silica and ordered porous carbonitride, porous carbonitride Silicon field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

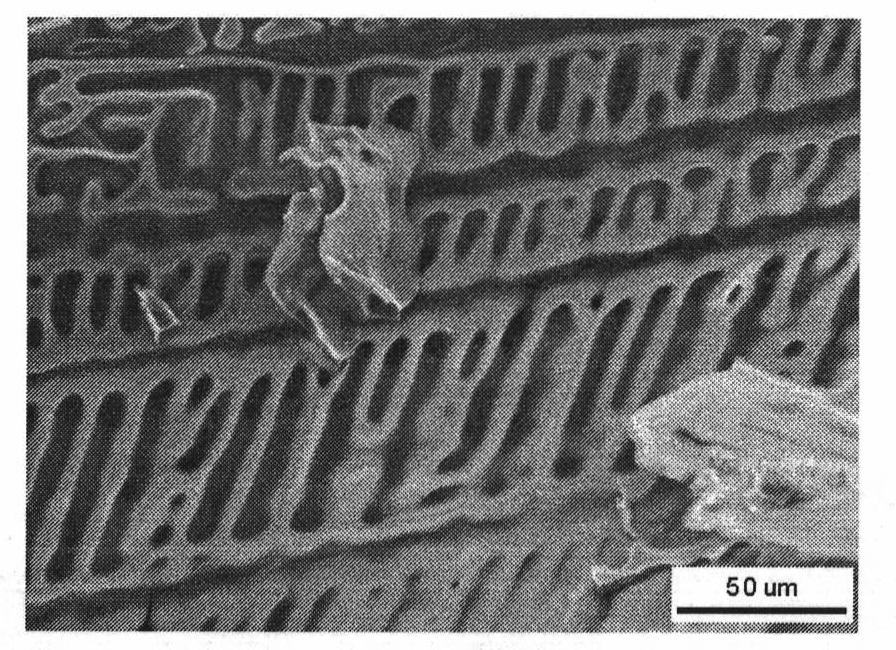

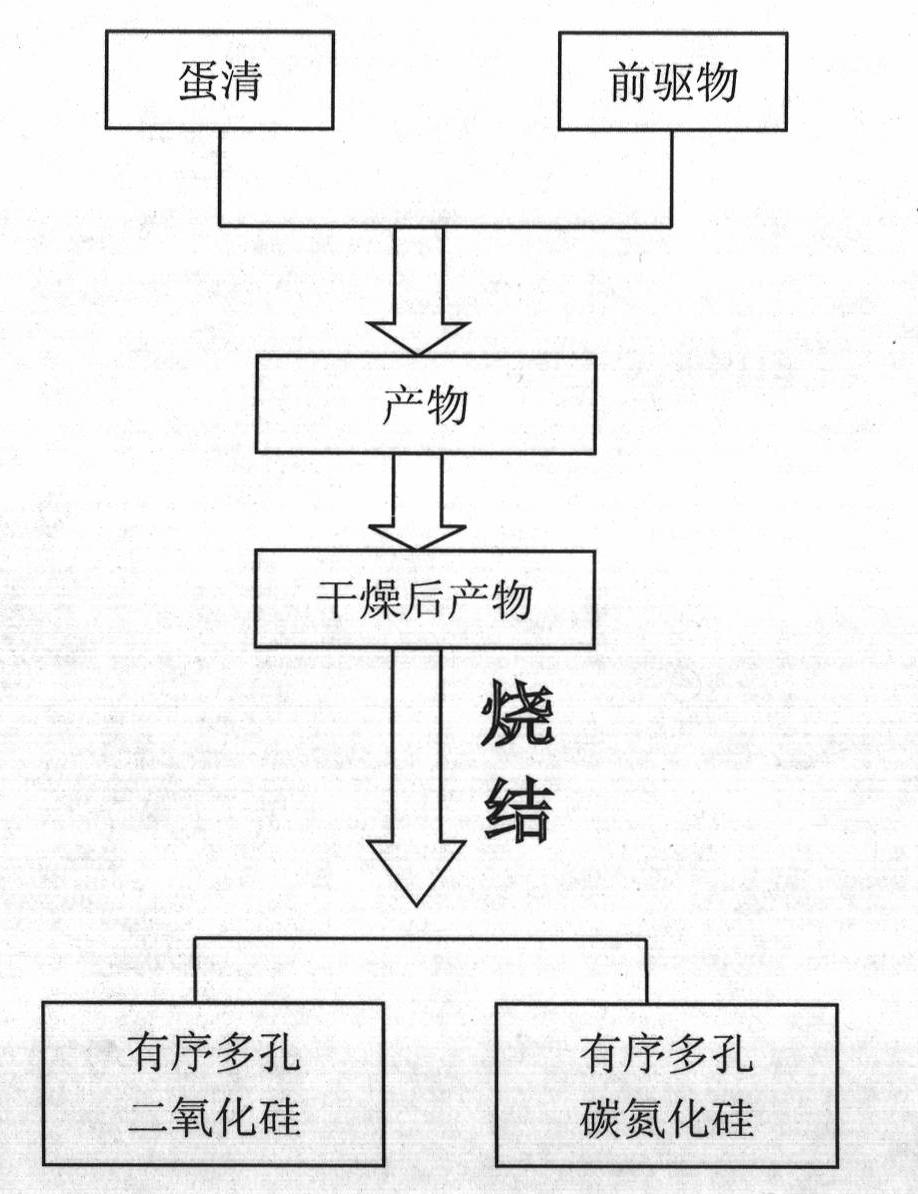

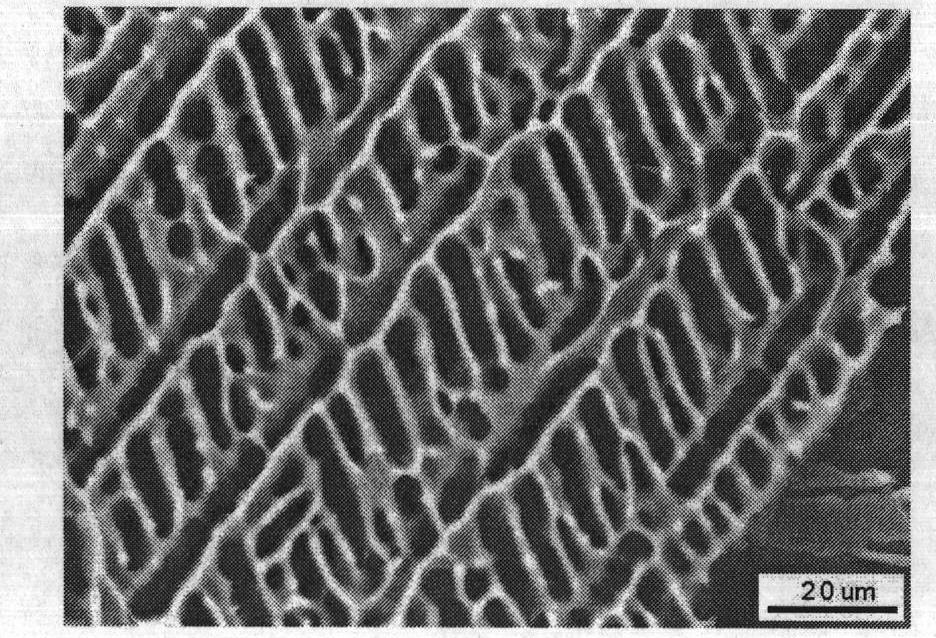

[0034] Example 1: At 30°C, 10 grams of egg whites were vigorously stirred for 2 hours, and the egg whites became foamy. 1 g of tetraethyl silicate was added and stirring was continued for 30 hours. After the reaction, the mixture was dried to obtain the egg white-silica complex (see image 3 ), baked at 550°C for 6 hours to remove the protein template, and an ordered porous silica material was obtained (see Figure 4 ). This material replicates the structure of egg white, the pores are orderly, the pores are rectangular, about 8-20 microns long, 1-3 microns wide, and the specific surface area is 62.72m 2 / g. Its XRD and FT-IR spectrum see Figure 5 with Image 6 .

Embodiment 2

[0035] Example 2: At 30°C, 10 grams of egg whites were vigorously stirred for 2 hours, and the egg whites were foamy. 1 g of tetraethyl silicate was added and stirring was continued for 30 hours. After the reaction, the mixture was dried to obtain the egg white-silica complex (see image 3 ), and fired in an argon atmosphere at 1300°C for 3 hours to obtain an ordered porous silicon carbonitride material (see Figure 7 ). This material replicates the structure of egg white, the pores are orderly, the pores are rectangular, about 5-20 microns long, 1-3 microns wide, and the specific surface area is 76.05m 2 / g. Its XRD and FT-IR spectrum see Figure 8 with Figure 9 .

Embodiment 3

[0036] Example 3: At 20° C., 40 grams of egg whites were vigorously stirred for 3 hours, and the egg whites became foamy. 1 g of tetraethyl silicate was added and stirring was continued for 8 hours. The reaction mixture was dried, and the obtained egg white-silicon dioxide composite was calcined at 550° C. for 6 hours to remove the protein template to obtain an ordered porous silica material. This material also replicates the structure of egg white, the pores are orderly, the pores are rectangular, about 8-20 microns long, 1-3 microns wide, and the specific surface area is 39.40m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com